Johnson Controls BD-1300 User manual

Other Johnson Controls Fire And Smoke Damper manuals

Johnson Controls

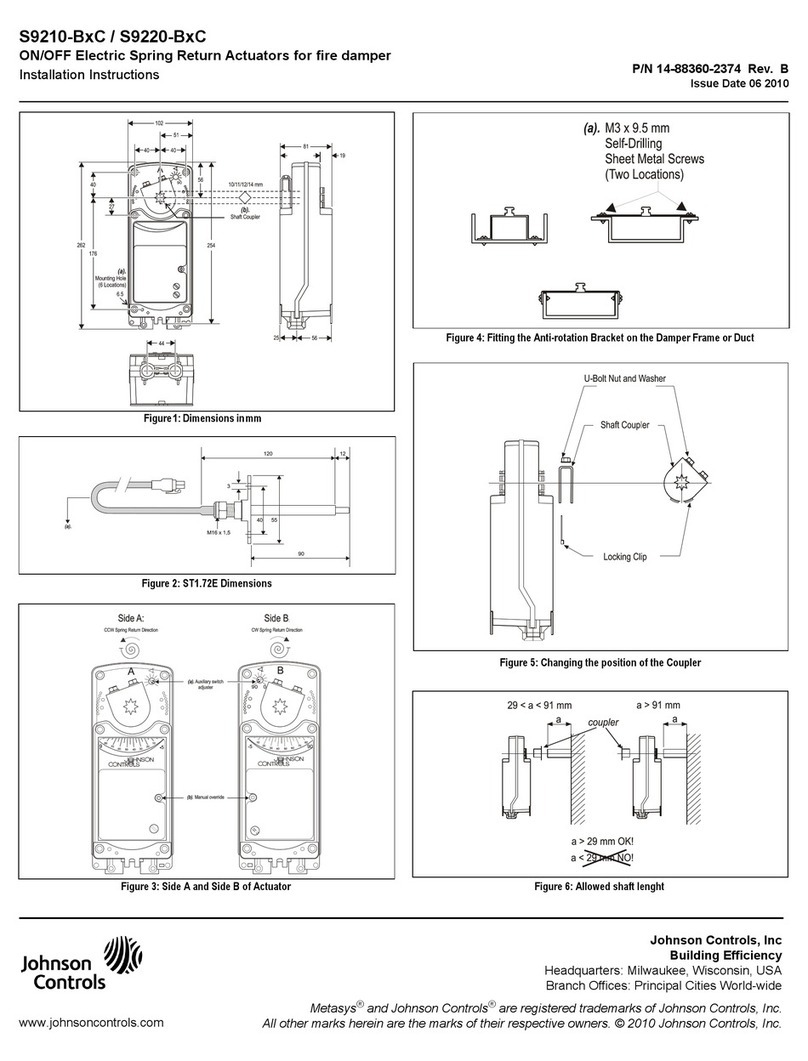

Johnson Controls S9210-BC Series User manual

Johnson Controls

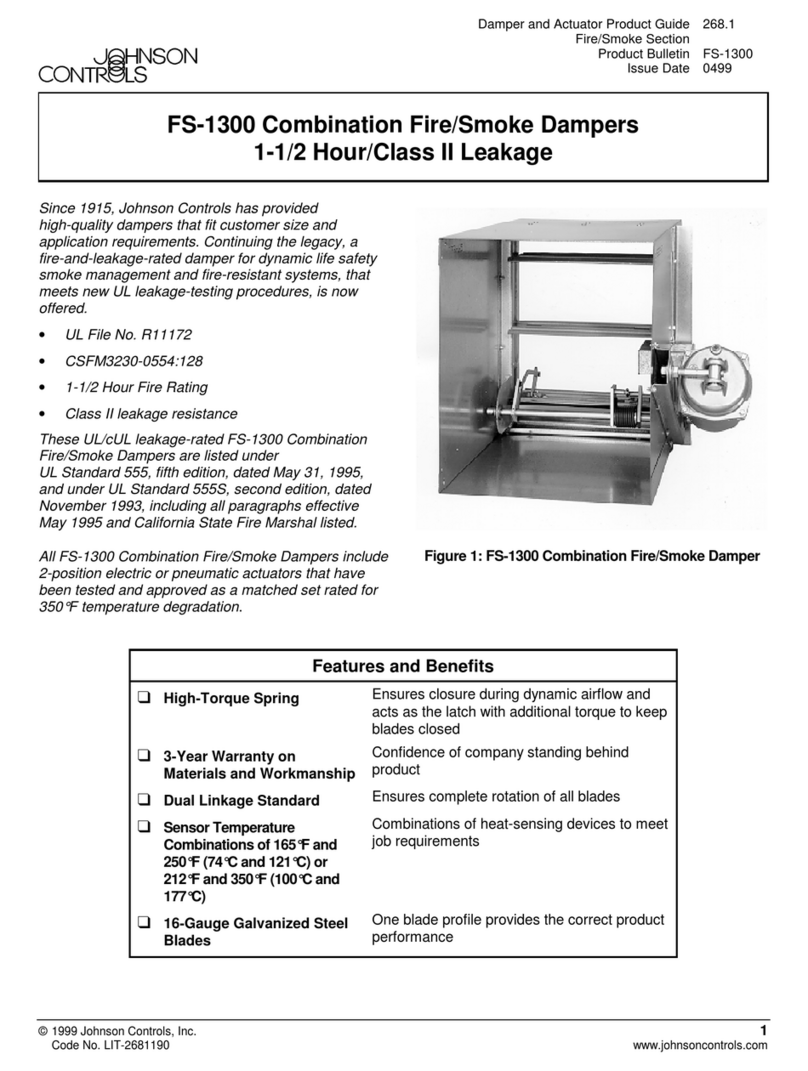

Johnson Controls FS-1300 User manual

Johnson Controls

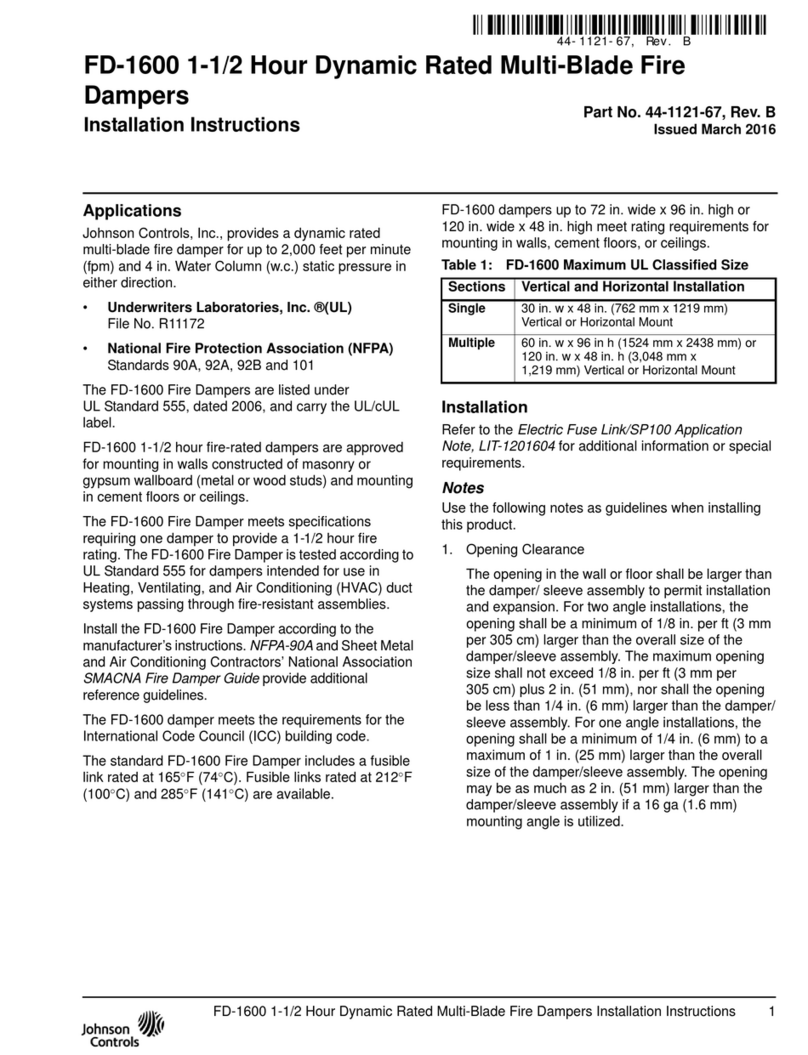

Johnson Controls FD-1600 User manual

Johnson Controls

Johnson Controls YORK ACTIVA 100 User manual

Johnson Controls

