Allsteel Stride User manual

Allsteel Inc.

Muscatine, Iowa 52761-0071

www.allsteeloffice.com

ZAPE-E

343-2152G

(8/12)

Stride Installation Packet

Index

System Guidelines .........................................Pages 1 thru 3

Panel Frame Connections...................................Pages 4 thru 11

Base Raceway Cover Removal ....................................Page 12

Footed Panel Adjustment ......................................... Page 13

Low Profile Glass Installation ...............................Pages 14 thru 23

Panel Mounted Screen Installation ...........................Pages 24 thru 26

Glass Panel Mounted Screen Installation ......................Pages 27 thru 28

Trim Installation ..........................................Pages 29 thru 33

Panel Tile Installation .....................................Pages 34 thru 45

Non-Rail Based Off-Modular Installation.......................Pages 46 thru 55

Worksurfaces......................................Pages 46 thru 47

Panel ............................................Pages 48 thru 52

Storage ..........................................Pages 53 thru 55

Rail Based Off-Modular Installation...........................Pages 56 thru 68

Panel ............................................Pages 59 thru 65

Storage ................................................. Page 66

Worksurfaces......................................Pages 67 thru 68

Door Panel Installation ....................................Pages 69 thru 70

Power Pole and Trim Installation.............................Pages 71 thru 72

8-Wire Electrical Installation ................................Pages 73 thru 77

Data Terminal Installation ......................................... Page 78

Overhead Storage Installation...............................Pages 78 thru 85

Permanent Wall Hanger Installation ................................. Page 86

Worksurface Supports Installation............................Pages 87 thru 97

Countertop Installation ...................................Pages 98 thru 101

Spanning tile installation .................................Pages 102 thru 108

Pour des instructions en francais, appeler le 800-822-7653

Para instrucciones en espanol, llame al 800-822-7653

Stride

Installation Instructions

3430215200 J

Contents

System Guidelines. . . . . . . . . . . . . . . . . . . . . 1

Panel Frame Connections...............4

Base Raceway Cover Removal..........12

Footed Panel Adjustment ..............13

Low Prole Glass Installation ...........14

Glass Panel Mounted Screen Installation ..24

Trim Installation ......................25

Panel Tile Installation. . . . . . . . . . . . . . . . . . 33

Non-Rail Based Off Modular Installation ...43

Door Panel Installation ................52

Power Pole and Trim Installation.........53

8-Wire Electrical Installation ............55

Data Terminal Installation ..............60

Overhead Storage Installation...........60

Permanent Wall Hanger Installation ......68

Worksurface Supports Installation........69

Countertop Installation. . . . . . . . . . . . . . . . . 80

Spanning Tile Installation. . . . . . . . . . . . . . . 84

Allsteel Inc.

Muscatine, Iowa 52761-0071

www.allsteeloffice.com

ZAPE-E

343-2152G

(8/12)

Stride Installation Packet

Index

System Guidelines .........................................Pages 1 thru 3

Panel Frame Connections...................................Pages 4 thru 11

Base Raceway Cover Removal ....................................Page 12

Footed Panel Adjustment ......................................... Page 13

Low Profile Glass Installation ...............................Pages 14 thru 23

Panel Mounted Screen Installation ...........................Pages 24 thru 26

Glass Panel Mounted Screen Installation ......................Pages 27 thru 28

Trim Installation ..........................................Pages 29 thru 33

Panel Tile Installation .....................................Pages 34 thru 45

Non-Rail Based Off-Modular Installation.......................Pages 46 thru 55

Worksurfaces......................................Pages 46 thru 47

Panel ............................................Pages 48 thru 52

Storage ..........................................Pages 53 thru 55

Rail Based Off-Modular Installation...........................Pages 56 thru 68

Panel ............................................Pages 59 thru 65

Storage ................................................. Page 66

Worksurfaces......................................Pages 67 thru 68

Door Panel Installation ....................................Pages 69 thru 70

Power Pole and Trim Installation.............................Pages 71 thru 72

8-Wire Electrical Installation ................................Pages 73 thru 77

Data Terminal Installation ......................................... Page 78

Overhead Storage Installation...............................Pages 78 thru 85

Permanent Wall Hanger Installation ................................. Page 86

Worksurface Supports Installation............................Pages 87 thru 97

Countertop Installation ...................................Pages 98 thru 101

Spanning tile installation .................................Pages 102 thru 108

Pour des instructions en francais, appeler le 800-822-7653

Para instrucciones en espanol, llame al 800-822-7653

Allsteel Inc.

