6

U-CLIP

PLASTIC

CONNECTOR

VALVE

Figure 16

STEAM AND WATER PLUMBING

1. The plumbing can enter from the left and/or right side of

the unit through the slots and holes that are supplied in

the hydronic top assembly. (See Steam and Water

Plumbing Dimensions figures.)

2. Hydronic water kits (HWK03E may have water entering

either the left or right side of the coil. Hydronic steam kits

(HVK03E)can only have enteringsteamontheright side

of the coil. (See Steam and Water Plumbing Dimen-

sions figures.)

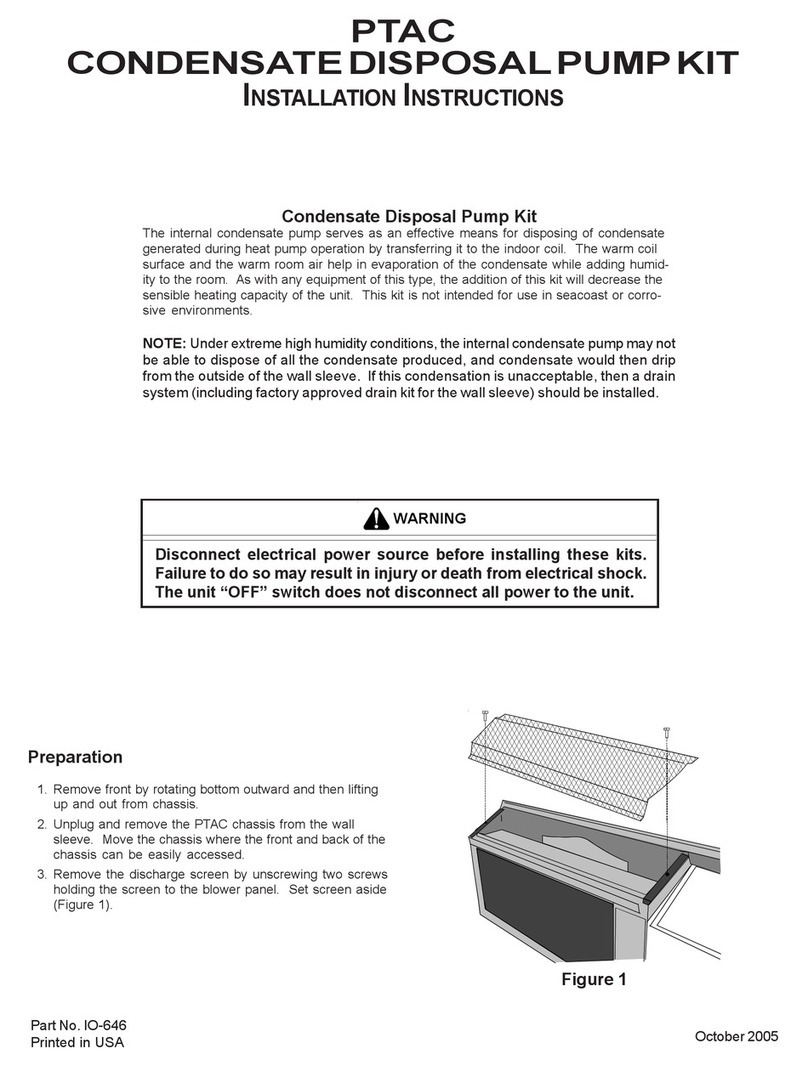

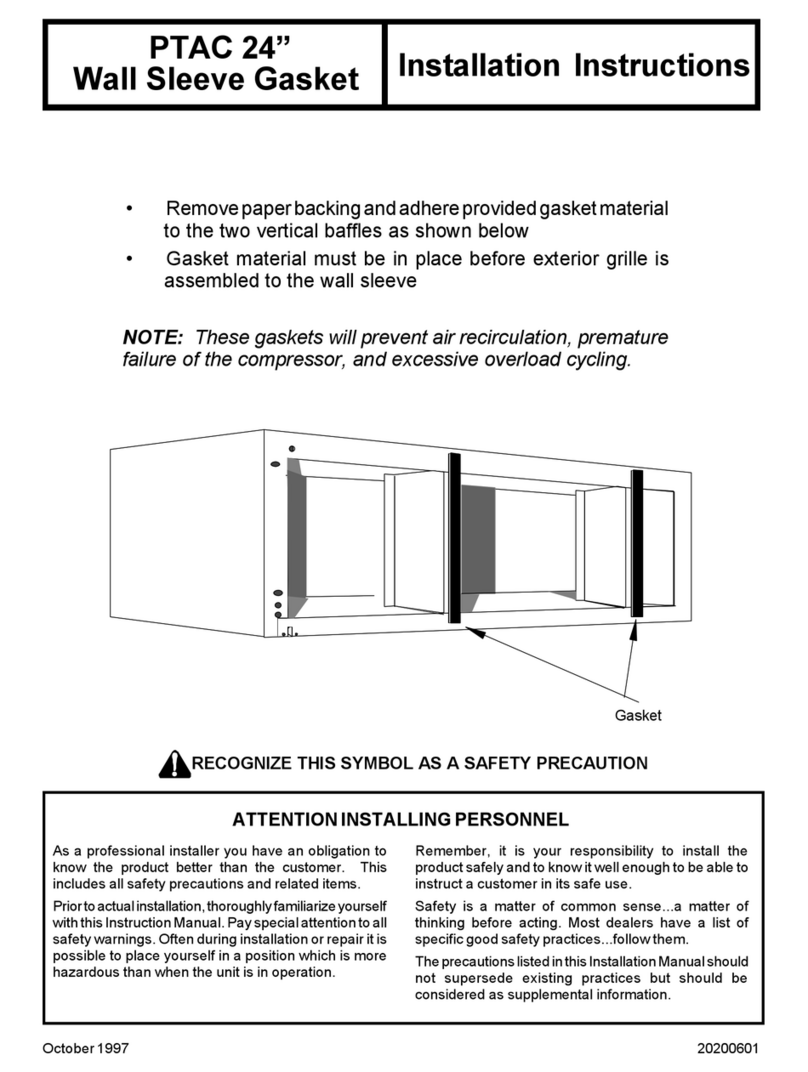

3. Make sure all piping is plumbed to the coil and system

has been bled of air. Using the existing six screws and

hydronic top from Step 13, place the top cover over the

coil deck assembly. Make sure the back flange of the

top cover fits inside the small vertical flange in the back

of the coil assembly. (Figure 17.)

Flange

Hydronic

Coil

Water

Piping

Figure 17

NOTE: A manual bleed valve is supplied with both the

Hydronic Water and Hydronic Steam Kits (HWK03E and

HVK03E). It is recommended that an automatic bleed valve

for Hydronic Steam Kits (HVK03E) be installed. This will

eliminate frequent access to the manual bleed valve for

purging air from the steam system.

FINALKITINSTALLATIONSTEPS

1. Place the hydronic front on the top assembly so the

flanges of the front fit tightly into the flanges of the top

assembly.

2. Ensure the inlet air filter is located inside of the inlet grille

and held in position with the four brackets (one on each

side and two on the bottom). The inlet grille can be

hinged open by unlatching the two top levers on the

grille.

3. To service the unit, remove the front. Remove the four