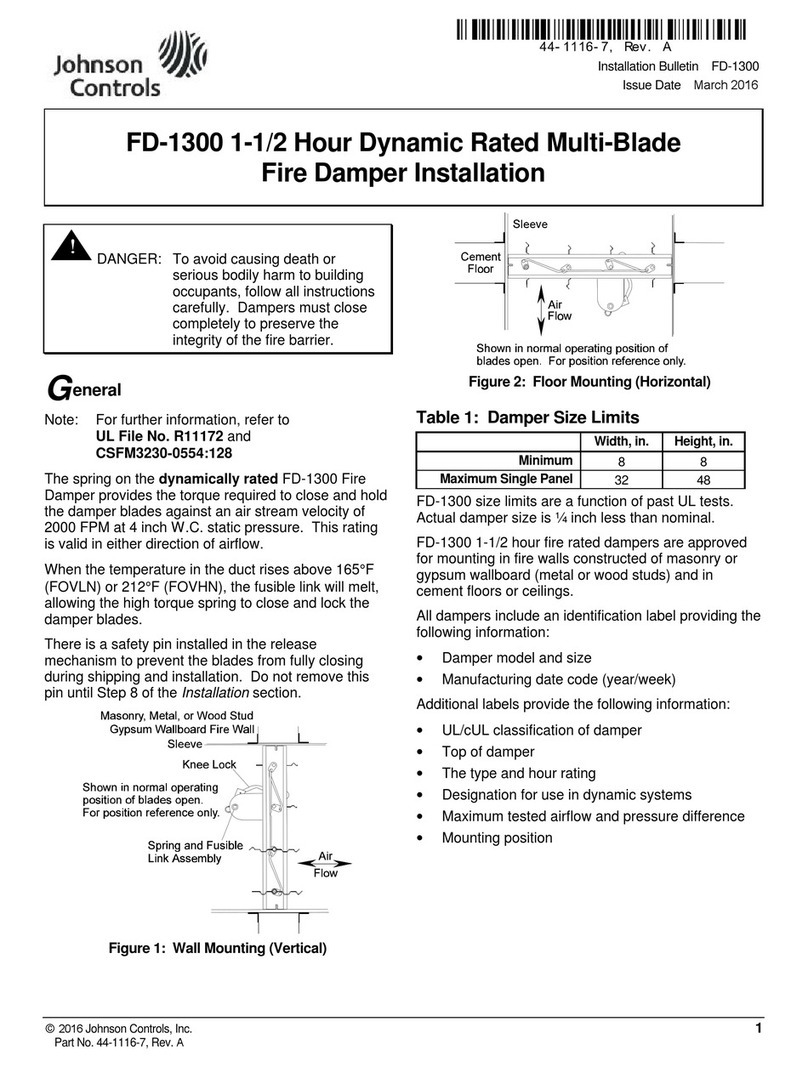

Johnson Controls FD-1300 User manual

Johnson Controls

Johnson Controls RF-2000 User manual

Popular Fire And Smoke Damper manuals by other brands

HVC

HVC NCA 700 Series Operation and maintenance manual

Wildeboer

Wildeboer FR90 user manual

FläktGroup

FläktGroup ETCE Instructions for installation, operation and maintenance

Tamco

Tamco 1000 SM Series manual

Greenheck

Greenheck Vektor-MD Installation, operation and maintenance manual

Lindab

Lindab FBC2 Installation booklet

EKOVENT

EKOVENT EKO-SRB1 Installation, operating and maintenance instructions

Greenheck

Greenheck HBS Series Installation, operation and maintenance instructions

Advanced Air

Advanced Air 0160 Series Installation, operation and maintenance manual

Greenheck

Greenheck CRD-1WT Installation, operation and maintenance manual

Swegon

Swegon Actionair CSS Series installation guide

TAKACHIHO

TAKACHIHO FYN-M 1 Series manual