Electric Rim Strike

AL150

01202 676262

01202 680101

Registered in England & Wales 1925537 © April 2018 IEC. All rights reserved. All dimensions are nominal and subject to tolerances

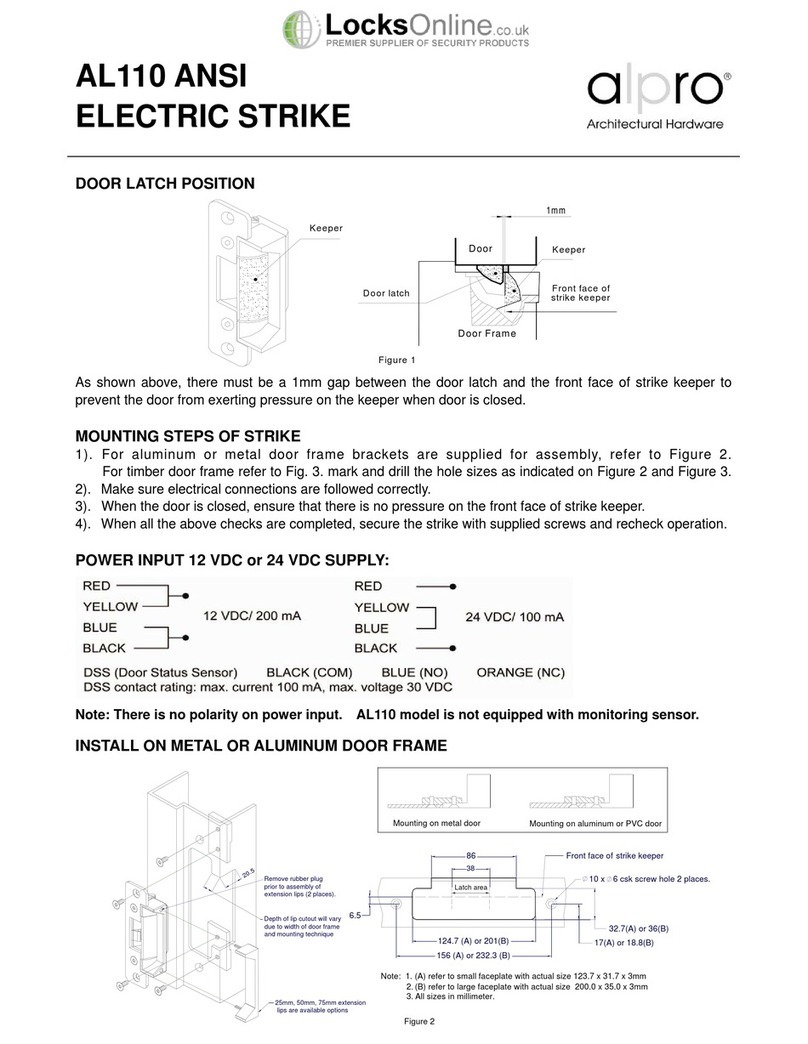

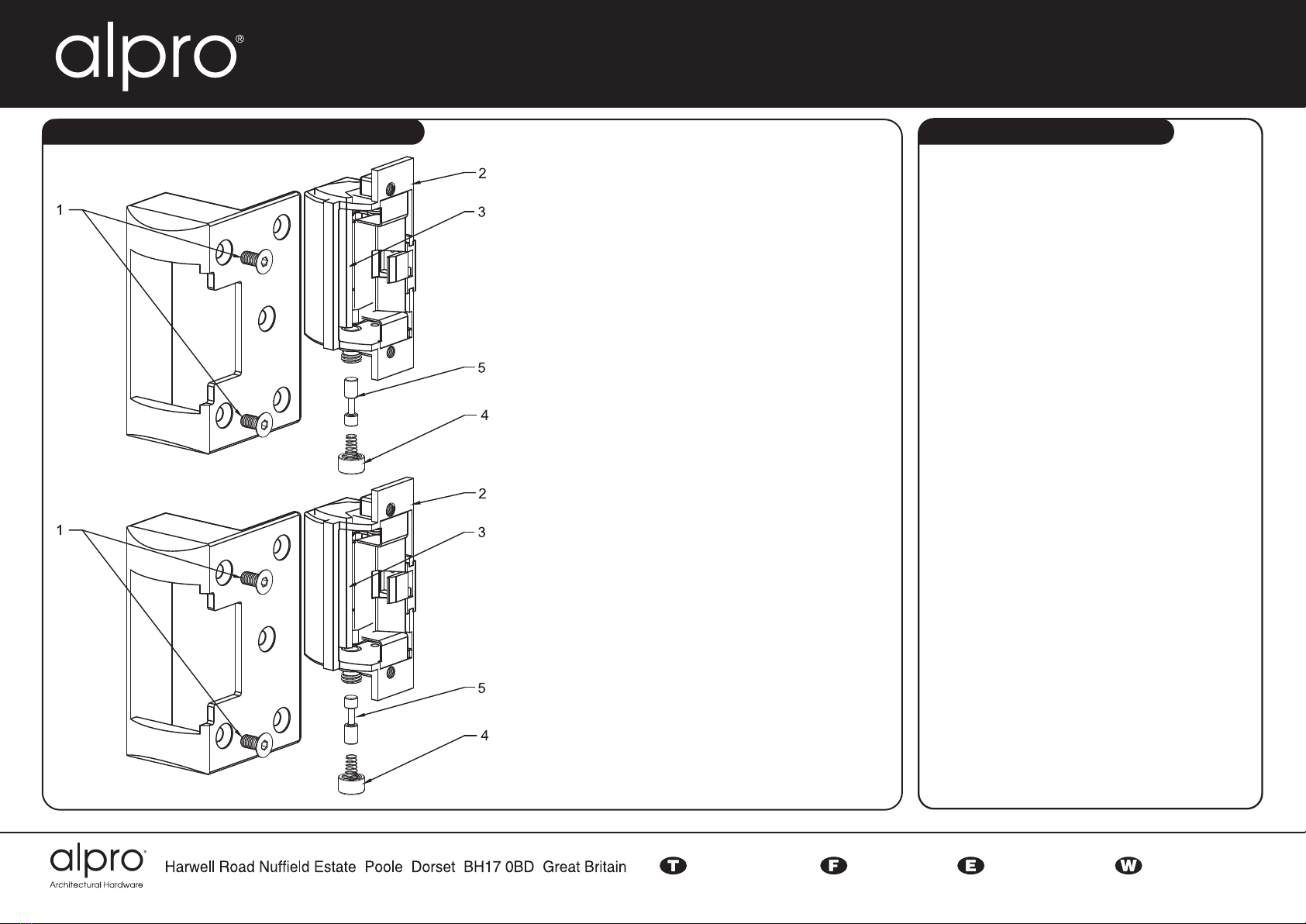

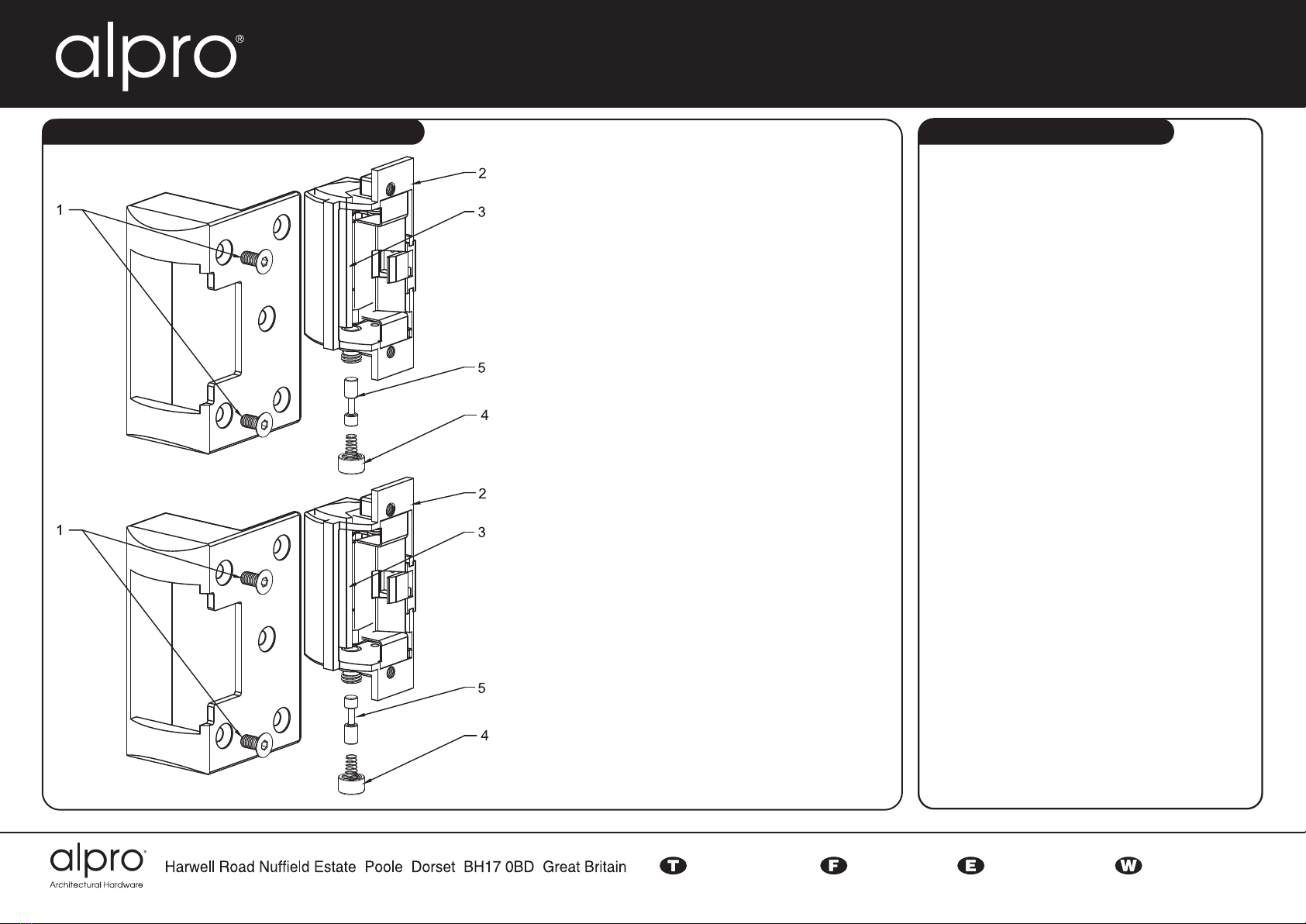

CONVERSION: POWER TO LOCK <=> POWER TO OPEN

Figure 4A

Figure 4B

WARNING:

Do not press on the keeper to release when the

spring screw is not totally secured in position, this

will cause damage to the spring barbell. When

changing function, micro switch will spring out.

Procedures to convert Power to Open (Figure

4B) to Power to Lock (Figure 4A):

Step 1: Remove the two cover plate screws.

Step 2: Remove the lock body from the cover

housing.

Step 3: Remove the spring screw from the end

part of the strike body.

Step 4: Remove the Barbell and replace in

