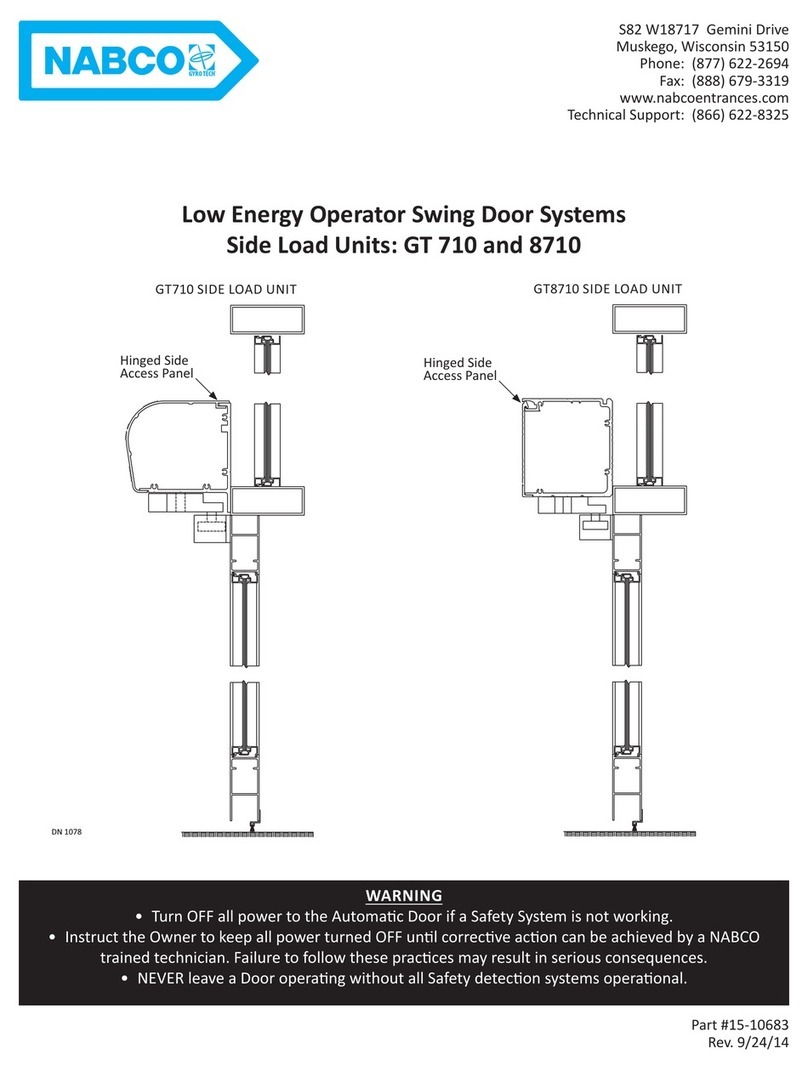

ALLOMATIC TORO 24 User manual

SWING GATE OPENER

INSTALLATION MANUAL

®

TORO 24

UL325

Compliant

Compliant

Compliant

UL991

CSA C22.2

Canada

L

I

S

T

E

D

®

US

Compliant

Copyright © 2017 all-o-matic inc. www.allomatic.net WWW.ALLOMATIC.NET

1

TABLE OF CONTENTS

SAFETY AND INTRODUCTION

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

UL 325 Cass Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION

Pull to Open Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Push to Open Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Entrapment Protection Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Loop Layout................................................11

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gate Travel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BOARD FEATURES

Setting and Diagnostic Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Gate Opening Direction Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programmable Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electronic Reversing Device (ERD) Adjustment . . . . . . . . . . . . . . . . . . . . 18

Timer Adjustment and Radio Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dip Switch Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

LED Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WIRING ACCESSORIES TO CONTROL BOARD

Accessory Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Monitored Entrapment Protection Device Connection . . . . . . . . . . . . . 23-24

Loop Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Three-Button Station Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Magnetic/Solenoid Lock Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Radio Receiver Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SOLAR INSTALLATION

Solar Panel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

External Solar System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

EMERGENCY RELEASE INSTRUCTIONS............................31

WARRANTY AND CUSTOMER RECORD.............................32

PARTS BREAKDOWN..................................Check Website

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF :INJURY

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS. DO NOT START INSTALLATION UNTIL

YOU HAVE READ AND UNDERSTAND THESE DIRECTIONS. IF THERE IS SOMETHING YOU DO NOT

UNDERSTAND, PLEASE CALL US.

