4

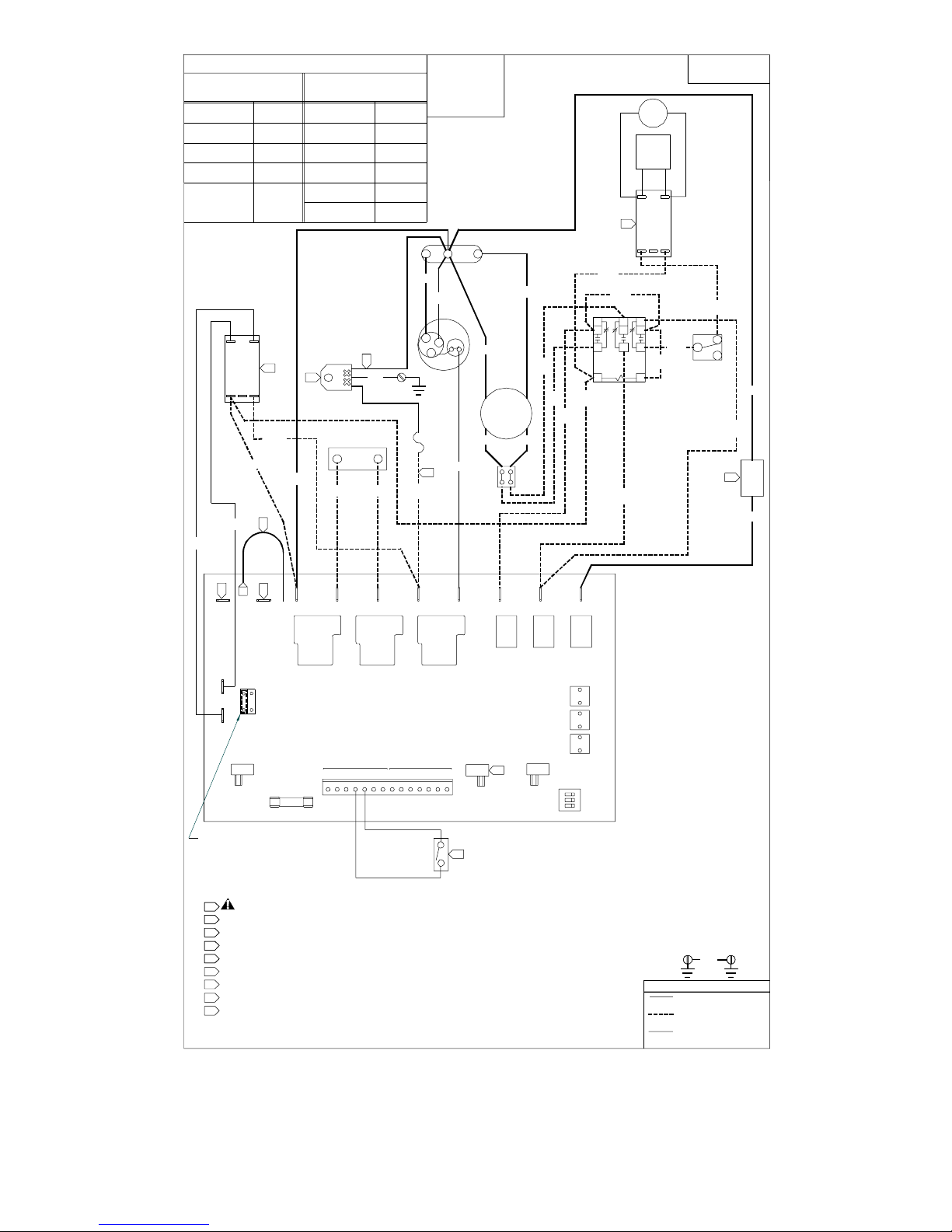

WIRING INSTRUCTIONS

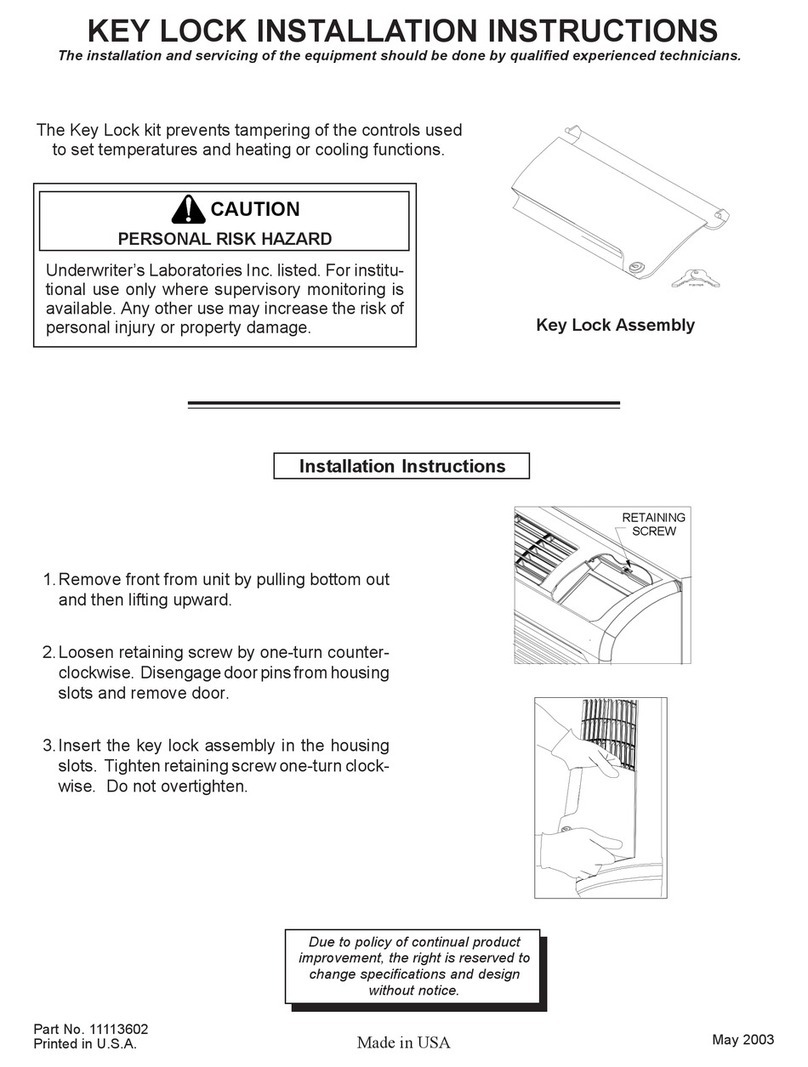

1. To gain access inside the control panel, remove the control

knobs and escutcheon, remove the three screws holding the

panel in position, and tilt control panel forward, being careful

not to pinch any wires (Figure 13).

