5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-5061 Rev.9 P. 1 / 3

INSTRUCTION MANUAL

Mini-M™

PULSE ISOLATOR MODEL M2PP

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Signal conditioner (body + base socket).............................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■NONINCENDIVE APPROVAL OPTION

• This equipment is suitable for use in Class I, Div. 2,

Groups A, B, C and D or Non-Hazardous Locations only.

• WARNING! Before You Remove the Unit from Its Base

Socket or Mount It, Turn Off the Power Supply and Input

Signal for Safety.

• WARNING! – Explosion Hazard –

Substitution of Components May Impair Suitability for

Class I, Div. 2.

• WARNING! – Explosion Hazard –

Do Not Disconnect Equipment Unless Power Has Been

Switched Off or The Area is Known To Be Non-Hazardous.

• The equipment was evaluated for use in the ambient tem-

perature and relative humidity as mentioned in ‘ENVI-

RONMENT’ section.

• The input and output wiring must be in accordance with

Class I, Div. 2 wiring methods and in accordance with the

authority having jurisdiction for use in these hazardous

locations.

■CONFORMITY WITH EU DIRECTIVES

• This equipment is suitable for Pollution Degree 2, Meas-

urement Category II (output, transient voltage 1500V)

and Installation Category II (transient voltage 2500V).

Reinforced insulation (signal input or output to power in-

put: 300V) and basic insulation (signal input to output:

300V) are maintained. Prior to installation, check that

the insulation class of this unit satisfies the system re-

quirements.

• Altitude up to 2000 meters.

• The equipment must be mounted inside a panel.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to CE requirements. Failure to observe these re-

quirements may invalidate the CE conformance.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may af-

fect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure the CE conform-

ity.

• Install lightning surge protectors for those wires connect-

ed to remote locations.

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

85 – 264V AC rating: 85 – 264V, 47 – 66 Hz, approx. 3 – 5VA

24V DC rating: 24V ±10%, approx. 3W

11 – 27V DC rating: 11 – 27V, approx. 3W

110V DC rating: 85 – 150V, approx. 3W

■GENERAL PRECAUTIONS

• Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be sure that the ventilation slits are not covered with ca-

bles, etc.

■WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

• With voltage output, do not leave the output terminals

shortcircuited for a long time. The unit is designed to

endure it without breakdown, however, it may shorten ap-

propriate life duration.