NEVER let children operate or play with gate controls.

Locate the control station and make sure it is (a) within sight of the gate and (b) at a minimum height of 5

feet so small children cannot reach it.

Install the enclosed entrapment warning signs next to the control station and in a prominent location.

For operators equipped with a manual release, instruct the end user on the correct operation of the manual

release. Use the manual release only when the gate is not moving. It is advised that the power be turned

off.

Always keep people and objects away from the gate. No one should cross the path of a moving gate.

The gate operator must be tested monthly. The gate must reverse on contact with a rigid object, or stop

when an object activates the non-contact sensor(s). Always re-test the operator after adjusting the limits

and/or force. Failure to adjust and re-test the gate operator properly may cause sever injury or death.

Keep gate(s) properly maintained. Have a qualified service technician make repairs to gate hardware and

make proper adjustments to gate operator.

This gate entrance/exit is for vehicles only. Pedestrians must use a separate entrance.

There is nothing on a gate operator that is easily repaired or adjusted without a great deal of experience.

Call a qualified gate service technician who knows your gate operator.

SAVE THESE INSTRUCTIONS

3

IMPORTANT SAFETY INSTRUCTIONS (CONTINUED)

BEFORE GATE OPERATOR INSTALLATION

ŸConfirm that the gate operator being installed is

appropriate for the application.

ŸConfirm that the gate is designed and built

according to the current published industry

standards.

ŸConfirm that all appropriate safety features and

safety accessory devices are being installed,

including all entrapment protection devices.

ŸMake sure that the gate opens and closes freely

(by hand) before installing the operator.

ŸRepair or replace worn or damaged gate

hardware before installing the gate operator.

ŸEliminate all gaps in the sliding gate below a 6

foot height that permits a 2 1/4” sphere to pass

through any location. This includes the area of

the adjacent fence covered when the gate is in

the open position

ŸEliminate all gaps in a swing gate below a 4 foot

height that permits a 4” sphere to pass through

any location. This includes the hinge area of the

gate.

GATE OPERATOR INSTALLATION

ŸOperator must be disconnected from the power

source before attempting any installation of

accessories.

ŸInstall gate operator according to the installation

instructions in this manual.

ŸAdjust the operator clutch or load sensing device

to the minimum force setting that will allow for

reliable gate operation.

ŸInstall the operator inside the fence line. Do not

install the operator on the public side of the fence

line.

ŸInstall a proper electrical ground to the gate

operator.

ŸControls intended for user activation must be

located at least 6 feet away from any moving part

of the gate, and where the user is prevented

from reaching over, under, around, or through

the gate to operate the controls.

ŸOutdoor or easily accessible controls shall have

a security feature to prevent unauthorized use.

ŸThe stop and/or reset button must be located in

the line of sight of the gate. Activation of the

operator reset control shall not cause the

operator to move.

ŸInstall a minimum of 2 warning signs, one on

each side of the gate where they are easily

visible.

ŸTake pictures of the installation.

ŸTest all safety features for proper function before

placing the automatic vehicular gate in

operation.

MAINTENANCE

ŸTrain owners/users on the basic functions and

safety features of the gate system, including

how to turn off the power and operate the

manual disconnect feature.

ŸLeave safety instructions, product literature,

installation manual, and maintenance manual

with the owner or end user.

ŸExplain to the owner or end user the importance

of routine service and operator testing on a

monthly basis.

INSTALL THE GATE OPERATOR ONLY WHEN YOU

HAVE READ THE FOLLOWING

4

UL 325 CLASS TYPES AND OBSTRUCTIONS SENSING SYSTEMS

UL 325 CLASS TYPES

CLASS ONE: RESIDENTIAL

ŸA vehicular gate operator intended for use in

garages or parking areas associated with a

residence of one to four single families.

CLASS TWO: COMMERCIAL OR GENERAL

PUBLIC ACCESS

ŸA vehicular gate operator intended for use at a

commercial location or building, such as a

multi-family housing unit (five or more single

family units), hotel, garages, retail stores, or

other buildings accessible by or servicing the

general public.