123

ON

SCREW

SCREW

SCREW

Figure 13

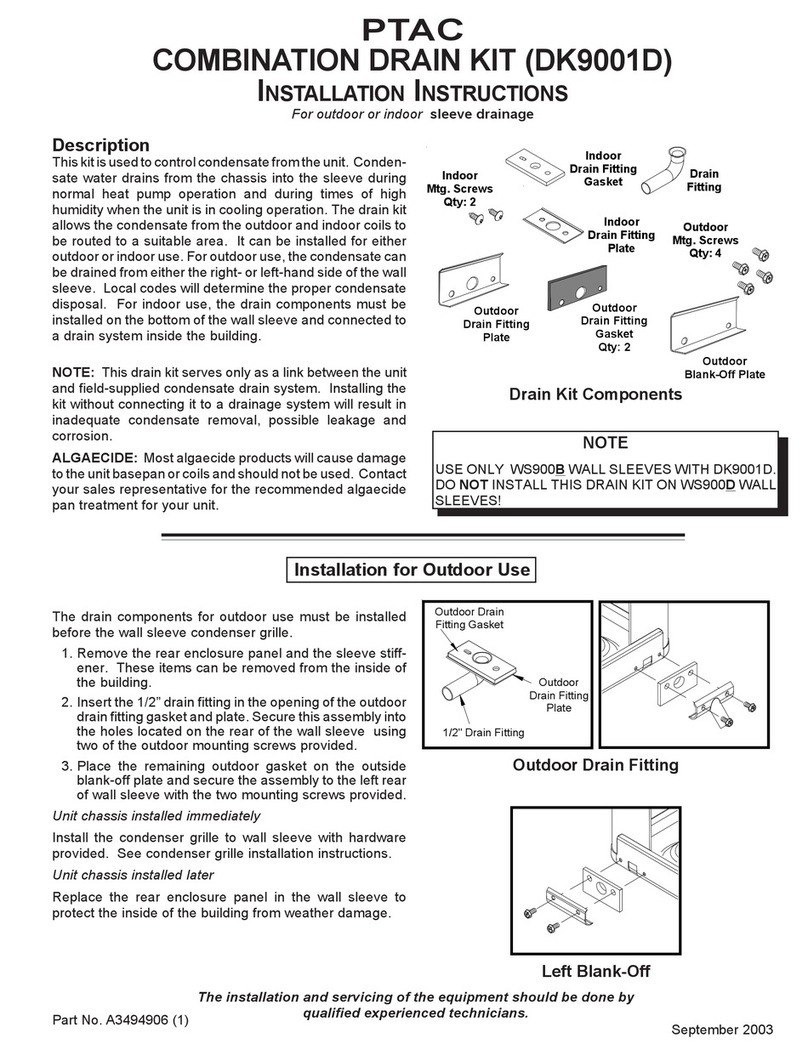

2. Lift the control panel up so the control panel is free of its

hinges. Orient the control panel so there is easy access for

mounting components to the control panel (Figure 14).

Figure 14

3. Using the two #8 screws that are provided, screw the

transformer to the control panel in the transformer mounting

holes provided in the panel.

4. Mount the relay in one of the three relay mounting holes in

the control panel making sure that the threaded stud is in the

smaller hole and the metal tab is in the adjacent hole. Screw

the provided nut onto the threaded stud from the opposite

side of the control panel.

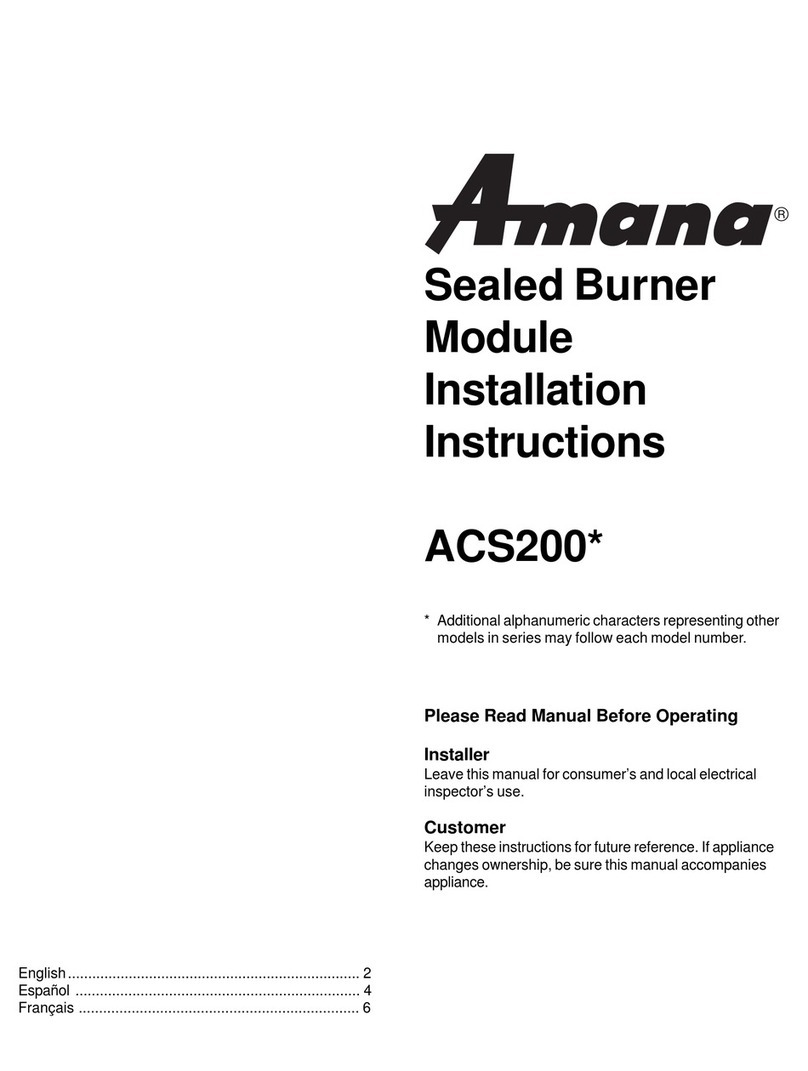

5. Remove the knockout for the vent switch (Figure 15) located

in the control panel and snap the vent switch in the knockout

hole with the terminals inside the control panel compartment.

The numbers on the switch should be facing toward the

control board. Place the supplied label just above the

switch.