Muscatine, Iowa 52761-0071

www.allsteelofce.com

343-2152G

PAGE 1 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 1

Illustration 2

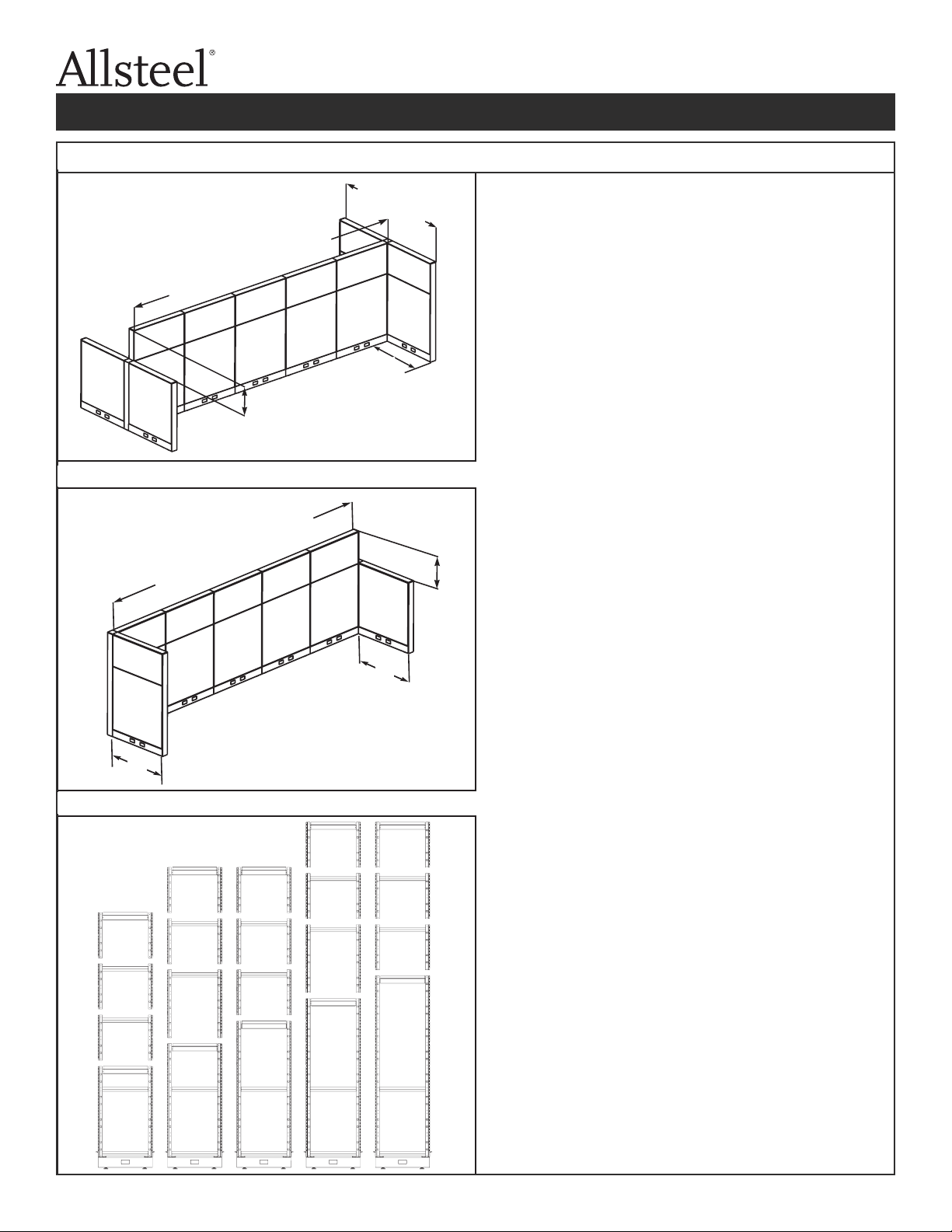

STRAIGHT PANEL GUIDELINES:

Definitions:

Parent Panel Run - Panels (or a single panel)

configured in a straight line intended to divide space.

It is usually longer than the panels used to stabilize it.

Return Panels - Panels attached to a parent run for

the purpose of stabilizing it.Return panels may also

have the effect of dividing space.

FOR ADEQUATE STABILITY of the Allsteel Stride

freestanding wall partitions, one of two methods of

stabilization must be used:

Method 1. - Refer to Illustration 1.A parent panel run

must have a minimum of two return panels extended

in opposing directions on each side of the parent run.

Notes: A single return panel (48" minimum length)

may be used with a Non-Rail Based Off-

Modular connector.The panel must extend at

least 22" from one side of the parent run.

Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

Method 2. - Refer to Illustration 2.A parent panel run

must be a minimum of 48" and a maximum of 12 feet,

and must have at least two return panels totaling at

least 58% of the length of the parent run extended in

one direction.The minimum length of a return

panel(s) should total 60".

Note: Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

X plus Y must total the greater of:

(A) 58% of the parent run length, or

(B) 60"

Z must be no greater than 30"

Y

Z

48" minimum

30" maximum

22" minimum

Illustration 3

• Stack-on frames can be installed on top of any

structural panel frames.

• A maximum of three stack-on frames, totaling no

more than 52.5", can be added to a base panel

frame to a maximum height of 110".

• 15" and 30" stack-on frames should be added to

35", 50", and 65" base frames to maintain hang

slot modularity.

• 22.5" stack-on frames should be added to 42.5"

and 57.5" base frames to maintain hang slot

modularity.

• A 15" stack-on frame can be used on top of a

22.5" stack-on frame with no loss of modularity

of hang slots.

PANEL HEIGHT LIMITATIONS (refer to Illustration 3):

35

15

15

15

42.5

22.5

15

15

50

15

15

15

57.5

22.5

15

15

65

15

15

15

X

12' maximum

48" minimum

12' maximum

48" minimum

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

22.5”

571.5 mm

22.5”

571.5 mm

65”

1651 mm

57.5”

1460.5 mm

50”

1270 mm

42.5”

1079.5 mm

35”

889 mm

343-2152G

PAGE 1 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 1

Illustration 2

STRAIGHT PANEL GUIDELINES:

Definitions:

Parent Panel Run - Panels (or a single panel)

configured in a straight line intended to divide space.