CLASS THREE: INDUSTRIAL OR LIMITED

ACCESS

ŸA vehicular gate operator intended for use at

an industrial location or building, such as a

factory, loading dock area, or other locations

not accessible by or intended to service the

general public.

CLASS FOUR: RESTRICTED ACCESS

ŸA vehicular gate operator intended for use at a

guarded industrial location or building, such as

airport security areas or other restricted

access locations not servicing the general

public and where unauthorized access is

prevented via supervision by security

personnel.

THE SIX TYPES OF OBSTRUCTION

SENSING SYSTEMS

TYPE A:

ŸInherent entrapment protection system. This

system must sense and initiate the reverse of

the gate within 2 seconds of contact with a

solid object.

TYPE B1:

ŸNon-contact sensor (photoelectric sensor or

equivalent). This system shall, upon sensing

an obstruction in the direction of the gate

travel, reverse the gate within a maximum of 2

seconds.

TYPE B2:

ŸContact sensor (edge device or equivalent).

This system shall, upon sensing an obstruction

in the direction of the gate travel, initiate the

reversal of the gate within a maximum of 2

seconds.

TYPE C:

ŸInherent force limiting, inherent adjustable

clutch, or pressure relief valve.

TYPE D:

ŸActuating device requiring continuous pressure

to maintain opening or closing motion of the

gate.

Each class must have (2) monitored entrapment protection devices in each entrapment zone to sense and react

to obstructions within 2 seconds.

All-O-Matic’s gate operators conform to the most rigid Class One.

5

OPERATOR SPECIFICATIONS

Max Gate Weight

8’ wide gate - 1,600 lbs.

12’ wide gate - 1,200 lbs.

Max Gate Length

16’ wide gate - 800 lbs.

18’ wide gate - 600 lbs.

Warranty

4 year residential

3 year commercial

Motor

24 VDC Motor

Gate Speed

Adjustable 15-20 seconds

per 90 degree opening

Power

115 VAC single phase - 4 amps

230 VAC single phase - 2 amps

or 12/24 VDC solar panel up to 80 watts

Duty Cycle

Continuous

Temperature Range

-40º to 160º

Gear Box Ratio

N/A

Dimensions

Fully retracted arm: 38-39”

Fully extended arm: 59”

Shipping Weight

Arm: 24 lbs.

Control box: 55 lbs.

Emergency Release

Keyed manual release

Belt Size

N/A

Main Sprocket

N/A

Chain Size

N/A

Gear Box Sprocket

N/A

Limit Shaft Sprocket

N/A

Breaker Requirement

20 amp dedicated

Gearbox Pulley

N/A

Motor Pulley

N/A

UL Classes

I & II

TORO 24

6

PARTS IDENTIFICATION

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

ALL-O-MATIC INC.

<ENG. ESP.>

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

1 2 3 4 5 6 7 8

-----------------------OPEN------------------------

5

5

MOTOR 1

MOTOR 2

SINGLE/DUAL

IN/OUT

24V AC

LINE IN EXTERNAL

S/N:

DATE:

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

OPEN

ERD

CLOSE

ERD

TIMER

GATE OPERATOR

BACK MOUNTING

PLATE

BACK MOUNTING

BRACKET

FRONT GATE

BRACKET

(2) EMERGENCY

RELEASE KEY

(2) PIVOT

PINS

PIVOT PIN

SECURE

SETSCREW

Exit Loop

Phantom Loop

Safety Loop

See side for

Jumper setting

Loop Connections

Exit

Loop

Loop

Loop

Safety

Phantom

24VAC/

12VDC

Ground

Exit

Phantom

Safety

LPR-1

LOOP RACK

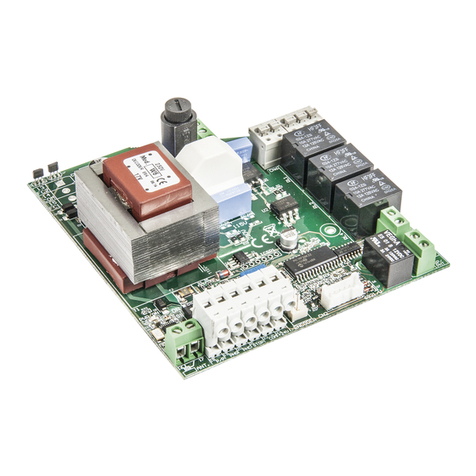

TORO CONTROL BOARD

(2) 7AH BATTERY

TRANSFORMER

CONTROL BOX

ŸThe back mounting bracket must be cut to fit the arm geometry.

