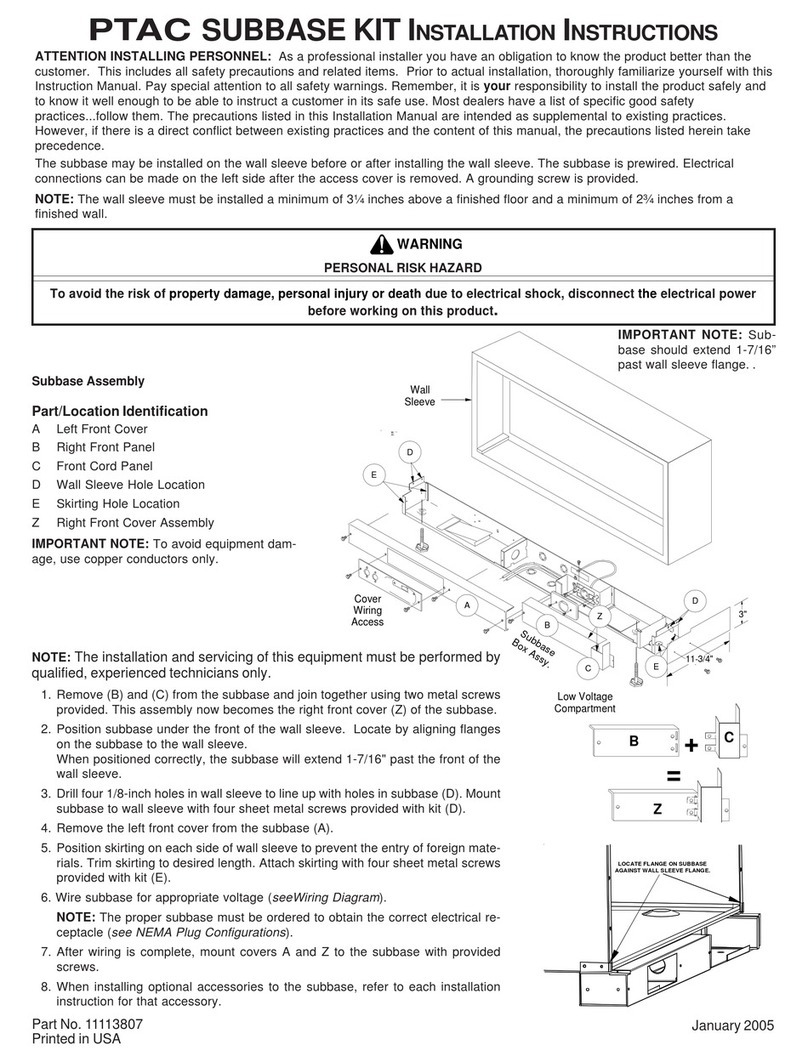

3

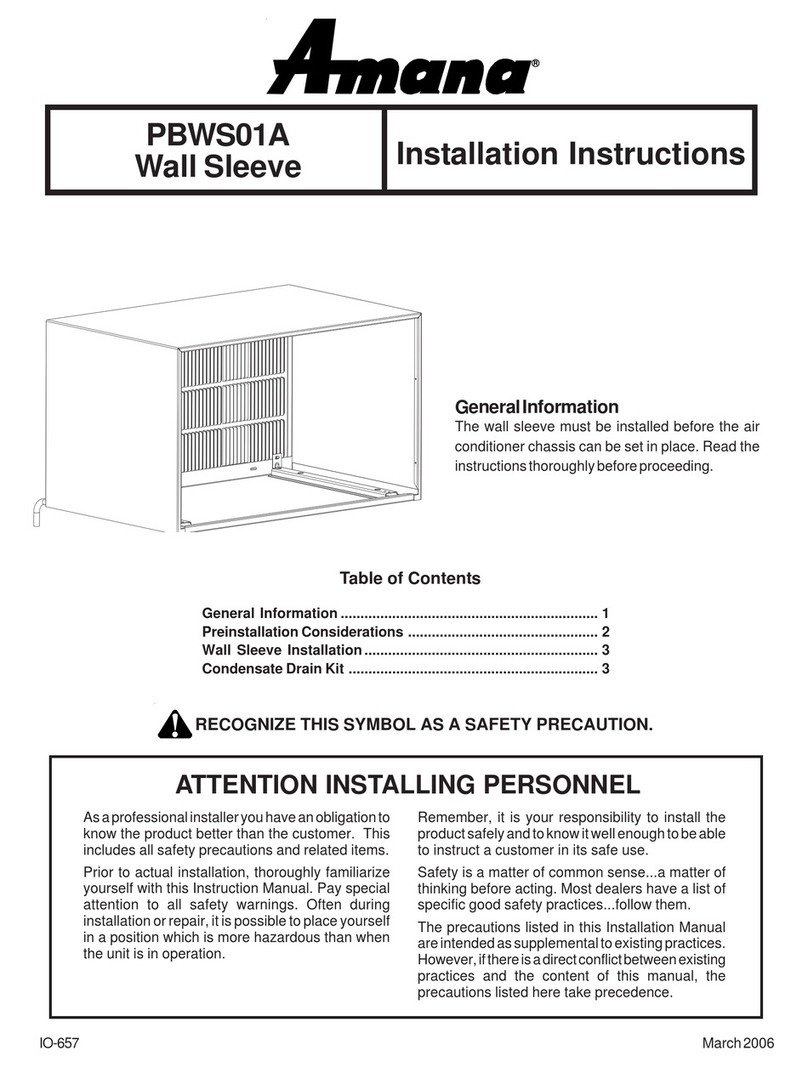

• The wall opening must be the correct size. See

Figure1forwallsleevedimensionsand Figure3for

minimum wall opening size.

• Thewall sleeveneedsto beinstalledwith minimum

clearances to the floor and adjacent walls. Minimum

projectionsof thesleeve intoand outof the room

will also have to be met. See Figures 2 and 4 as

well as Table 1 for details.

• If installed in a concrete or masonry wall, a lintel

mustbeprovidedinthe wall opening forsupport.Do

not use the wall sleeve as a lintel. See Figure 5

for a typical lintel construction.

• When installed in the opening, the wall sleeve must

be horizontally level from side to side and pitched

(one quarter bubble in the sight glass) to the

outside. DO NOT SLOPE THE WALL SLEEVE

TOWARDTHEROOM.

• The installer must determine and supply the

mounting bolts and/or screws to attach the wall

sleeve to the sides of the wall opening. Make sure

thewallopeningisadequate for strongsupport.

• Theinstallermustprovideadequatesealingand

insulation around the sleeve after it is installed. See

Figure 6 for one of many types of constructions.

• Ifused,a208/230-voltwall receptacle must be

located within 58 inches of the lower right sleeve

corner. Extension cords must not be used with the

unit. See the note on Figure 1.

Note: Additional extension kits are not allowed beyond

the 24” wall sleeve depth.