sheet metal screws that secure the unit to the wall

sleeve from each of the side seal mounting brackets. If

a subbase is used, remove the right side cover panel

from the subbase and disconnect the power cord. The

chassis may be removed for service.

NOTE: To prevent water hammering, the use of approved

motorized valves and good piping practices is strongly

recommended. Opening and closing motorized valves very

slowly will help prevent water hammering.

CONFIGURATIONSETTINGSFORR410A

ESERIESMODELBOARDS

The control can be configured to operate a wide range of

options. The options listed below with the * are the factory

default settings. If these are acceptable, then the unit does

not require any additional configuration and is fully operable.

To configure the unit, first select the configuration feature

code setting and then an option code to change from the

factory default setting.

To enter configuration feature mode:

1. Pressandhold the up anddown arrow keys atthe

same time and press theOFF key twice within

a two (2) second time frame. The display will indi-

cate - -., and then release the key and press the

key one time. The display will then alternate be-

tweenC1 and 0.

Toselect adifferentconfiguration feature code,press

the HEAT key until the desired configuration

comesup.Toscrollto apreviouslyviewed configura-

tion codes press the COOL key.

Once you have scrolled to the correct feature, then to

selectthe option code foryour desired configuration,

press either the up or down key to scroll through

the options of the selected feature code.

To exit configuration mode:

1. Press the OFF key. Configurationfeature

mode will also exit if no keys are pressed for a pe-

riodof two (2) minutes.