Ÿ Use the back mounting plate when a steel post is not available to weld the back mounting bracket on to.

7

PULL TO OPEN INSTALLATION

OUTSIDE PROPERTY

INSIDE PROPERTY

C

GEOMETRY OPTIONS

OPTION A B C SPEED

1 7” 5” 58” 15 SEC 90º OPENING

2 8” 6” 58” 17.5 SEC 90º OPENING

3 7.5” 7.5” 58” 19 SEC 90º OPENING

CLOSED POSITION

OPEN POSITION

For proper operation, use the installation measurements in the chart below.

If necessary, modify the gate construction for best automation performance.

Before proceeding with the gate operator installation, be sure of the following:

- The gate moves open and close freely when on manual.

- The gate hinges are properly positioned and lubricated.

- There are no obstructions in the path of the gate.

- There is no friction between the gate or ground when the gate is in motion.

B

8

PUSH TO OPEN INSTALLATION

For proper operation, use the installation measurements in the drawing below. A custom bracket is required for

this type of installation.

If necessary, modify the gate construction for best automation performance.

Before proceeding with the gate operator installation, be sure of the following:

- The gate moves open and close freely when on manual.

- The gate hinges are properly positioned and lubricated.

- There are no obstructions in the path of the gate.

- There is no friction between the gate or ground when the gate is in motion.

OUTSIDE PROPERTY

INSIDE PROPERTY

8”

58”

6”

CLOSED POSITION

OPEN POSITION

CUSTOM BRACKET

REQUIRED

(NOT PROVIDED)

9

OPERATOR INSTALLATION

WIRE CONNECTION:

(1) Avoid tension in the cable during open and close cycles.

(2) Always connect the grounding wire (GND)

6

5

3

2

1

no.1

no.2

A

B

4

7

1

White

Yellow

Red

White

Black

+5V

INDEX

COMMON

Limit Switch (Limit 1)

Limit Switch (Limit 2)

1

2

3

4

5

Motor (+)

Motor (-)

6

7

Blue

Green

Use the back mounting plate to have a welding surface when a steel post is not available. Use anchor bolts to

mount the plate to existing surface.

Cut the back mounting bracket to fit the geometry and weld the bracket to the steel post or back mounting plate.

NOTE: A custom mounting plate is required for gates that open to the outside. See “Push to Open” installation

page.

Remove the wire connection cover on the arm and attach the back mounting bracket with the pin.

Release the gate operator and place the pin into the fitting position no.1 and no.2, as shown below. Use the

setscrew to hold pin no.2 in place.

Make sure that the gate operator is mounted in a horizontal position.

Prior to welding the front gate bracket to the gate leaf, make sure to cover the gate operator to prevent any

damage from welding sparks.

10

ENTRAPMENT PROTECTION INSTALLATION

ŸA minimum of (2) monitored entrapment protection devices are REQUIRED for each entrapment zone.

ŸAn entrapment zone is a location or point of contact where a person can become entrapped between a moving

gate and a rigid object.

ŸThe operator is equipped with an inherent entrapment protection system (ERD).

ŸThe gate operator requires an external monitored entrapment protection device (non-contact photoelectric

sensor or contact edge) for each entrapment zone prior to gate operation. The operator cycles power to the

external entrapment protection device and checks for device signals. If the operator does not receive the

correct feedback from the device, the gate will not operate.

ENTRAPMENT ZONE

ENTRAPMENT ZONE

OUTSIDE PROPERTY

INSIDE PROPERTY

EDGE SENSOR FOR

CLOSE CYCLE - INSTALLED

VERTICALLY ON GATE FRAME

EDGE SENSOR

FOR OPEN CYCLE -

INSTALLED VERTICALLY

ON GATE FRAME

EDGE SENSOR

FOR OPEN CYCLE -

INSTALLED HORIZONTALLY

ON BOTTOM GATE FRAME

PHOTOELECTRIC

SENSOR FOR

CLOSE CYCLE

PHOTOELECTRIC

SENSOR FOR

OPEN CYCLE

ENTRAPMENT PROTECTION IS

REQUIRED FOR AREA BETWEEN

THE OPEN GATE AND GATE

OPERATOR AS WELL AS BETWEEN

THE GATE AND THE CURB.

