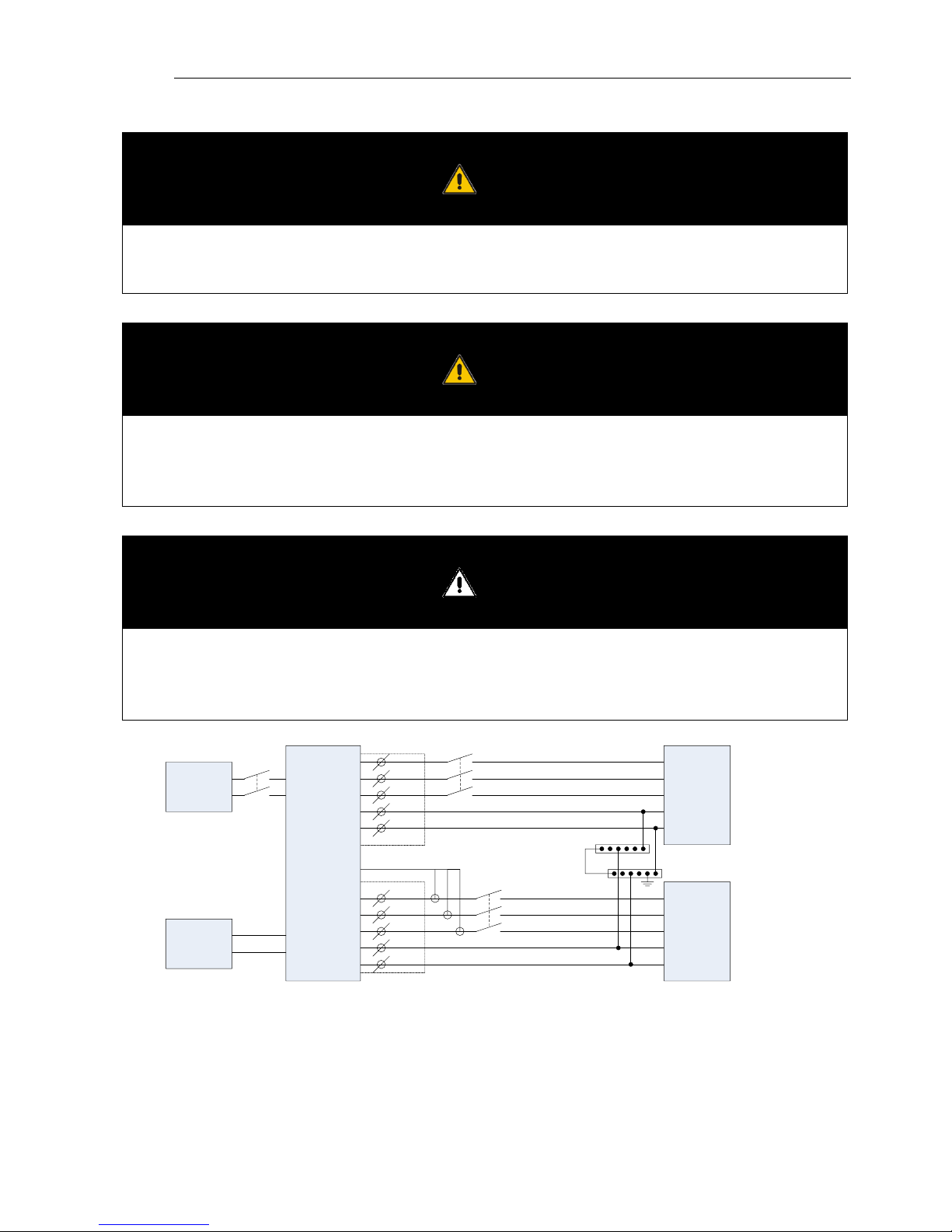

4.6.6 Wiring of terminal strips....................................................................................................................................16

4.7 Check after installation..............................................................................................................................................17

Chapter V Commissioning and Operation.................................................... 18

5.1 Operation state............................................................................................................................................................18

5.1.1 Automatic startup................................................................................................................................................19

5.2 Startup and shutdown...............................................................................................................................................19

5.2.1 Check before startup ..........................................................................................................................................19

5.2.2 Startup steps.........................................................................................................................................................20

5.2.3 Shutdown steps....................................................................................................................................................20

5.2.4 Emergency shutdown.........................................................................................................................................20

Chapter VI Operation Control Display Panel.................................................. 22

6.1 Operation instructions ..........................................................................................................................................................22

6.1.1 Main interface of monitoring startup...................................................................................................................22

6.1.2 Interface of main wiring diagram ..........................................................................................................................22

6.1.3 Login interface............................................................................................................................................................23

6.1.4 System information interface..................................................................................................................................23

6.1.5 Interface of event records........................................................................................................................................24

6.2 Setting information................................................................................................................................................................24

6.2.1 Monitoring parameter interface.............................................................................................................................24

6.2.2 System parameter interface ....................................................................................................................................25

6.2.3AC parameter interface..............................................................................................................................................25

6.2.4DC parameter interface .............................................................................................................................................26

6.2.5Parameter diagnosis interface .................................................................................................................................27

6.2.6Local strategy interface..............................................................................................................................................28

6.2.7Control state interface ...............................................................................................................................................28

6.2.8Startup and shutdown interface..............................................................................................................................29

Chapter VII Communication Mode .......................................................... 30

7.1Communication interface ......................................................................................................................................................30

7.1.1RS485 serial port .........................................................................................................................................................30

7.1.2Ethernet port................................................................................................................................................................31

7.1.3Communication with BMS ........................................................................................................................................32

7.2 Monitoring system structure ...............................................................................................................................................32

Chapter VIII Maintenane and Preservation ................................................... 34

8.1Operation environment requirements ...............................................................................................................................34

8.2Electrical and fixed connection inspection........................................................................................................................34

8.3Clearing and cleaning.............................................................................................................................................................34

Appendixes................................................................................ 35

Appendix 1: Fault information of Bi-directional Hybrid Storage Inverter.......................................................................35

Appendix 2: Quality assurance and after-sales service .......................................................................................................35

Installation Records ........................................................................ 37