pg. 2

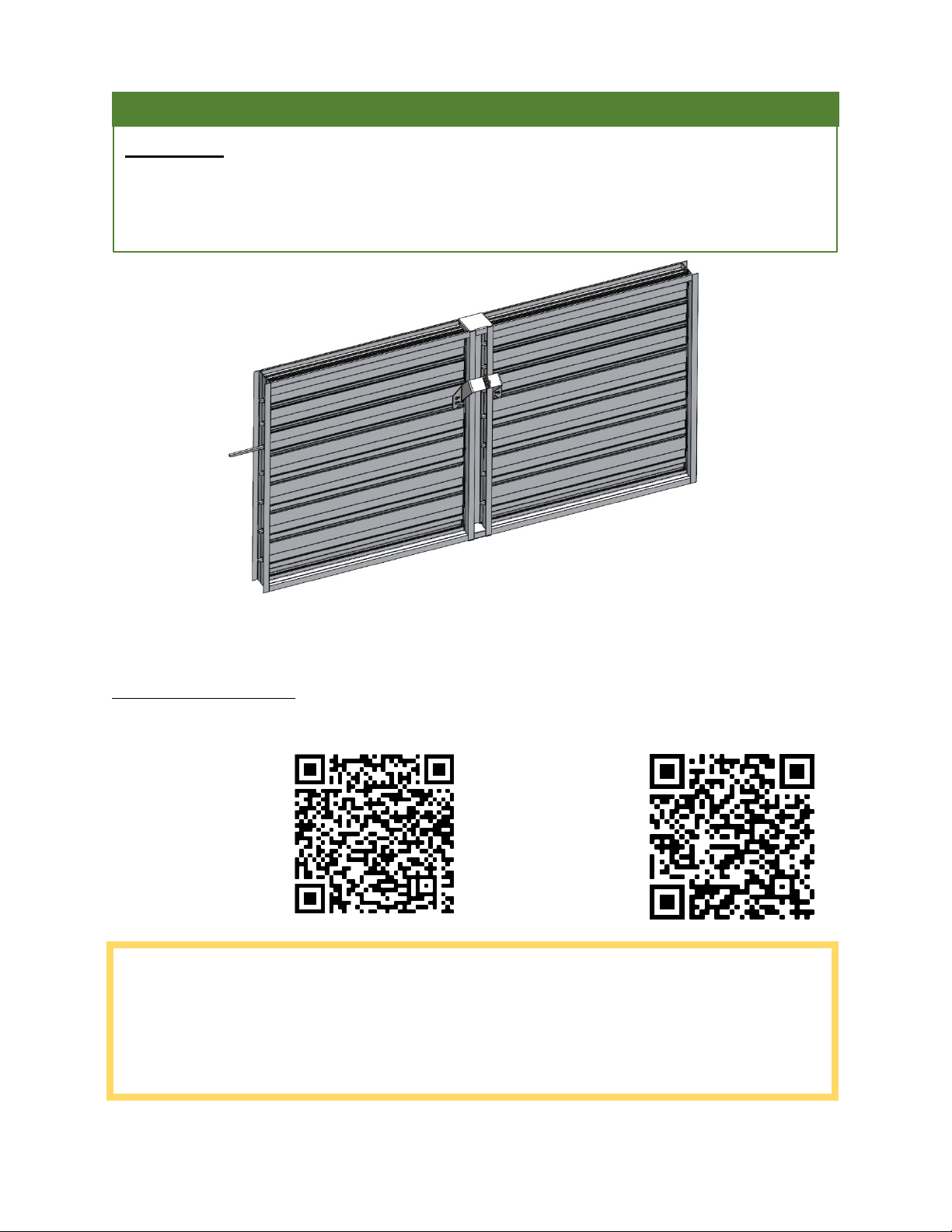

1) Review the schedules to see where the dampers should be installed in the building. Inspect the

damper for any signs of damage and dirt.