CURB

11

LOOP LAYOUT

— Below is a typical loop layout. When connecting to an All-O-Matic circuit board, use the following:

— Safety Loop - Normally Closed (N.C) Contacts

— Center/Phantom Loop - Normally Open (N.O.) Contacts

— Exit Loop - Normally Open (N.O.) Contacts

— Wires MUST be twisted from the exit point of the loop saw cut to the gate operator.

—Twist loop wires 6 turns per foot, as shown below. Improper twisting of wires can cause loop issues.

— When using an inside and outside safety loop, loops must be WIRED IN SERIES.

OUTSIDE SAFETY LOOP

INSIDE SAFETY LOOP

CENTER/PHANTOM LOOP

5 FT

5 FT

5 FT

5 FT

5 FT 5 FT

EXIT LOOP

1/4 IN1/4 IN

1 1/2 IN

WIRED IN SERIES

WHEN USED

TWISTED 6 TURNS

PER FOOT

NOTE: IF WIRES ARE

NOT TWISTED, LOOP

WILL MALFUNCTION.

GATE IN OPEN POSITION

12

ELECTRICAL CONNECTION

ŸAll gate operators MUST be properly grounded. This minimizes or prevents damage due to electrical charge,

such as a near lightening strike or an electrical static discharge.

ŸUse a single wire for the ground. DO NOT splice two wires for the ground. If the wire breaks or is cut, replace it

with a single length wire. NEVER use two wires for the ground.

ŸCheck the local city code for proper earth ground rod type and grounding procedures.

OPERATORS MUST BE PROPERLY GROUNDED!

ŸUse a minimum of a 20-amp, dedicated circuit for power.

Power Connection

115 VAC

230 VAC Single Phase

LINE 1

115V HOT

230V LINE 1

LINE 2

115V NEUTRAL

230V LINE 2

GND

GROUND

GROUND

115V

GRD LINE 2 LINE 1

OFF

ON

OFF

ON

AC POWER

BATTERY

230V

NOTE: WHEN APPLYING

230V TO THE OPERATOR,

MAKE SURE VOLTAGE

SWITCH IS FLIPPED TO 230V

POWER AND

BATTERY

SWITCHES

13

GATE TRAVEL ADJUSTMENT

Step 1: Find the open and close limit switches on the bottom of the gate actuator.

Step 2: Loosen the limit switch screws to allow the switch to slide.

Step 3: Make the necessary adjustments to the limit switch.

Step 4: Tighten the screws to lock limit switch in place.

14

SETTING AND DIAGNOSTIC MENU DESCRIPTIONS

<ENG Press the left arrow button (<) to select English

ESP> Press the right arrow button (>) to select Spanish

SETTINGS MENU

ŸTIME & DATE

Set and/or edit the time and date.

ŸSPEED

MAX SPEED: Set the maximum operational speed of the

motor.

ACCELERATION: Set how fast the gate will accelerate

at motor start. This can be set at slow, medium,

or fast.

SLOW DOWN: Set the travel percentage where the motor

will start slowing down as it approaches the open

and close limit.

ŸPOWER

TORQUE: Set the torque level to low, medium, or high.

CURR. SENSE: Set the way the board reads current from

load. THLD (threshold) is the default setting

and is recommended for normal operation.

PRGV (progressive) is used in installations where

wind is a factor for the gate.

Ÿ7 DAY TIMER

EVENT 1: Set up to 10 programmable events.

EVENT ACT.: Set the event actions

OFF (Disabled) = Nothing happens

OPEN = Opens the gate once

OPEN & HOLD = Opens the gate and holds it

open. Only a close event or close

override command will close the gate

CLOSE = Closes the gate once

CLOSE & HOLD = Closes the gate and holds it

closed. Only an open event or open

override command will open the gate

AUX RELAY ON = Turns auxiliary relay on

AUX RELAY OFF = Turns auxiliary relay off

TIME: Set the time the action takes place.