It is usually longer than the panels used to stabilize it.

Return Panels - Panels attached to a parent run for

the purpose of stabilizing it.Return panels may also

have the effect of dividing space.

FOR ADEQUATE STABILITY of the Allsteel Stride

freestanding wall partitions, one of two methods of

stabilization must be used:

Method 1. - Refer to Illustration 1.A parent panel run

must have a minimum of two return panels extended

in opposing directions on each side of the parent run.

Notes: A single return panel (48" minimum length)

may be used with a Non-Rail Based Off-

Modular connector.The panel must extend at

least 22" from one side of the parent run.

Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

Method 2. - Refer to Illustration 2.A parent panel run

must be a minimum of 48" and a maximum of 12 feet,

and must have at least two return panels totaling at

least 58% of the length of the parent run extended in

one direction.The minimum length of a return

panel(s) should total 60".

Note: Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

X plus Y must total the greater of:

(A) 58% of the parent run length, or

(B) 60"

Z must be no greater than 30"

Y

Z

48" minimum

30" maximum

22" minimum

Illustration 3

• Stack-on frames can be installed on top of any

structural panel frames.

• A maximum of three stack-on frames, totaling no

more than 52.5", can be added to a base panel

frame to a maximum height of 110".

• 15" and 30" stack-on frames should be added to

35", 50", and 65" base frames to maintain hang

slot modularity.

• 22.5" stack-on frames should be added to 42.5"

and 57.5" base frames to maintain hang slot

modularity.

• A 15" stack-on frame can be used on top of a

22.5" stack-on frame with no loss of modularity

of hang slots.

PANEL HEIGHT LIMITATIONS (refer to Illustration 3):

35

15

15

15

42.5

22.5

15

15

50

15

15

15

57.5

22.5

15

15

65

15

15

15

X

12' maximum

48" minimum

12' maximum

48" minimum

343-2152G

PAGE 1 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 1

Illustration 2

STRAIGHT PANEL GUIDELINES:

Definitions:

Parent Panel Run - Panels (or a single panel)

configured in a straight line intended to divide space.

It is usually longer than the panels used to stabilize it.

Return Panels - Panels attached to a parent run for

the purpose of stabilizing it.Return panels may also

have the effect of dividing space.

FOR ADEQUATE STABILITY of the Allsteel Stride

freestanding wall partitions, one of two methods of

stabilization must be used:

Method 1. - Refer to Illustration 1.A parent panel run

must have a minimum of two return panels extended

in opposing directions on each side of the parent run.

Notes: A single return panel (48" minimum length)

may be used with a Non-Rail Based Off-

Modular connector.The panel must extend at

least 22" from one side of the parent run.

Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

Method 2. - Refer to Illustration 2.A parent panel run

must be a minimum of 48" and a maximum of 12 feet,

and must have at least two return panels totaling at

least 58% of the length of the parent run extended in

one direction.The minimum length of a return

panel(s) should total 60".

Note: Return panels must be no more than 30"

lower than the maximum height of the parent

panel run.

X plus Y must total the greater of:

(A) 58% of the parent run length, or

(B) 60"

Z must be no greater than 30"

Y

Z

48" minimum

30" maximum

22" minimum

Illustration 3

• Stack-on frames can be installed on top of any

structural panel frames.

• A maximum of three stack-on frames, totaling no

more than 52.5", can be added to a base panel

frame to a maximum height of 110".

• 15" and 30" stack-on frames should be added to

35", 50", and 65" base frames to maintain hang

slot modularity.

• 22.5" stack-on frames should be added to 42.5"

and 57.5" base frames to maintain hang slot

modularity.

• A 15" stack-on frame can be used on top of a

22.5" stack-on frame with no loss of modularity

of hang slots.

PANEL HEIGHT LIMITATIONS (refer to Illustration 3):

35

15

15

15

42.5

22.5

15

15

50

15

15

15

57.5

22.5

15

15

65

15

15

15

X

12' maximum

48" minimum

12' maximum

48" minimum

Straight Panel Guidelines:

Denitions:

Parent Panel Run - Panels (or a single panel) congured in

a straight line intended to divide space. It is usually longer

than the panels used to stabilize it.

Return Panels - Panels attached to a parent run for the

purpose of stabilizing it. Return panels may also have the

effect of dividing space.

FOR ADEQUATE STABILITY of the Allsteel Stride

freestanding wall partitions, one of two methods of

stabilization must be used:

Method 1. - Refer to Illustration 1. A parent panel run must

be a minimum of 48” (1219.2 mm) , a maximum of 12 feet,

(3.657 meters) and must have a minimum of two return

panels (totaling 20% of the length of the parent run) extended

in opposing directions on each side of the parent run.

Note - A single return panel (48” (1219.2 mm) minimum

length) may be used with Non-Rail Based Off-Modular

connector. The panel must extend at least 22” (558.8

mm) from one side of the parent run.

Return panels must be no more than 30” (762 mm)

lower than the maximum height of the parent panel

run.