reverse position with long part in and short

part out.

Step 5: Replace the spring screw.

Step 6: Refit the lock body into the cover housing

and screw in the two cover plate screws.

Procedures to convert Power to Lock (Figure

4A) to Power to Open (Figure 4B):

Step 1: Remove the two cover plate screws.

Step 2: Remove the lock body from the cover

housing.

Step 3: Remove the spring screw from the end

part of the strike body.

Step 4: Remove the Barbell and replace in

position with short part in and long part

out.

Step 5: Replace the spring screw.

Step 6: Refit the lock body into the cover housing

and screw in the two cover plate screws.

ELECTRIC STRIKE MAINTENANCE

Maintenance should be carried out every

6 months, or higher for heavy duty door

traffic.

Electric strikes should be fitted exactly in

accordance with the Alpro fixing

instructions, ensuring and maintaining all

relevant door gaps and clearances.

Under no circumstances use a spray

lubricant, as this type of solvent can

damage electronics. Electrical parts with

the strike need no maintenance.

If required fit a protective diode as close

to the coil as possible to protect the

system from transient peaks.

Ensure on a regular; basis the whole of the

door system is checked (lock case, door

closer, strike plate, handles etc.) to ensure

the desired level of door operation and

security is being maintained.

PLEASE NOTE:

The warranty for the strike is void if:

The strike is assembled incorrectly

Parts fitted to the strike which are not

approved Alpro Parts

The strike is incorrectly wired

There is incorrect voltage applied to the

strike

Alpro electric strikes should be installed

by suitably qualified engineers