DAYS (ACTIVE): Set the days the action is to be active.

Each day need to be manually turned on using

the right arrow (>) to toggle it on/off.

ŸLEAF DELAY

DELAY LEAF: Select the leaf to have the delay. This

function is used in dual gate applications only.

Leaf delay is for the open cycle of the selected

leaf. The close delay will be on the opposite leaf

of the one that is selected.

DELAY: Set the delay for the selected leaf.

ŸAUXILIARY RELAY

RELAY ACTION: Set the action of the relay function.

OFF: Relay is inactive

PRE-WARN SIGNAL: Relay is used to turn on a

strobe light or siren with a delay before the gate

starts moving. Adjustable up to 6 seconds.

MOVING SIGNAL: Relay is on and kept active

while the gate is in motion.

ALARM SIGNAL: Relay is on when the gate has

been tampered with. This is used as an alarm

sensor output.

OPENED SIGNAL: Relay is on and kept active

when the gate is in the fully open position.

CLOSED SIGNAL: Relay is on and kept active

when the gate is in the fully closed position.

Ÿ

SERVICE CYCLE

SERVICE CYCLE COUNT: Used to program a service call.

Set the number of cycles you want the gate to

run before the gate operator gives off an

audible double beep alarm. The alarm will off

every hour for 1 minute to let the customer

know that the gate needs service.

ŸLIMIT SW CONF.

INDEX: This is the default configuration. The limit uses a

hall effect sensor for speed control and to keep

track of the gate position.

BEMF: This option is used when the gate is to run only on

limit switches. NOTE: Not fully functional.

ŸSET TO DEFAULT

DEFAULT ALL: Resets all parameters (below) to factory

settings.

DEFAULT SPEED: Resets speed to 100%, acceleration to

fast, and the slow down to 90%.

DEFAULT POWER: Resets torque to medium and the

current sense to progressive.

DEFAULT 7/D TIMER: Disables all events and makes them

inactive.

DEFAULT LEAF DLY: Resets leaf selection to none and 0.0

seconds.

DEFAULT RLY FUNC: Resets relay function to off/inactive.

DEFAULT SVC C: Resets service counter to 00000.

DEFAULT SW CONF.: Resets limit switch configuration to

index.

DIAGNOSTICS MENU

ŸGATE STATUS: Provides status of gate (ie: opening, opened,

closing, closed, stopped, or stopped ERD)

ŸMETER: Provides status of battery voltage, line in voltage, motor 1

current draw, and motor 2 current draw.

ŸMOTOR ONE: Provides speed and position of gate travel of

motor 1.

ŸMOTOR TWO: Provides speed and position of gate travel of

motor 2.

ŸEVENT LOG: Provides the last 25 abnormal gate events to assist in

troubleshooting. The events are date and time

stamped as they happen.

ŸCYCLE COUNT: Provides life, month, day, and remaining service

cycle counts.

_______________________________________________________

15

SETTINGS MENU PROGRAMMING AND DIAGNOSTICS

SETTINGS MENU PROGRAMMING

ENTERING THE SETTINGS MENU

ŸPress the ENTER button twice to turn the LCD display on

ŸPress the left arrow (<) button to select English

ŸUse the arrows to select SETTINGS and press ENTER

ŸUse the up/down arrows to scroll through the menu list

ŸPress ENTER to make your selection

ŸUse the left arrow (<) to go back to the previous screen

SETTING THE TIME AND DATE

ŸFrom the SETTINGS menu, select TIME & DATE and press ENTER

ŸMove the cursor to TIME and press ENTER

ŸUse the right and left arrows to move between hours and minutes

ŸUse the up and down arrows to change the time

ŸPress ENTER to save the time

ŸMove the cursor to DATE and press ENTER

ŸUse the right and left arrows to move between the month, day, and

year.

