8Amico Pipeline

2. ANNUNCIATOR MODULE

The Annunciator Module contains the buzzer, a “Power On” LED, the “TEST” and the

“ALARM MUTE”buttons. The function of the“TEST”button is to verify that the buzzer and all

the LED’s are in working condition. An alarm will be heard when this button is pushed and

all the LED’s will light up. When the button is released, the alarm will silence. The “ALARM MUTE”

button is used to silence an alarm that has occurred. This module also contains a fail-safe relay

that de-energizes when the buzzer is activated. This relay can be used with the “Amico remote

buzzer”, for applications requiring a remote audible alarm (see Appendix B), for connection to

another Amico Alarm or a Building Management System.

3. BLANK MODULE

The Blank Module is used as a ller board for future provisions of the alarm.

Amico Microprocessor Based Alarm

Page: 8

DESCRIPTION OF MODULES

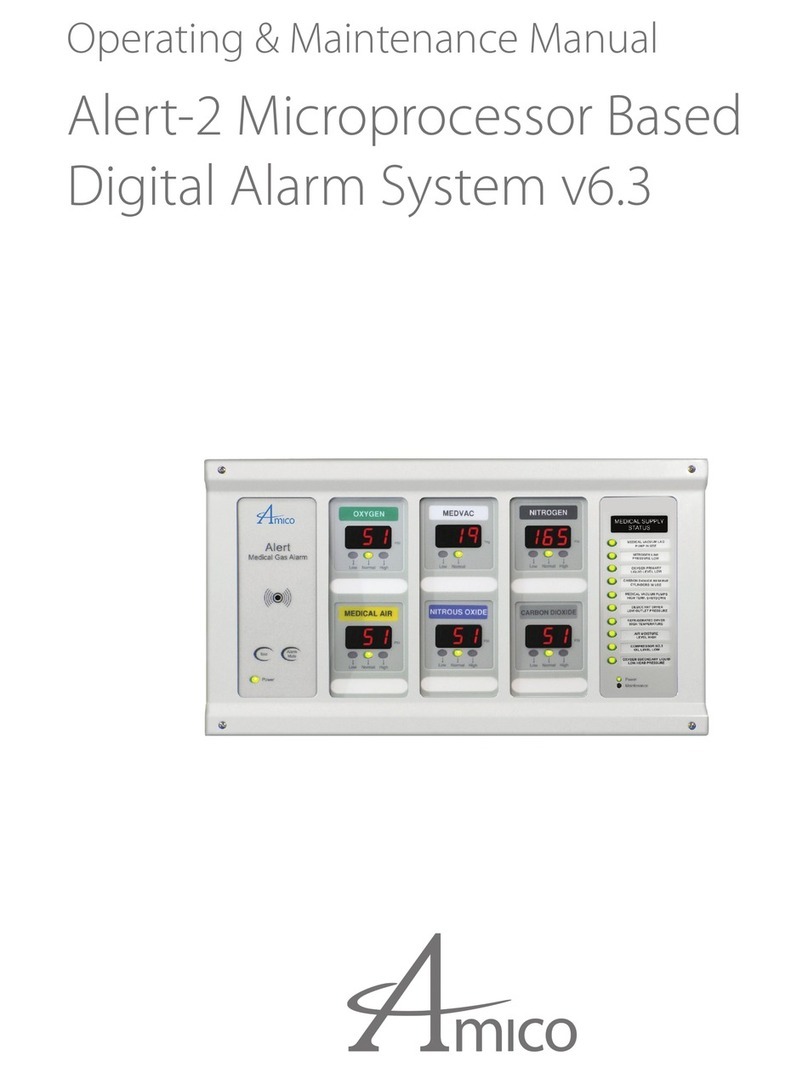

The ALERT-2 alarm is divided into (4) or (7) main modules:

COMMON TO ALL ALARMS

1. SYSTEM POWER SUPPLY

The System Power Supply has been pre-installed into the back box

assembly. The System Power Supply converts the AC voltage supply to

the alarm into two voltages: 5 VDC (regulated) required by the

microprocessor hardware and 15 VDC (unregulated) required by the

buzzer and the LED’s. This unit also contains the main ON/OFF power

switch, the transformer, the heat sink, the main fuse and fuse cover, the

rectifying circuitry, the terminal blocks and the low voltage DC power

cable for connecting this unit to the annunciator module. The System

Power Supply can be easily removed and reinstalled by unscrewing it

from the back box.