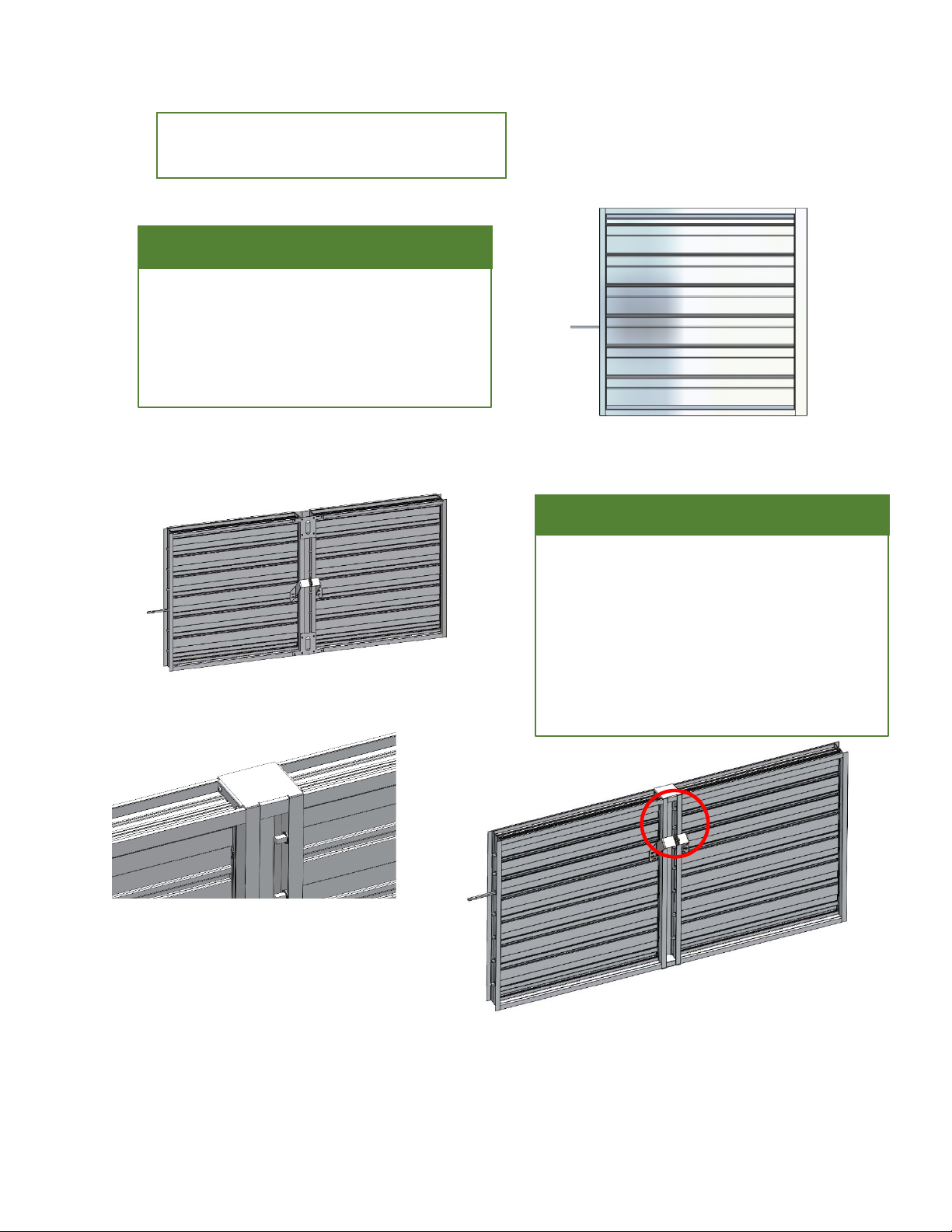

2) When moving the damper, only use the frame or sleeve. Do not use the blades, linkage, actuators,

or jackshafts to lift the damper as this could cause damage. Use enough support to raise each

section mullion uniformly when handling multi section dampers (see drawing). Avoid excessive

bending, twisting, or racking. The damper must not be dragged or stepped on.

3) Damper blades need to open and/or close properly. It is not recommended to install screws in the

damper frame that interfere with the blade linkage and prohibit this.

4) When putting dampers in ducts or apertures they need to be square and not have any twists.

Squeezing or stretching the damper into the duct or hole is NOT recommended. Dampers that

experience excessive leakage and/or torque needs that exceed damper/actuator design might result

from out of square, racked, twisted, or misaligned installations.

5) Before and after installation, the damper and actuator must be kept clean, dry, and free of debris,

dust, and other foreign materials. Metal shavings, sand, drywall dust, fireproofing materials, plaster,

and paint overspray are all examples of foreign materials.

6) If wall texturing or spray painting will be done within 10 feet (3 metres) of the damper, the damper

should be adequately covered to prevent overspray. Needless dirt and debris on the damper can

result in a higher chance of leakage and/or torque needs that are higher than the damper/actuator

design.

7) In order to maintain, inspect, and service the dampers, appropriate access to dampers and actuators

is needed. It will be required to install a removable section of duct if satisfactory size access cannot

be accomplished.

Electrical Guidelines:

All electrical and or pneumatic connections to damper actuators should be made in accordance with

applicable codes, ordinances and regulations according to region.

Pre-Installation Guidelines

The goal of a suitable installation is to attach the control damper into the opening in such a

way that damper action is not distorted or disrupted. The checklist below will help you

complete the damper installation in a timely and efficient manner.

An electrical input may be needed for this

equipment. This work should be performed by

a qualified electrician only.

Please verify power requirements before

wiring the actuator. Alumavent is not

responsible for any damage to, or failure of the

unit caused by incorrect field wiring. Electrical

and/or pneumatic connections to damper

actuators should be made in accordance with

wiring and piping diagrams developed in

compliance with applicable codes, ordinances

and regulations.