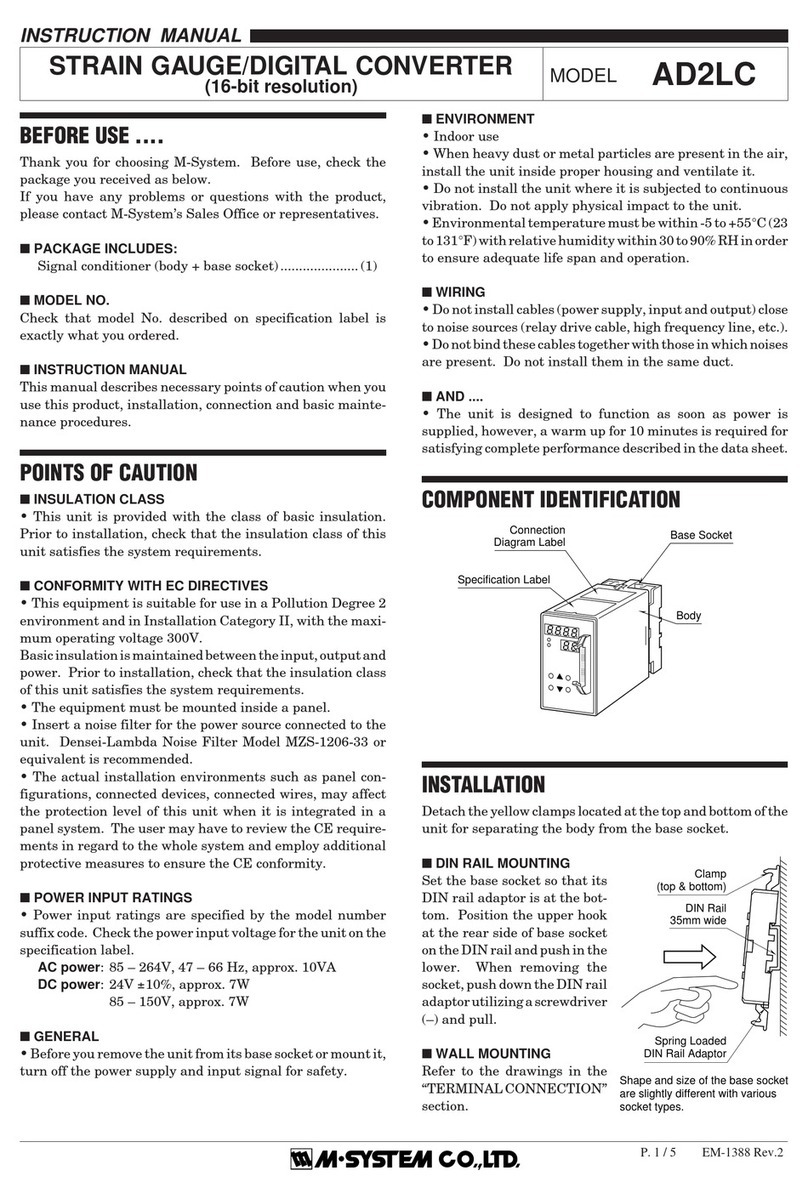

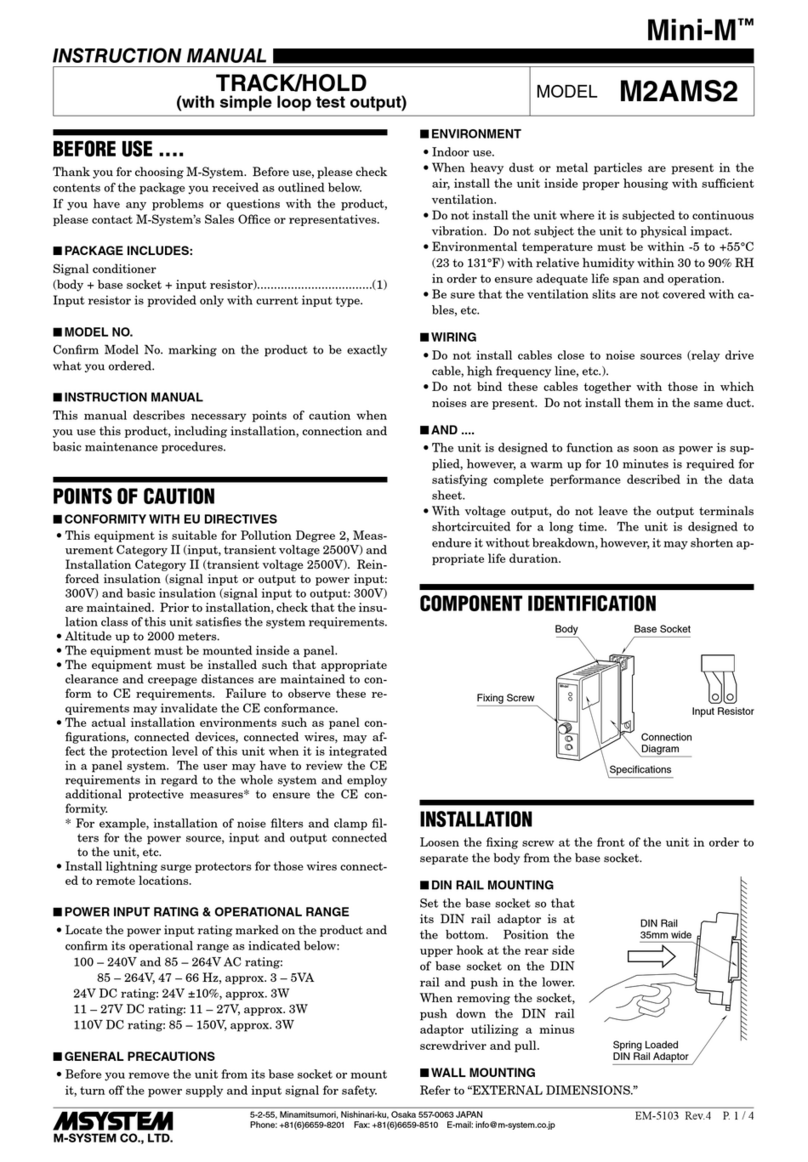