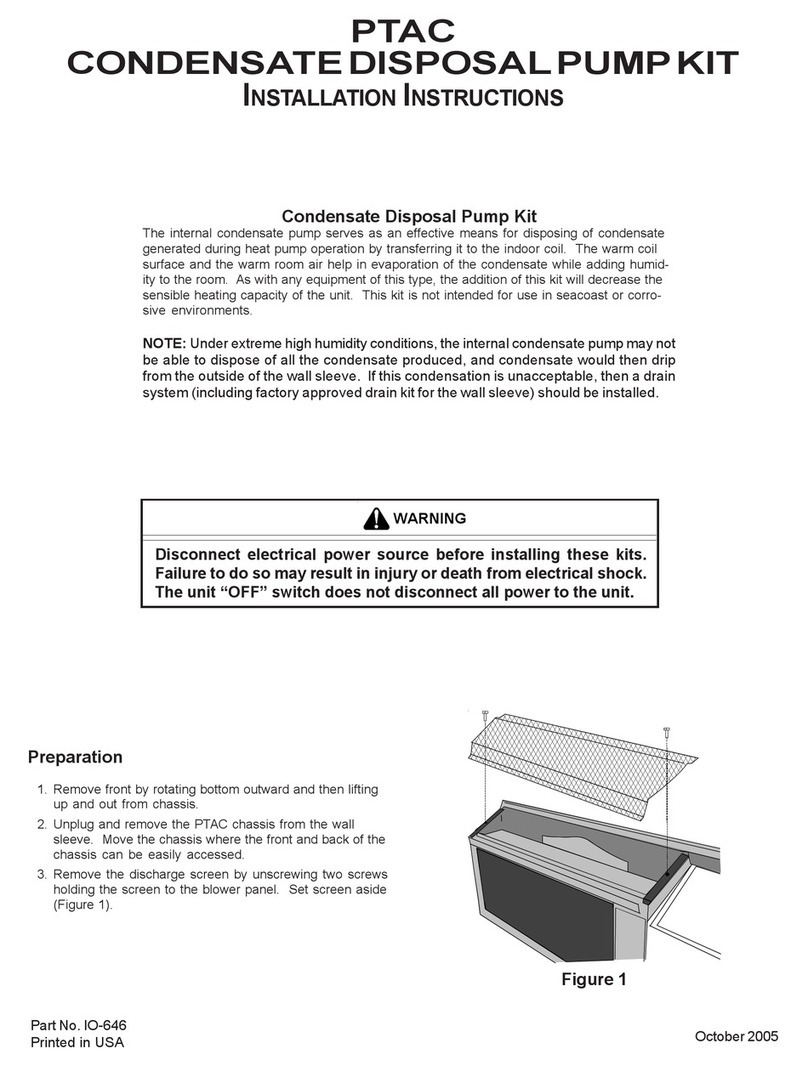

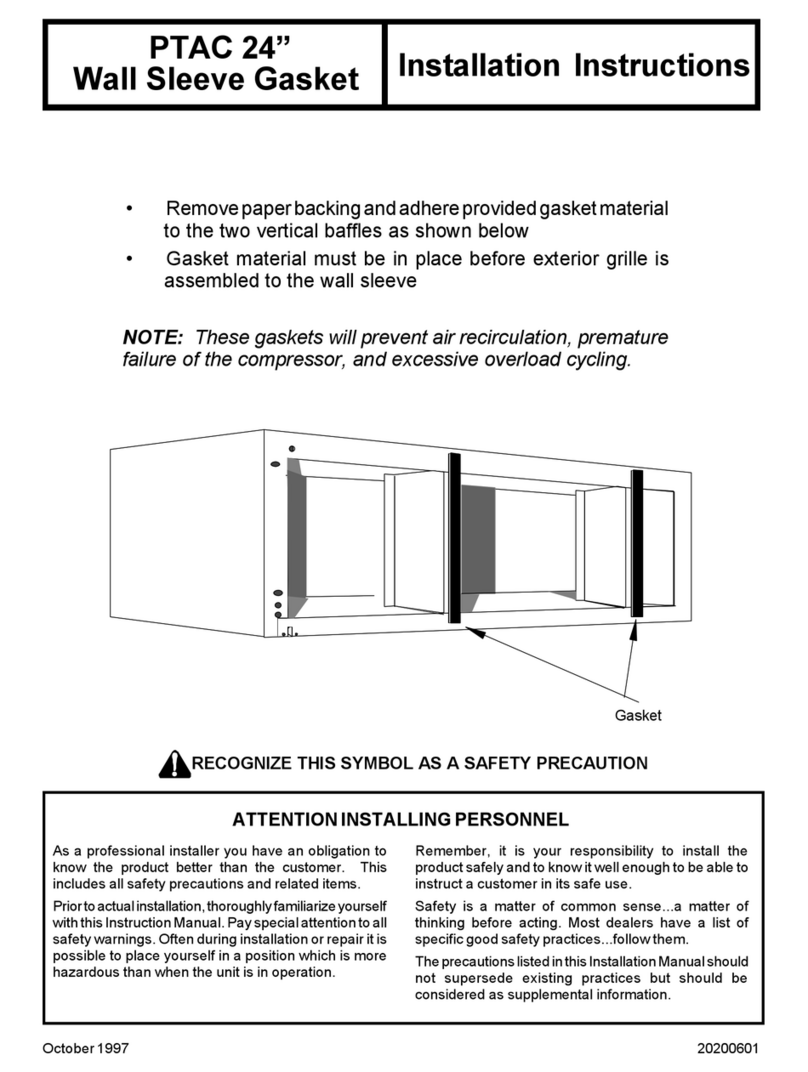

OUTDOORENCLOSUREPANELREMOVAL

The sleeve stiffener must be taken out before the

enclosure panel can be removed from the sleeve.

1. Remove the zig-zag folded cardboard sleeve stiff-

ener (Figure 7).

2. Grasping the top and bottom flanges of the rear clo-

sure panel as shown in Figure 8, pull the entire panel

out diagonally from one side.

Install the wall sleeve condenser air grille by using the

screws and holes provided. (See the Installation In-

structions provided for the grille kits.)

WOOD

FRAME

LINTEL

Figure 5 - Framing with Lintel

STEEL

LINTEL

CAULK TOP,

BOTTOM, AND

BOTH SIDES

1/4"

6 mm

MINIMUM

PROJECTION

CONCRETE

LINTEL

POWER SUPPLY

CONDUIT

RECEPTACLE

FINISHED

FLOOR

13 1/2" (340 mm)

MAXIMUM

(NO ACCESSORIES)

16" - 24"

406mm - 610 mm

CAULK TOP,

BOTTOM, AND

BOTH SIDES

Figure 6 - Block and Brick Veneer Installation

Sleeve

Stiffener

Figure 7- Sleeve Stiffener Removal

Figure 8 - Panel Removal

PRE-INSTALLATIONCONSIDERATIONS

Beforeproceedingwiththesleeveinstallation,ensurethefollowingguidelinesforlocatingthewallopeningandsleeveare

met.