Method 2. - Refer to Illustration 2. A parent panel run must

be a minimum of 48” (1219.2 mm), a maximum of 12 feet,

(3.657 meters) and must have at least two return panels

totaling at least 58% of the length of the parent run extended

in one direction. The minimum length of a return panel(s)

should total 60” (1524 mm).

Note - Return panels must be no more than 30” (762 mm)

lower than the maximum height of the parent panel

run.

Panel height limitations (refer to Illustration 3):

Stack-on frames can be installed on top of any

structural panel frames.

A maximum of three stack-on frames, totaling no

more than 52.5” (1333.5 mm), can be added to a base panel

frame to a maximum height of 110” (2794 mm).

15” (381 mm) and 30” (762 mm) stack-on frames should be

added to 35” (889 mm), 50”(1270 mm), and 65” (1651 mm)

base frames to maintain hang slot modularity

22.5” (571.5 mm) stack-on frames should be added to 42.5”

(1079.5 mm) and 57.5” (1460.5 mm) base frames to

maintain hang slot modularity

A 15” (381 mm) stack-on frame can be used on top of a

22.5” (571.5 mm) stack-on frame with no loss of modularity

of hang slots

Illustration 1.

Illustration 2.

Illustration 3.

30” (762 mm)

Maximum

48” (1219.2 mm)

Minumum

144” (3657.6 mm) Maximum

48” (1219.2 mm) Minimum

144” (3657.6 mm) Maximum

48” (1219.2 mm) Minimum

X plus Y must total the greater of:

(A) 58% of the parent run length or

(B) 60” (1524 mm)

(Z) must be no greater than 30” (762 mm)

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

15”

381 mm

24” (609.6mm)

Minimum

Stride Installation Packet

Page 1 of 903430215200 J

(09/19)

343-2152G

PAGE 2 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 4

Illustration 5

STACKING TO DOOR HEIGHT

Refer to Illustration 5.To stack to the 87.5"

door height, some loss of hang slot

modularity will occur.

STACKING LIMITATIONS

Stack-on frames do not have a hang slot

at the bottom of the vertical tube.

Due to this absence, hanging

components that utilize multiple,

consecutive hang slots cannot span the

joint of a base frame and a stack-on

frame or the joint of two stack-on

frames.

If a 22.5" stack-on frame is used on top

of a 35", 50", or 65" base frame, or on

top of a 15" or 30" stack-on frame, a

shift will occur in the overall height of the

hang slots.This will result in a height

variation of adjacent hanging

components.

No hanging components can span the

joint of a base frame and a stack-on

frame or the joint of two stack-on frames

if a 22.5" stack-on frame is used on top

of a 35", 50", or 65" base frame or a 15"

or 30" stack-on frame.

15

35

22.5

35

22.5

65

22.5

15

50

343-2152G

PAGE 2 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 4

Illustration 5

STACKING TO DOOR HEIGHT

Refer to Illustration 5.To stack to the 87.5"

door height, some loss of hang slot

modularity will occur.

STACKING LIMITATIONS

Stack-on frames do not have a hang slot

at the bottom of the vertical tube.

Due to this absence, hanging

components that utilize multiple,

consecutive hang slots cannot span the

joint of a base frame and a stack-on

frame or the joint of two stack-on

frames.

If a 22.5" stack-on frame is used on top

of a 35", 50", or 65" base frame, or on

top of a 15" or 30" stack-on frame, a

shift will occur in the overall height of the

hang slots.This will result in a height

variation of adjacent hanging

components.

No hanging components can span the

joint of a base frame and a stack-on

frame or the joint of two stack-on frames

if a 22.5" stack-on frame is used on top

of a 35", 50", or 65" base frame or a 15"

or 30" stack-on frame.

15

35

22.5

35

22.5

65

22.5

15

50

22.5”

571.5 mm

65”

1651 mm 50”

1270 mm

35”

889 mm

35”

889 mm

22.5”

571.5 mm

22.5”

571.5 mm

STACKING LIMITATIONS:

Stack-on frames do not have a hang slot at

the bottom of the vertical tube.

Due to this absence, hanging components

that utilize multiple, consecutive hang

slots cannot span the joint of a base

frame and a stack-on frame or the joint of

two stack-on frames.

If a 22 5” (571.5 mm) stack-on frame is

used on top of a 35” (889 mm), 50”(1270

mm), or 65” (1651 mm) base frame, or

on top of a 15” (381 mm) or 30” (762 mm)

stack-on frame, a shift will occur in the

overall height of the hang slots. This will

result in a height variation of adjacent

hanging components.

No hanging components can span the

joint of a base frame and a stack-on

frame or the joint of two stack-on frames

if a 22 5” (571.5 mm) stack-on frame is

used on top of a 35” (889 mm), 50”(1270

mm), or 65” (1651 mm) base frame or a 15”

(381 mm) or 30” (762 mm) stack-on frame.

STACKING TO DOOR HEIGHT:

Refer to Illustration 5 to stack to the 87.5”

(2222.5 mm) door height, some loss of hang

slot modularity will occur

Illustration 4.

Illustration 5.

