0

Table of Contents

ABOUT THIS MANUAL ......................................................................................................................................1

Purpose ................................................................................................................................................1

Scope ...................................................................................................................................................1

SAFETY INSTRUCTIONS...................................................................................................................................1

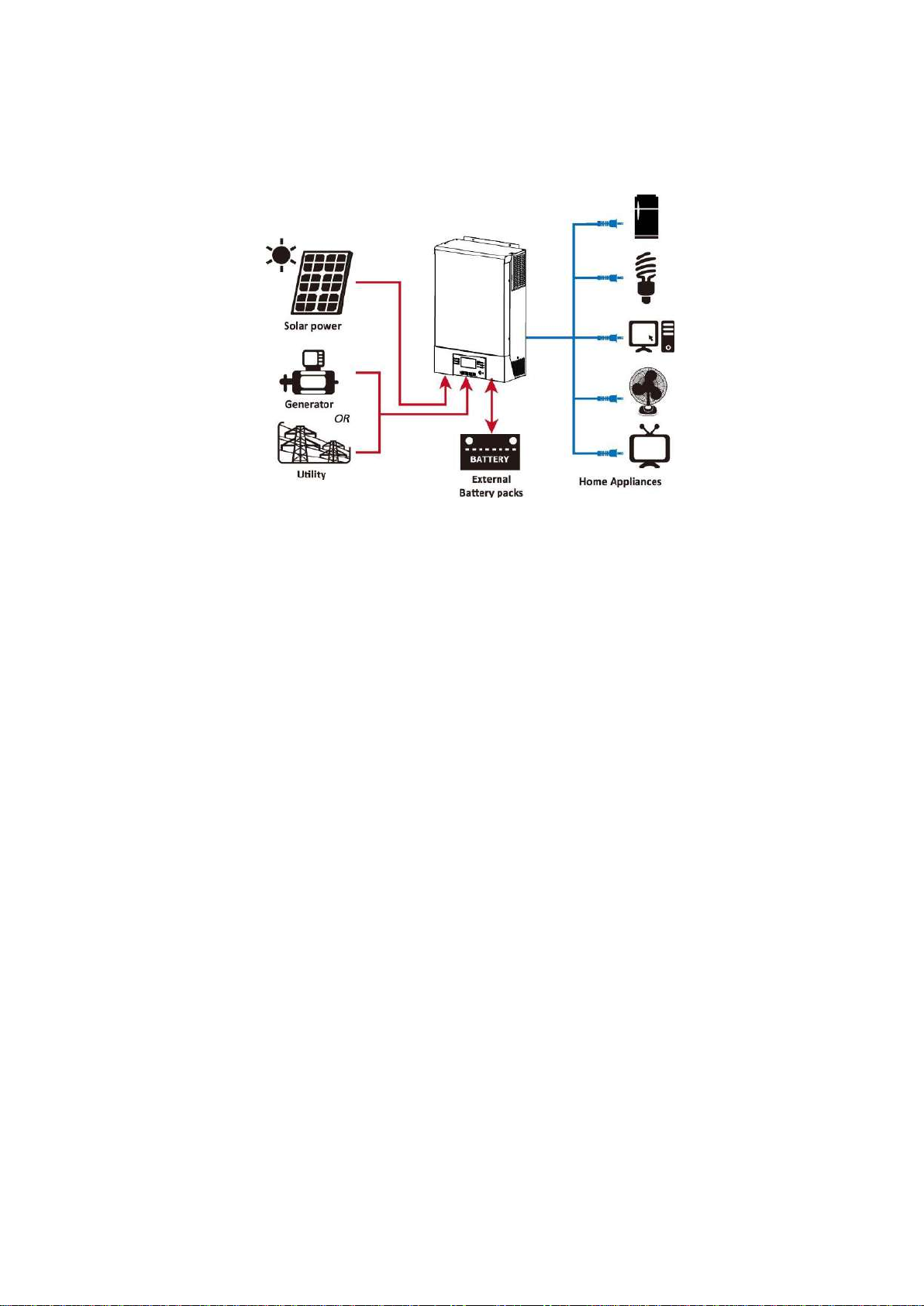

INTRODUCTION.................................................................................................................................................2

Product Overview ..................................................................................................................................3

INSTALLATION...................................................................................................................................................4

Unpacking and Inspection ......................................................................................................................4

Preparation ...........................................................................................................................................4

Mounting the Unit..................................................................................................................................4