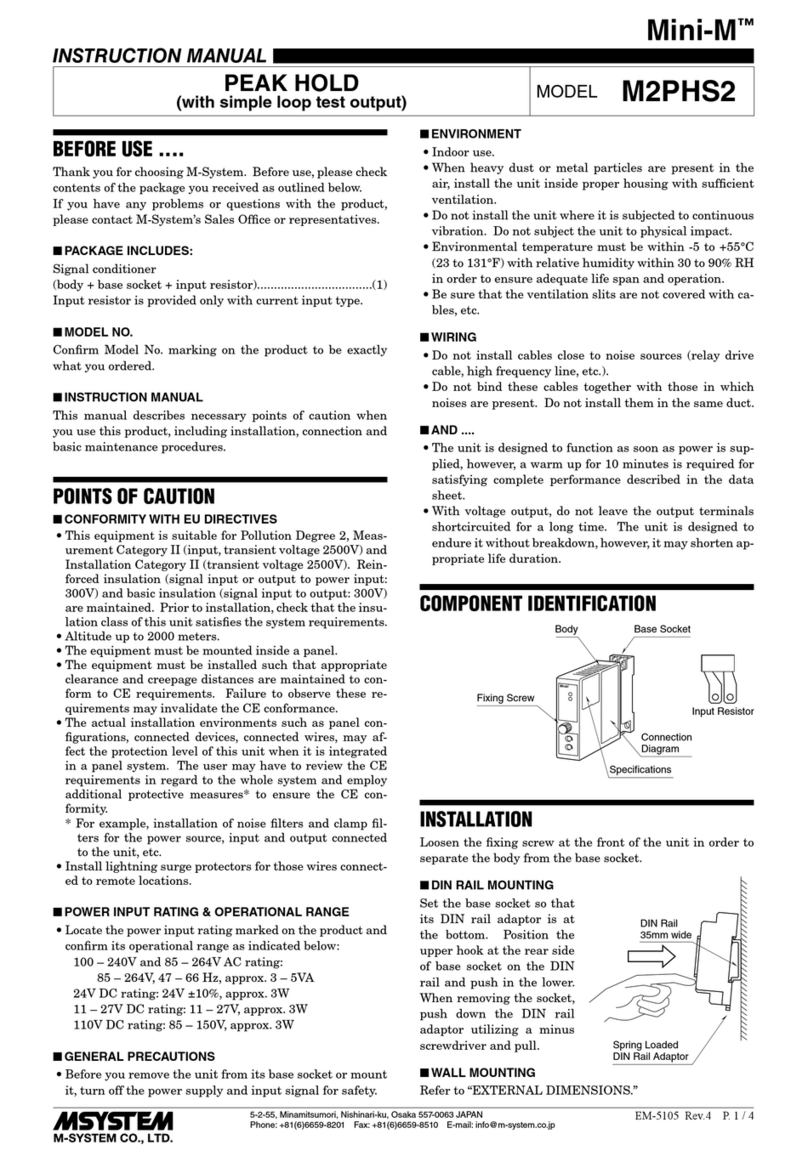

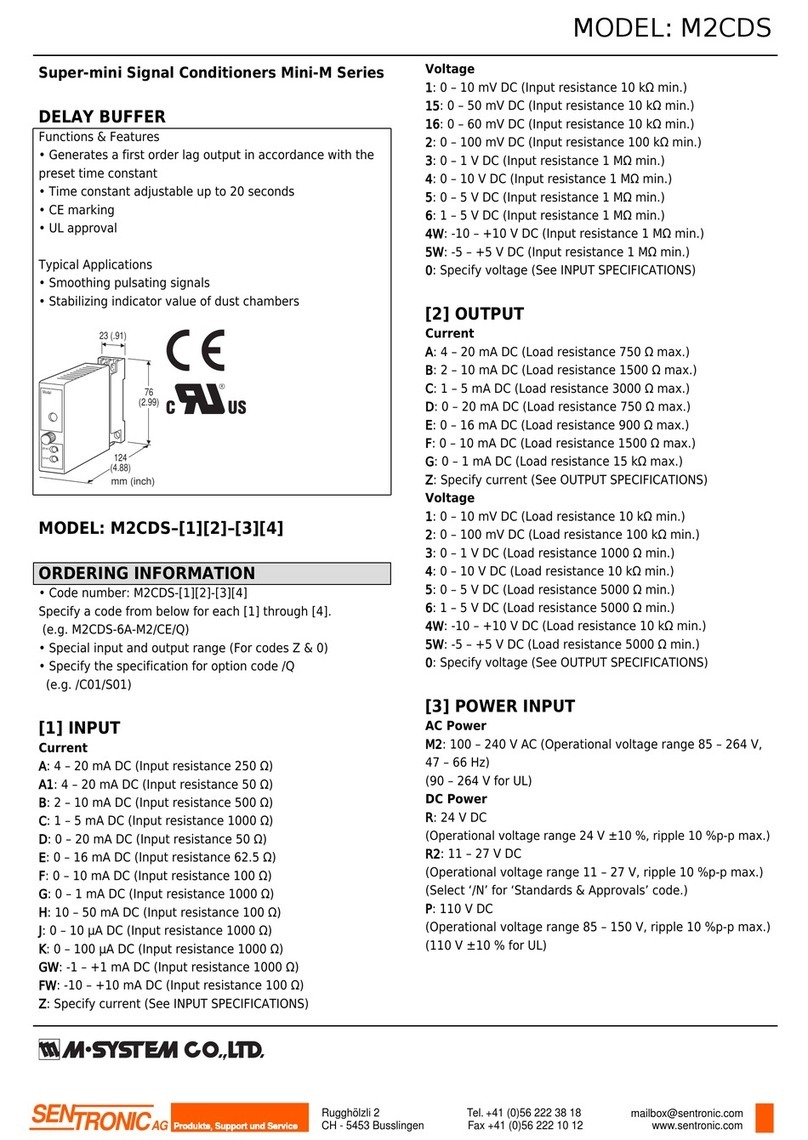