15”

381 mm

15”

381 mm

Stride Installation Packet

Page 2 of 90

3430215200 J

(09/19)

PAGE 3 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 7

Return panels

Overhead

storage unit

Illustration 6

Return panels

Overhead

storage unit

Refer to Illustration 7.When a parent run is

supported with return panels on each side of

overhead storage units, a maximum of 5 units

can be suspended from each side of the parent

panel.

Refer to Illustration 6.In a panel run, only two

overhead storage cabinets or open storage

shelves are recommended per side, per panel.If

using a non-rail based off-modular panel

connector kit at one or both ends, do not

suspend more than one overhead storage unit

per side, per panel of the parent panel run.

When overhead storage units are suspended from

stack-on frames, the following guidelines must be

followed:

• Whenastorageunitissuspendedfroma

stack-on frame, all parent run panels and at least

the first panel of each return panel run must be

the same height as the supporting stack-on

panel, using base frames or a combination of

base frames and stack-on frames.

• Amaximumoftwooverheadstorageunits

should be suspended from each side of stack-on

frames on any given panel.

OVERHEAD STORAGE GUIDELINES:

Page 3 of 903430215200 J

(09/19)

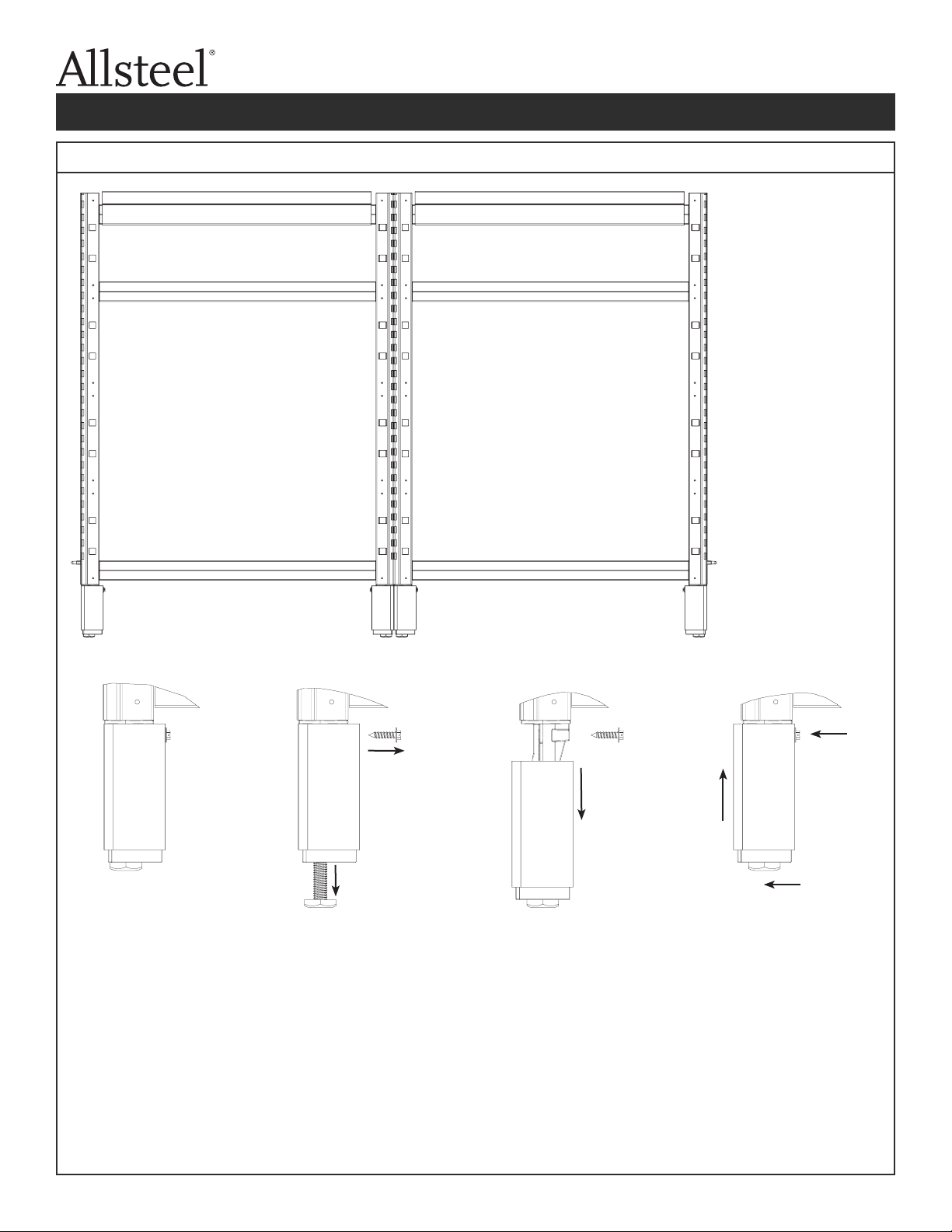

PAGE 4 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

WARNING

Illustration 8. Frame-To-Frame Connection (attachment screws provided with panel frames)

Detail 8A. Top View

Step 1 - Place frames so that leveling blocks nest together.

To insure that the two panels line up, adjust the

leveling glides on the bottom of the panels.

Note: Refer to Detail 8A.Top View for alignment of

leveling blocks.

Step 2 - Install attachment screws through larger hole in one frame and into the smaller

mating hole of adjacent frame.Fully tighten screws.Start by installing attachment

screw through the top location in the frame and work down alternating left to right.