ŸUse the up and down arrows to change the date

ŸPress ENTER to save the date

ŸUse the up and down arrows to scroll through the days of the week

ŸPress ENTER to save the day

SETTING MOTOR SPEED

ŸFrom the SETTINGS menu, select SPEED and press ENTER

ŸUse the up and down arrows to scroll through the sub menu and

press ENTER to edit desired setting

ŸThe MAX SPEED can be adjusted between 50-100%. Use the up

and down arrows to change the percentage and press ENTER to

save

ŸThe ACCELERATION can be set at slow, medium, and fast. Use the

up and down arrows to change the setting and press ENTER to

save

ŸThe SLOW/DOWN can be adjusted between 70-95%. Use the up

and down arrows to change the percentage and press ENTER to

save

SETTING MOTOR POWER

ŸFrom the SETTINGS menu, select POWER and press ENTER

ŸUse the up and down arrows to scroll through the sub menu and

press ENTER to edit the desired setting

ŸThe TORQUE can be set at low, medium, or high. Use the up and

down buttons to change the setting and press ENTER to save

ŸThe CURR. SENSE can be set at threshold (THLD) for normal

operation or progressive (PRGV) for windy areas. Use the up and

down arrows to make selection and press ENTER to save

SETTING THE 7 DAY TIMER

ŸFrom the SETTINGS menu, select 7/DAY TIMER and press ENTER

ŸSelect the EVENT you would like to program and press ENTER

ŸUse the arrows to select the ACTION and press ENTER to save

ŸUse the arrows to set the time for the action and press ENTER to

save

ŸSet the days you would like the action to take effect. Use the up and

down arrows to scroll through the days and the right arrow to toggle

the day on/off

ŸRepeat the steps above for each event (up to 10)

SETTING THE LEAF DELAY

ŸFrom the SETTINGS menu, select LEAF DELAY and press ENTER

ŸPress ENTER to select which leaf needs the delay. The cursor will

blink on the left side of DELAY LEAF

ŸUse the up and down arrows to toggle between ONE/TWO leaves

and press ENTER to save

ŸSelect DELAY and press ENTER. Use the up and down arrows to

set the delay between 0.00 and 6.0 seconds.

SETTING THE AUXILIARY RELAY

ŸFrom the SETTINGS menu, select AUXILIARY RELAY and press

ENTER

ŸUse the up and down arrows to select the function and press

ENTER

ŸIf PRE-WARN SIGNAL was selected, you must set the delay. use

the up and down arrows to set the pre-warn delay and press ENTER

to save.

ŸNOTE: An asterisk (*) will appear on the selected function

SETTING THE SERVICE CYCLE

ŸFrom the SETTINGS menu, select SERVICE CYCLE and press

ENTER

ŸPress ENTER to set the number of cycles

ŸUse the right and left arrows to move the cursor and the up and

down arrows to change the number. Press ENTER to save

SETTING THE LIMIT SWITCH CONFIGURATION

ŸFrom the SETTINGS menu, select LIMIT SW CONF. and press

ENTER

ŸPress ENTER to edit the setting. Use the up and down arrows to

toggle between INDEX and BEMF and press ENTER to save

RESETTING BACK TO DEFAULT

ŸFrom the SETTINGS menu, select SET TO DEFAULT and press

ENTER

ŸUse the up and down arrows to select the parameter you would like

to set back to factory default and press ENTER

ŸDEFAULT all will set every parameter back to factory settings.

_______________________________________________________

DIAGNOSTICS MENU

ENTERING THE DIAGNOSTICS MENU

ŸPress the ENTER button twice to turn the LCD display on

ŸPress the left arrow (<) button to select English

ŸUse the arrows to select DIAGNOSTICS and press ENTER

ŸUse the up/down arrows to scroll through the menu list

ŸPress ENTER to make your selection

ŸUse the up and down arrows to scroll through the sub menus and

gather data

ŸUse the left arrow (<) to go back to the previous screen

16

GATE OPENING DIRECTION SETTING

Ÿ Use OPEN IN/OUT dipswitch (#8) to change the opening direction of the operator.

Ÿ The direction of gate opening is determined from behind the gate operator.

Ÿ LEDs will show opening and closing direction when the gate is moving.

ŸOPEN IN/OUT switch “OFF” is for open in installations

ŸOPEN IN/OUT switch “ON” is for push out installations

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

ALL-O-MATIC INC.