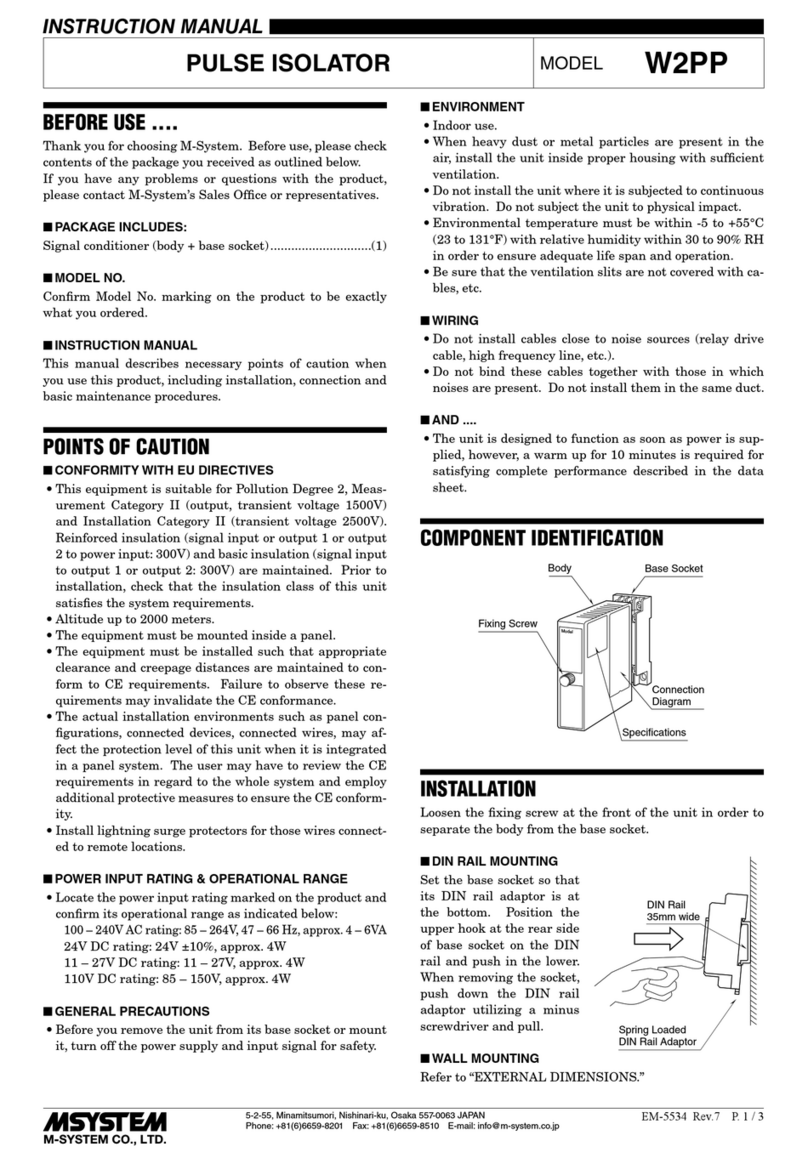

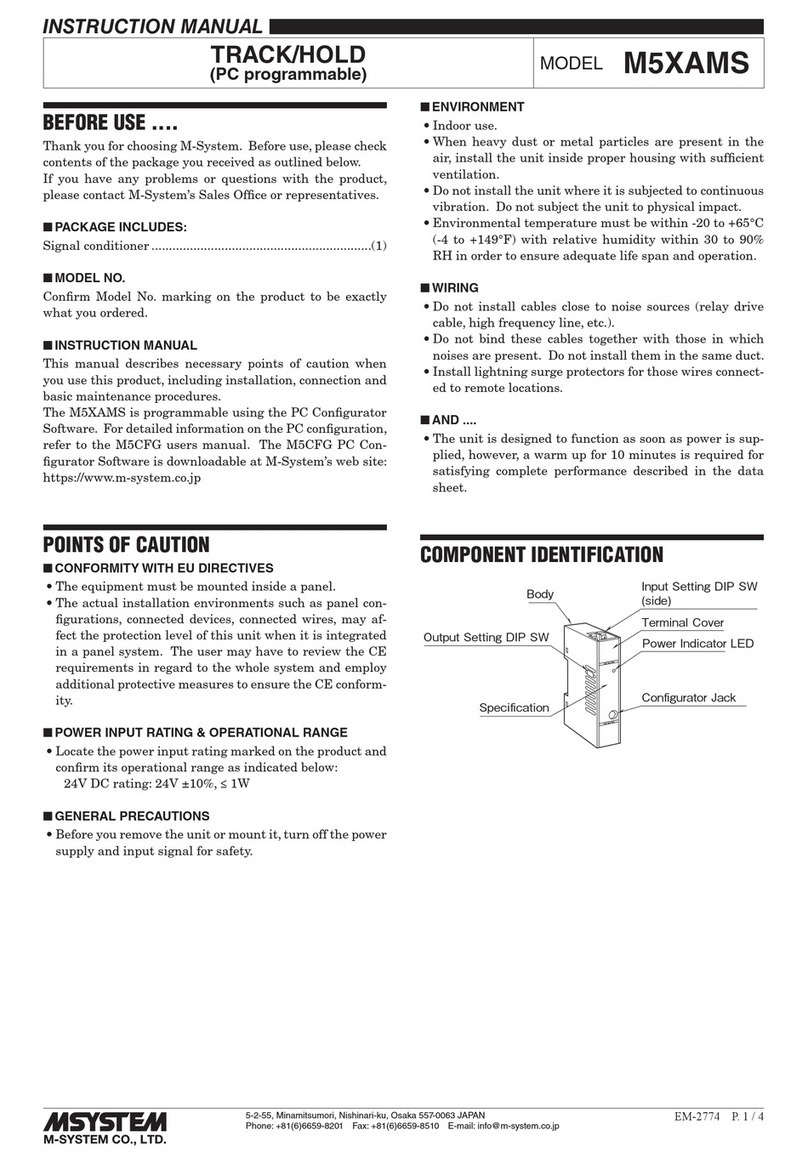