Total Number of Screws

Required for Panel Frames

Panel Height

35"

42.5"

50"

57.5"

2

3

3

4

Screws

65" 4

IMPORTANT - For proper fit all

panels must be

level.

Failure to install product as instructed,

use of hardware other than that which

is provided with product, or failure to

comply with instructions can result in

product failure, personal injury, or

property damage.

NOTE: Start with the lower

hole at the top position,

and alternate left and

right from there down.

Refer to Pages 1-3 for

Installation Guidelines

Right

Right

Left

Left

Total Number of Screws

Required for Panel Frames

Panel Height Screws

35” (889 mm)

42.5” (1079.5 mm)

50” (1270 mm)

57.5” (1460.5 mm)

65” (1651 mm)

2

3

3

4

4

Page 4 of 90

3430215200 J

(09/19)

PAGE 5 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 9. Stack-On Frame Installation

IMPORTANT: Tiles must be removed from stack-on

frame and base panel frame prior to

stack-on frame installation.

Step 3 - Install screws through base panel

and into attachment bracket (two

.75" screws if end of run condition,

one .75" and one 2.5" if inline

condition).

Step 4 - Position stack-on frame onto

attachment brackets.

Step 2 - Insert attachment brackets into base

panel (each side).Note bracket

orientation.

Step 1 - Remove top cap, top cap retainers, and

center clip block from base panel frame

and install on stack-on frame.Refer to

Illustration 34 for top cap retainer

removal.

IMPORTANT: .75" screws in Steps 3 and 5 must be

replaced by 2.5" screws for panel

connections if frames attached in an inline

condition (see Illustration 8 for guidelines).

Attachment

Bracket

Base Panel Frame

Stack-On Frame

Step 5 - Install screws through stack-on frame and

into attachment bracket (two .75" screws if

end of run condition, one .75" and one 2.5" if

inline condition).

Page 5 of 903430215200 J

(09/19)

PAGE 6 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 10. Frame-To-Frame Connection at 90°, “T”, “X” and

Extended Straight Panel Junctures (common height)

Step 1 - Determine the configuration of the panels at the connector juncture and ensure that the connector block for

that juncture has the correct number of spacers.The side that has the outdent will always mate to a frame.

Any additional frames mating to the connector will need a spacer added to the connector block.

90° Connector “S” Connector

(Extended Straight)

“T” Connector “X” Connector

Outdent

SpacerSpacer

Spacers attached

only on sides that

mate to frames

This side always mates to a frame.

No spacer necessary.

Page 6 of 90

3430215200 J

(09/19)

PAGE 7 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 10a. Frame-To-Frame Connection at 90°, “T”, “X” and Extended

Straight Panel Junctures (common height)

Total Number of Connector

Blocks Required for Panel Frames

Panel Height

35"

42.5"

50"

57.5"

65"

2

3

3

3

4

Blocks

Step 2 - Attach the connector blocks to panel frames with one screw per block, per panel.Start on the left hole

of the lowest position on the panel frame.Refer to the table below for the correct number of connector

blocks per connector juncture.Evenly space the remaining connector blocks along the frame making

sure to place one at the highest position on the panel.Determine whether the left or right hole should

be used at each connector block position with the following rules:

- Where full data space is needed near a connector block, use the left hole at that connector position.

- 2 blocks: Use the left hole for both blocks

- 3 blocks: Use the left hole for two blocks and the right hole for one.

- 4 blocks: Use the left hole for two blocks and the right hole for two blocks.

Full Data

Opening

Right

Right

Left

Left

Partial Data

Opening

Section view of 65"H

panel frame with four

connector blocks.

Total Number of Connector Blocks

Required for Panel Frames

Panel Height Screws

35” (889 mm)

42.5” (1079.5 mm)

50” (1270 mm)

57.5” (1460.5 mm)

65” (1651 mm)

2

3

3

3

4

Section view of 65”

(1651 mm) panel

frame with four

connector blocks

Page 7 of 903430215200 J

(09/19)

3430215200 J

PAGE 8 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 11. Installing Connector Blocks with Stack-On Frames

Step 1 - Refer to Illustration 10 for the correct connector block configuration and orientation

Step 2 - Ensure that there is one connector block at the top and bottom of each stack-on frame, and at the

top of each base frame.

Step 3 - Refer to Step 2 of Illustration 10a to ensure that all required connector blocks have been installed.

Connector

Block for

bottom of 15"

Stack-On

Frame

50" Base Frame

15" Stack-On

Frame

Connector Block

for top of both

Stack-On Frames

30" Stack-On

Frame

Connector Block

for bottom of 30"

Stack-On Frame

Connector Block

for top of 65"

Base Frame

65" Base Frame

30” (762 mm)

Stack-On Frame

15” (381 mm)

Stack-On Frame

Connector Block

for bottom of

15” (381 mm)

Stack-On Frame

Connector Block for

top of 65” (1651 mm)

Base Frame

Connector Block

for bottom of

30” (762 mm)

Stack-OnFrame

50” (1270 mm) Base Frame 65” (1651 mm) Base Frame

Page 8 of 90

(09/19)

343-2152G

PAGE 9 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 12. Light Block Installation

Step 1 - If light block is being used in a variable

height application, cut the light block to

the same height as the shortest panel it

will be adjacent to.