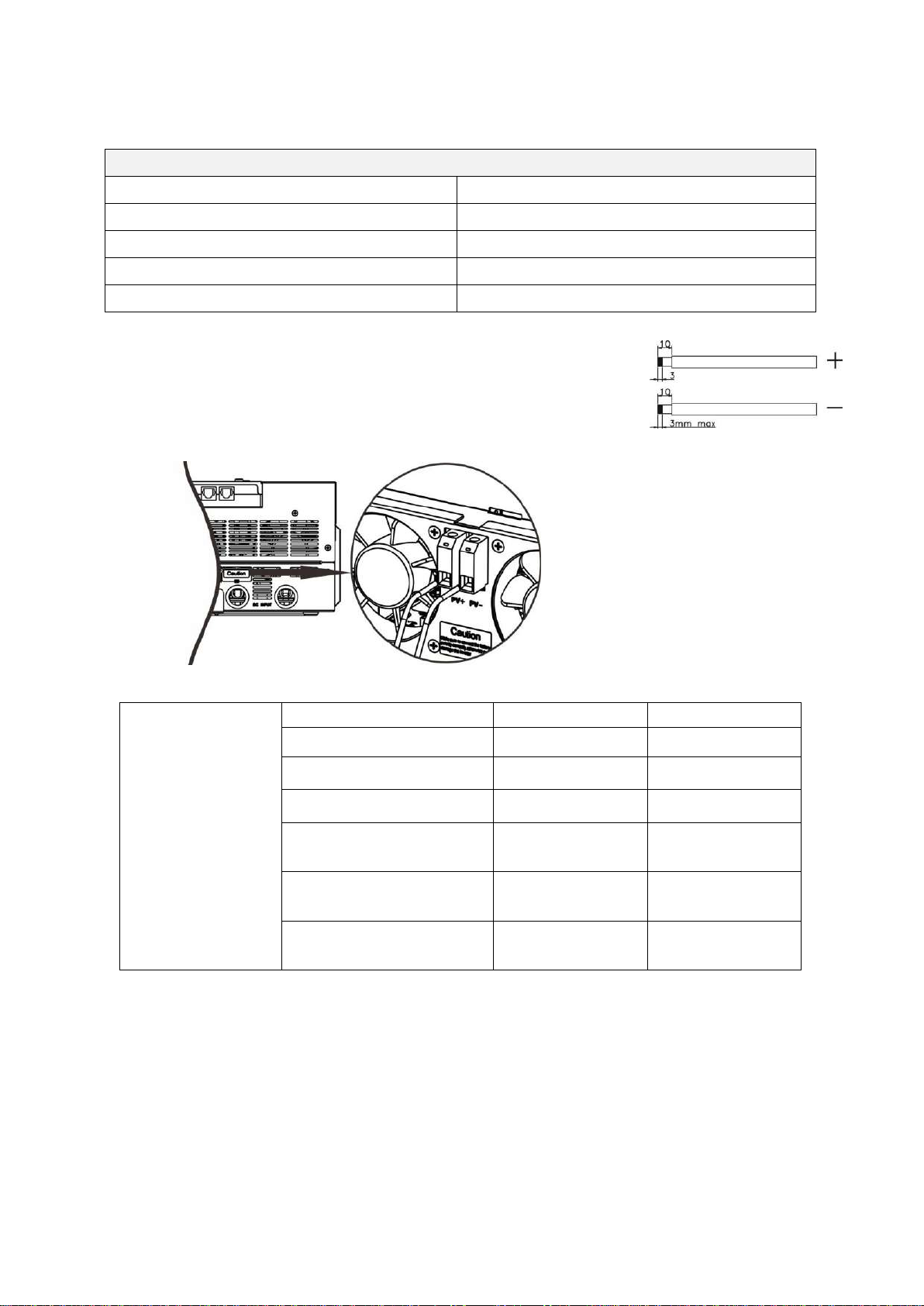

Battery Connection ................................................................................................................................5

AC Input/Output Connection ..................................................................................................................6

PV Connection.......................................................................................................................................7

Final Assembly ......................................................................................................................................9

Remote Display Panel Installation .........................................................................................................10

Communication Connection ................................................................................................................101

Dry Contact Signal...............................................................................................................................12

BMS Communication ............................................................................................................................12

OPERATION......................................................................................................................................................13

Power ON/OFF ....................................................................................................................................13

Operation and Display Panel.................................................................................................................13

LCD Display Icons................................................................................................................................14

LCD Setting.........................................................................................................................................16

Display Setting ....................................................................................................................................28

Operating Mode Description .................................................................................................................34

Faults Reference Code .........................................................................................................................36

Warning Indicator................................................................................................................................37

BATTERY EQUALIZATION ..............................................................................................................................38

SPECIFICATIONS.............................................................................................................................................40

Table 1 Line Mode Specifications ..........................................................................................................40

Table 2 Inverter Mode Specifications.....................................................................................................41

Table 3 Charge Mode Specifications ......................................................................................................42

Table 4 General Specifications ..............................................................................................................42

Table 5 Parallel Specifications ............................................................................................................. 423

TROUBLE SHOOTING.....................................................................................................................................44

Appendix I: Parallel function..........................................................................................................................45

Appendix II: BMS Communication Installation.............................................................................................62

Appendix III: Approximate Back-up Time Table ...........................................................................................68