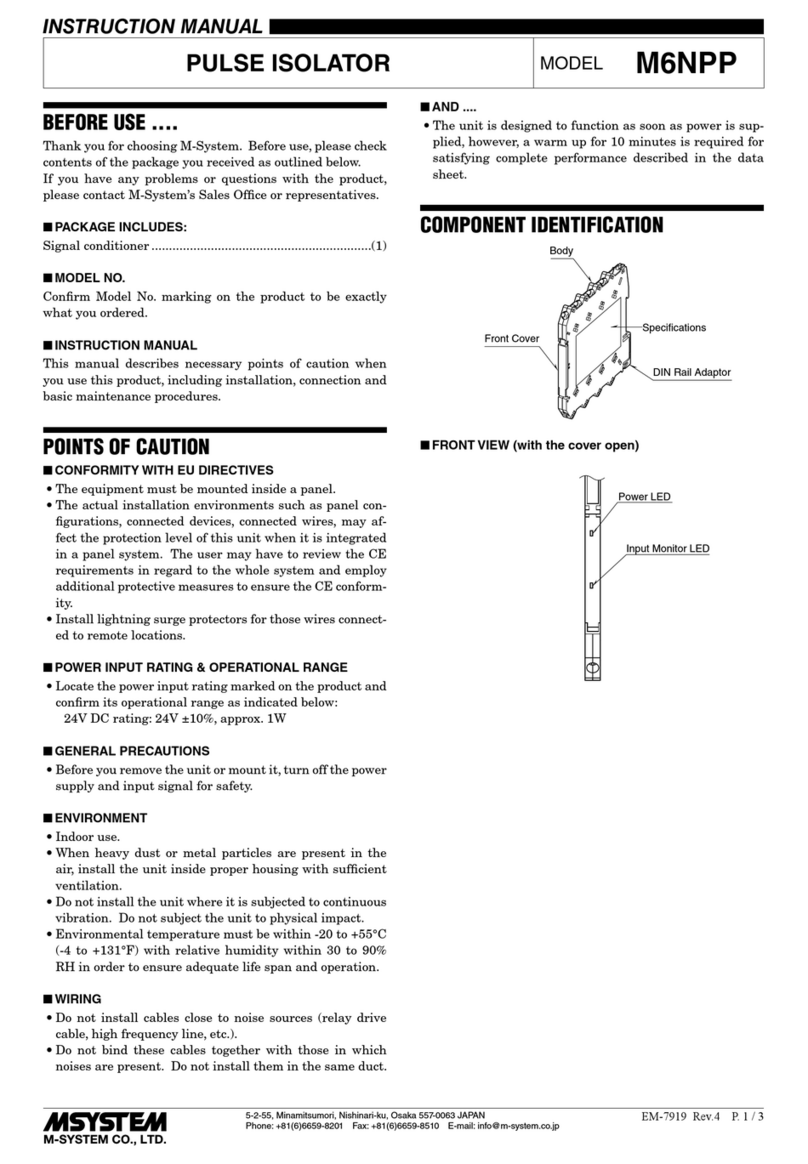

COMPONENT IDENTIFICATION

Model

Body Base Socket

Connection

Diagram

Specifications

Fixing Screw