“L” Light Block

Step 2 - Once the connector blocks are secured to

the frames, press the light block into the

connector block.The top of the light

block should be flush with the top of the

panel frame vertical.

“X” Light Block

“T” Light Block

Illustration 12. Light Block Installation

Stride Installation Packet

Page 9 of 903430215200 J

(09/19)

343-2152G

PAGE 10 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 13. Frame-To-Frame Variable Height Connection

Step 1 - In variable height applications, place connector blocks on shortest base panel, according to the table in Illustration

10a.

Step 2 - Place 1 connector block for each 7.5" level change and 2 connector blocks for each 15" or greater level change

above top of the shortest base panel.A level change is defined as any change in height from the top of one

frame, base frame or stack-on frame, to the top of the next highest frame, until there are less than 2 frames

higher than the last level.

Step 3 - Snap variable height trim onto connector blocks and frames as shown in illustration 32.

57.5" high panel

57.4" high light block

7

.5" high 90°

filler trim

50" high panel

7.5" high end trim

90° top cap transition

piece

65" high panel

35" high panel

End Trim

Transition Piece

15" high flat filler trim

50" high

light block

35" high light block

“X”, “T”, and 90°

configured connector

blocks

Step 1 - In variable height applications, place connector blocks on shortest base panel, according to the table in

Illustration 10a.

Step 2 - Place 1 connector block for each 7.5” (190.5 mm) level change and 2 connector blocks for each 15” (381 mm)

or greater level change above top of the shortest base panel A level change is dened as any change in height

from the top of one frame, base frame or stack-on frame, to the top of the next highest frame, until there are

less than 2 frames higher than the last level.

Step 3 - Snap variable height trim onto connector blocks and frames as shown in illustration 30.

Illustration 13. Frame-to-Frame Variable Height Connection

57.5” (1460.5 mm)

high panel

57.4” (1467.9 mm)

light block

65” (1651 mm)

high panel

7.5” (190.5 mm)

high 90° ller trim

7.5” (190.5 mm)

high end trim

15” (381 mm)

high at ller trim

35” (889 mm)

high panel

35” (889 mm) high

light block

50” (1270 mm)

high light block

50” (1270 mm)

high panel

Stride Installation Packet

Page 10 of 90

3430215200 J

(09/19)

PAGE 11 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 14. Permanent Wall Mount Connection

Step 1 - Remove screw to take leveling block off of the side of panel that will be

affixed to the wall mount.

Step 2 - Ensure that the wall mount is vertically plumb.

Step 3 - With top caps off, align top of wall mount to top of panel frame vertical.

Step 4 - Attach wall mount to wall using appropriate attachment hardware (wood

screws 2-1/2" minimum length) into studs, or Molly-type fastener (not

provided) into drywall, through the large diameter holes.

Step 5 - Connect panel frame to wall mount using the attachment screws included

with the panel (refer to Illustration 8 and copy the panel-to-panel

attachment method).

Wall Mount Top Cap

Trim Connector

Panel Top Cap

Panel Frame

Attachment Screw

Wall Mount

Notch identifies

top of wall mount.

Larger diameter holes

are used for fastening

wall mount to the wall.

Smaller diameter holes

are used for fastening

wall mount to the panel.

Leveling

block

Page 11 of 903430215200 J

(09/19)

3430215200 J

PAGE 12 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 15. Baserail Cover Removal

Step 1 - Insert flat blade screwdriver between Baserail cover

and bottom frame horizontal.Pivot screwdriver

upward to free Baserail cover from glide towers.

Step 2 - Repeat Step 1 on opposite end of panel frame.

Step 3 - Lift Baserail cover free of panel frame.

Page 12 of 90

(09/19)

343-2152G

PAGE 13 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 16. Footed Panel Adjustment

To adjust panel

foot for end of

run application:

Step 1 -

Extend leveler about

1" and remove

attachment screw.

A 2x4 should be

placed under the

bottom horizontal

member of the panel

frame if using a pry

bar to raise the

panel frame.Do not

pry up on the panel

foot.

Step 2 -

Lower panel foot

sleeve and cover.

Step 3 -

Shift cover and sleeve

over 1/4", and raise

back up, reattach with

screw, and retract

leveler.

NOTE: Footed

panels are shipped

ready to be installed

in an in-line

application.

3rd

1st

2nd

Step 1 - Extend leveler about

1” (25.4 mm) and

remove attachment

screw

A 2x4 should be

placed under the

bottom horizontal

member of the panel

frame if using a pry

bar to raise the panel

frame do not pry up

on the panel foot.

To adjust panel

foot for end of

run application:

Step 2 -Lower panel foot

sleeve and cover.

Step 3 - Shift cover and sleeve

over 1/4” (6.35 mm),

and raise back up,

reattach with screw,

and retract leveler

Illustration 16. Footed Panel Adjustments

Stride Installation Packet

Page 13 of 903430215200 J

(09/19)

343-2152G

PAGE 14 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 17. Low Profile Glass - Support Brackets

IMPORTANT - When spanning multiple frames, mount

support brackets to all base panels.Ensure

panels are level.

Step 1 - Remove top cap and set aside.