<ENG. ESP.>

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

1 2 3 4 5 6 7 8

-----------------------OPEN------------------------

5

5

MOTOR 1

MOTOR 2

SINGLE/DUAL

IN/OUT

24V AC

LINE IN EXTERNAL

S/N:

DATE:

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

OPEN

ERD

CLOSE

ERD

TIMER

MON_12/24VDC

MON_CLOSE

MON_OPEN

STOP CMD

COMMON

COMMON

DIPSWITCH #8

OPEN IN/OUT

OUTSIDE PROPERTY

INSIDE PROPERTY

CLOSED POSITION

OPEN POSITION

OUTSIDE PROPERTY

INSIDE PROPERTY

58”

CLOSED POSITION

OPEN POSITION

OPEN IN OPEN OUT

17

PROGRAMMABLE RELAY

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

ALL-O-MATIC INC.

<ENG. ESP.>

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

1 2 3 4 5 6 7 8

-----------------------OPEN------------------------

5

5

MOTOR 1

MOTOR 2

SINGLE/DUAL

IN/OUT

24V AC

LINE IN EXTERNAL

S/N:

DATE:

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

OPEN

ERD

CLOSE

ERD

TIMER

MON_12/24VDC

MON_CLOSE

MON_OPEN

STOP CMD

COMMON

COMMON

DEVICE

DEVICE

POWER SUPPLY

SETTING THE AUXILIARY RELAY

ŸFrom the SETTINGS menu, select AUXILIARY

RELAY and press ENTER

ŸUse the up and down arrows to select the function

and press ENTER

ŸIf PRE-WARN SIGNAL was selected, you must set

the delay. use the up and down arrows to set the

pre-warn delay and press ENTER to save.

ŸNOTE: An asterisk (*) will appear on the selected

function

RELAY ACTIONS: Set the action of the relay function.

OFF: Relay is inactive

PRE-WARN SIGNAL: Relay is used to turn

on a strobe light or siren with a delay

before the gate starts moving.

Adjustable up to 6 seconds.

MOVING SIGNAL: Relay is on and kept

active while the gate is in motion.

ALARM SIGNAL: Relay is on when the gate

has been tampered with. This is used

as an alarm sensor output.

OPENED SIGNAL: Relay is on and kept

active when the gate is in the fully

open position.

CLOSED SIGNAL: Relay is on and kept

active when the gate is in the fully

closed position.

18

ELECTRONIC REVERSING DEVICE (ERD) ADJUSTMENT

All of our boards are equipped with an Electronic Reversing Device (ERD), which will cause the gate to

reverse direction when it comes into contact with an obstruction.

The amount of force required to reverse the gate’s direction depends on the ERD sensitivity setting.

If the gate reverses direction on its own without hitting an obstruction, the ERD is too sensitive. If the gate

does not reverse when it hits an obstruction, the ERD is not sensitive enough.

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

ALL-O-MATIC INC.

<ENG. ESP.>

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

CMX-309FB C

8.0000 M

535202

1 2 3 4 5 6 7 8

-----------------------OPEN------------------------

5

5

MOTOR 1

MOTOR 2

SINGLE/DUAL

IN/OUT

24V AC

LINE IN EXTERNAL

S/N:

DATE:

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

OPEN

ERD

CLOSE

ERD

TIMER

MON_12/24VDC

MON_CLOSE

MON_OPEN

STOP CMD

COMMON

COMMON COUNTER CLOCKWISE

MAXIMUM SENSITIVITY

(LESS FORCE TO STOP GATE)

CLOCKWISE

MINIMUM SENSITIVITY

(MORE FORCE TO STOP GATE)

O

U

R

3

6

B

S

3

O

U

R

3

6

B

S

3

OPEN

ERD

CLOSE

ERD

Other manuals for TORO 24

2

Table of contents

Other ALLOMATIC Gate Opener manuals

ALLOMATIC

ALLOMATIC SL-100 AC User manual

ALLOMATIC

ALLOMATIC TORO 24 User manual

ALLOMATIC

ALLOMATIC SW-300DC User manual

ALLOMATIC

ALLOMATIC DC Series User manual

ALLOMATIC

ALLOMATIC OH-200DC User manual

ALLOMATIC

ALLOMATIC TORO 24 User manual

ALLOMATIC

ALLOMATIC SL-90DC User manual

ALLOMATIC

ALLOMATIC SL-100AC User manual

ALLOMATIC

ALLOMATIC SW-350DC User manual

ALLOMATIC

ALLOMATIC SL-45 DC User manual