American Changer Corp. AC401-2 Setup guide

Popular Change Machine manuals by other brands

American Changer

American Changer AC6007 installation guide

American Changer

American Changer AC2007 installation guide

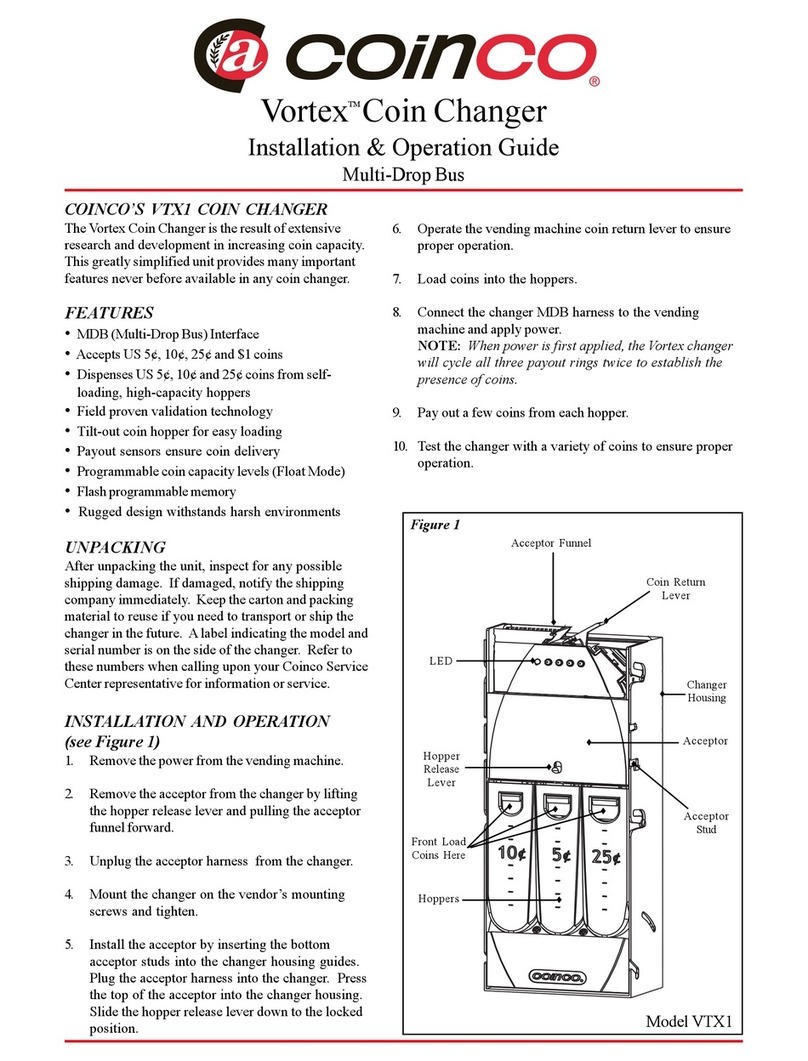

Coinco

Coinco vortex Installation & operation guide

Coinco

Coinco Guardian 6000 manual

Comestero

Comestero Suzohapp Multi PRO operating manual

Alberici

Alberici Hira 2 Series Operator's manual

Coinco

Coinco CoinPro 3 Operation and service manual

Hamilton Manufacturing Corporation

Hamilton Manufacturing Corporation DRS Operational manual

Alberici

Alberici HammerOne S11 Operator's manual

Vetus

Vetus IVPS Operation manual and installation instructions

Alberici

Alberici Spike CM Arm Operator's manual

MEI

MEI EC6000 Startup guide