Top Cap

Illustration 17. Low Prole Glass - Support Brackets

Stride Installation Packet

Page 14 of 90

3430215200 J

(09/19)

343-2152G

PAGE 15 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 18. Low Profile Glass (LPG) Installation

IMPORTANT:

•Review Illustrations 19-27 to determine proper assembly based on end connection.

•Top tile on each side of base panel must be removed prior to LPG installation.

Step 1 - Remove outer vertical rib

(painted black) as

required depending on

end connection (see

Illustration 19-27 for end

conditions).

Step 4 -

Insert screw

through panel frame

into stacking bracket

in upper left location

first on both ends

(3/4" screw).

Step 2 - Remove upper panel connector screws (skip

this step at end of panel run).

Step 3 -

Insert stacking

bracket into base

panel verticals and

lower glass assembly

into place.

Step 5 - Replace panel connector screw from Step 2

into lower right hole.If no panel connector

screw is used, use the 3/4" screw from Step 4.

Outer vertical rib

Illustration 18. Low Prole Glass (LPG) Installation

Stride Installation Packet

Page 15 of 903430215200 J

(09/19)

343-2152G

PAGE 16 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 19. Low Profile Glass - In-Line Connection - LPG to Panel

Step 1 - Install LPG (see Illustration 18).

Step 2 -

Secure LPG to adjacent base panel using 2.5" frame

connector screw in an alternating pattern.Refer to

Illustration 20.

Screw locations for panel attachment - only

the locations shown can be used.

Always use upper

right location

Always use lower

left location

May use these

locations

Illustration 20. LPG Screw Hole Location Options

343-2152G

PAGE 16 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 19. Low Profile Glass - In-Line Connection - LPG to Panel

Step 1 - Install LPG (see Illustration 18).

Step 2 - Secure LPG to adjacent base panel using 2.5" frame

connector screw in an alternating pattern.Refer to

Illustration 20.

Screw locations for panel attachment - only

the locations shown can be used.

Always use upper

right location

Always use lower

left location

May use these

locations

Illustration 20. LPG Screw Hole Location Options

Step 1 - Install LPG (see Illustration 18)

Step 2 - Secure LPG to adjacent base panel using

2.5” (6.35 mm) frame connector screw in an

alternating pattern. Refer to Illustration 20.

Illustration 19. Low Prole Glass - In-Line Connection - LPG to Panel

Illustration 20. LPG Screw Hole Location Options

Stride Installation Packet

Page 16 of 90

3430215200 J

(09/19)

PAGE 17 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 21. Low Profile Glass - In-Line Connection - LPG to LPG

Step 1 - Install first LPG (see Illustration 18).

Step 2 - Remove vertical rib from each LPG.

Step 3 - Reattach both vertical ribs to the first LPG using 1.5" screw provided as shown.

Fasten screws through same holes where vertical ribs were initially attached.

Step 4 - Install second LPG, securing the stacking bracket furthest from the first LPG first.

Note: Tie bracket is required for this configuration.See Illustration 28.

Step 3

Secure the bracket opposite

the first LPG first.

Page 17 of 903430215200 J

(09/19)

3430215200 J

PAGE 18 OF 108 (8/12)

Stride Installation Packet

Stride Installation Packet

Illustration 22. Low Profile Glass - Connector Block Pre-Assembly

When LPG is used at a connector block connection, it is necessary to

pre-assemble 1 or 2 LPG vertical rib components to the connector

blocks prior to LPG installation.

IMPORTANT - See Illustrations 24-27 for number of vertical rib

components to pre-assemble.Do not install more than

two vertical ribs to the subassembly.

Step 1 - Attach required number of connector blocks to

1 vertical rib using 1.5" screws provided (same as

above).

Step 2 - Attach a second vertical rib, creating an “L”

configuration (only if second vertical rib is required).

Illustration 23. Low Profile Glass - Vertical Rib Installation

IMPORTANT - When reinstalling vertical rib, tabs should insert into groove in LPG verticals as shown

Vertical Rib

Connector

Block

Page 18 of 90

(09/19)

PAGE 19 OF 108 (8/12)

Stride Installation PacketStride Installation Packet

Illustration 24. Low Profile Glass - 1 LPG at Connector Block Connection

These instructions cover configurations with 1 LPG and 1 to 3 base panels at a connector block connection.

NOTE: If multiple base panels are already installed with connector blocks, connector blocks for LPG must be removed

prior to Step 1.

Step 1 - Remove vertical rib from one end and attach

connector blocks (see Illustration 22.)

Step 2 - Attach vertical rib subassembly to LPG reusing

screws from Step 1.

Step 4 - Secure other base

panels to connector

blocks.

Step 3 - Install LPG (see

Illustration 19).

NOTE: Tie bracket not required for

this configuration.

Page 19 of 903430215200 J

(09/19)

Table of contents

Other Allsteel Office Equipment manuals

Popular Office Equipment manuals by other brands

hushoffice

hushoffice hushtwin HUS-BX-019 Maintenance and safety manual

silen

silen Space 2 Assembly manual

Middle Atlantic Products

Middle Atlantic Products LD Series instruction sheet

SHFL

SHFL DECK MATE BLACKJACK Service manual

VITRA

VITRA Stefan Hürlemann Dancing Wall Assembly instructions

BISLEY

BISLEY Glide V2 Assembly instructions