Vent Switch

Knockout

Vent Switch

Figure 15

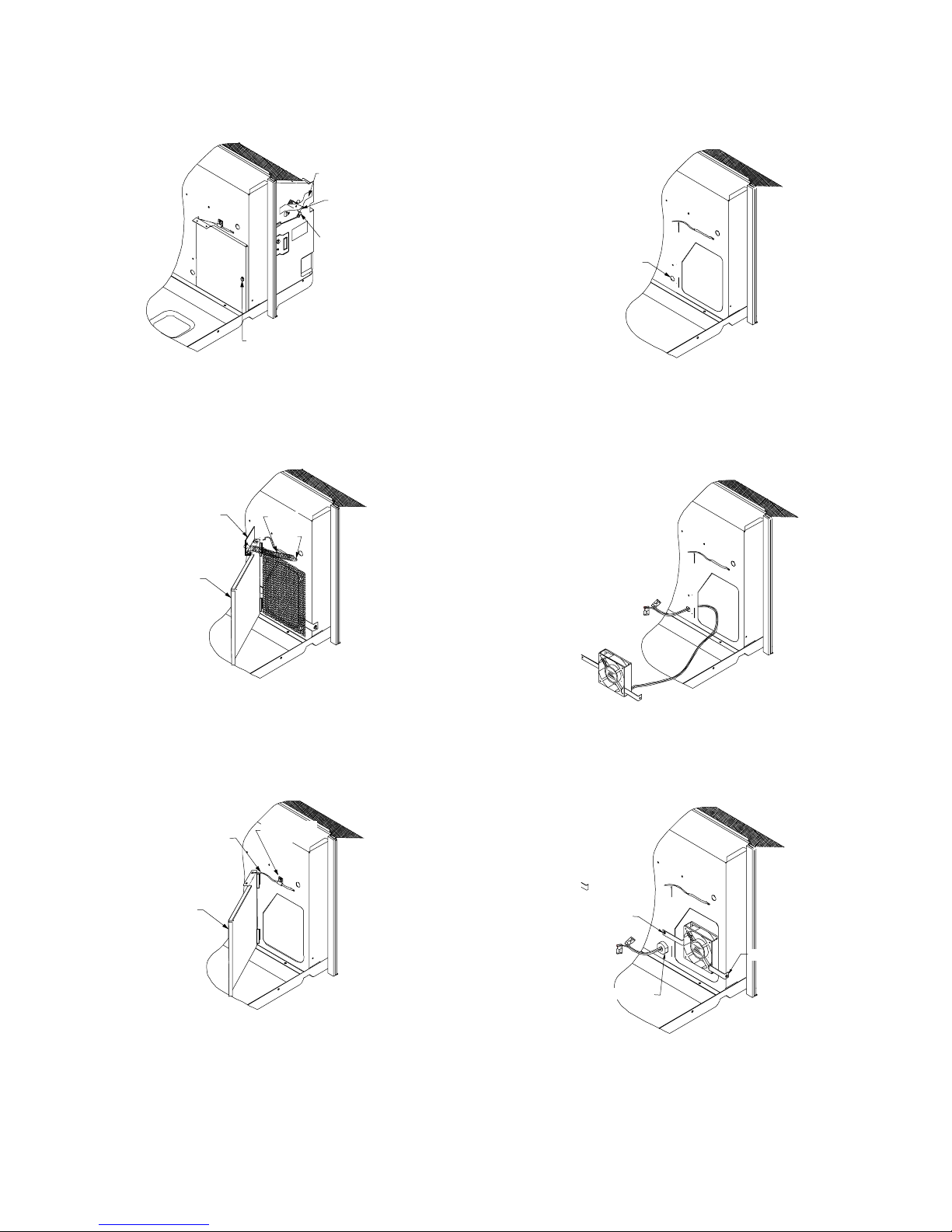

6. Using the two provided #8 screws, attach the terminal strip to

the partition panel inside the control panel compartment

(Figure 16).

Terminal

Strip

BK16

RD17

BK17

RD14

Figure 16

7. Once the wires are routed into the control panel compart-

ment, attach the door motor and vent fan (for PVK kits)

terminals to the 24 volt side of the transformer (see Wiring

diagrams).

8. Take BK 16 and RD17 fan motor wires from the control

board and place on the terminal strip (Figure 16).

9. Take BU10 wire from the #3 terminal of the relay and place

on the control board FAN LOW terminal. Take the BU15 wire

from the #8 terminal of the relay and place on the piggyback

terminal of BU10.

10. Take the BU4 wire from the #4 terminal of the relay and

place on the control board FAN HIGH terminal.

11. Please refer to the following schematics for proper electrical

wiring if the chassis has any of the following kits previously

installed:

Power Vent Kit

Power Door Kit

Hydronic Heat Kit

Hydronic Valves