2. ANNUNCIATOR MODULE

The Annunciator Module contains the buzzer, a “Power On” LED, the

“TEST” and the “ALARM MUTE” buttons. The function of the “TEST”

button is to verify that the buzzer and all the LED’s are in working condi-

tion. An alarm will be heard when this button is pushed and all the LED’s

will light up. When the button is released, the alarm will silence. The

“ALARM MUTE” button is used to silence an alarm that has occurred. This

module also contains a fail-safe relay that de-energizes when the buzzer

is activated. This relay can be used with the “Amico remote buzzer”, for

applications requiring a remote audible alarm (see Appendix B), for

connection to an other Amico Alarm or a Building Management System.

3. BLANK MODULE

The Blank Module is used as a filler board for future provisions of the

alarm.

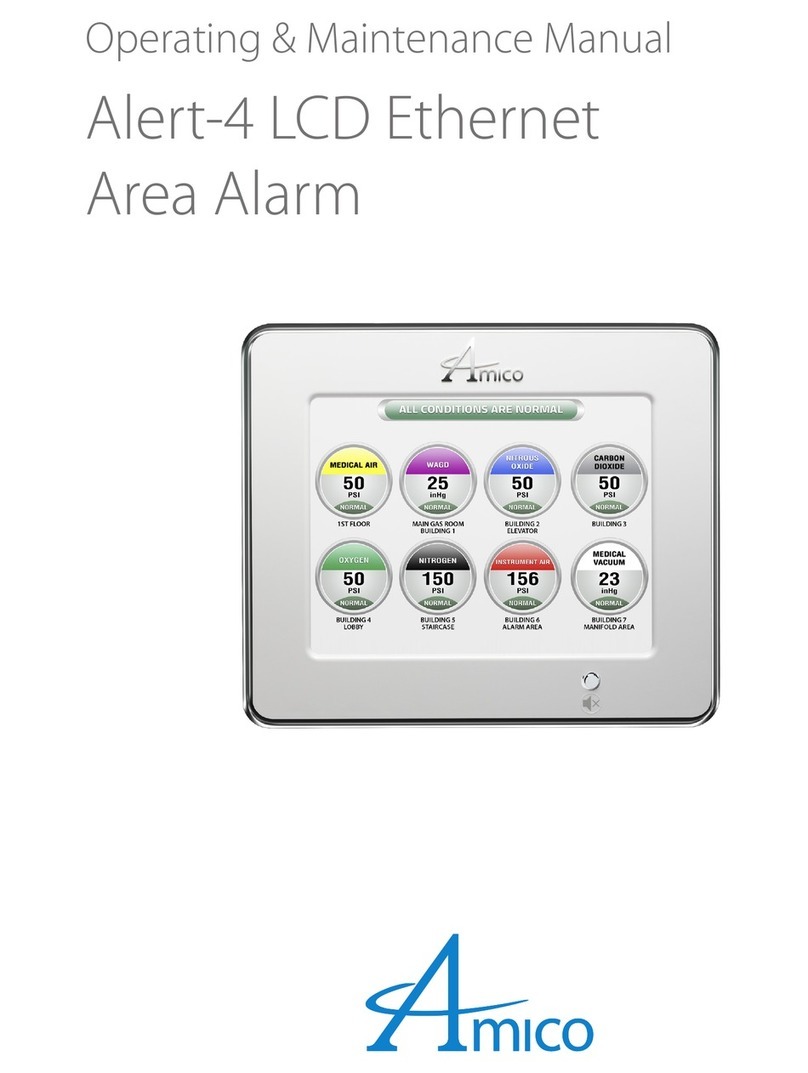

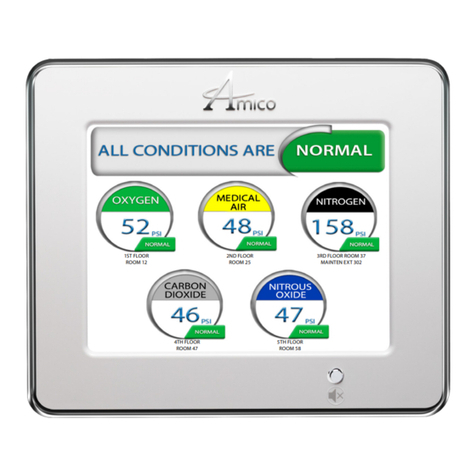

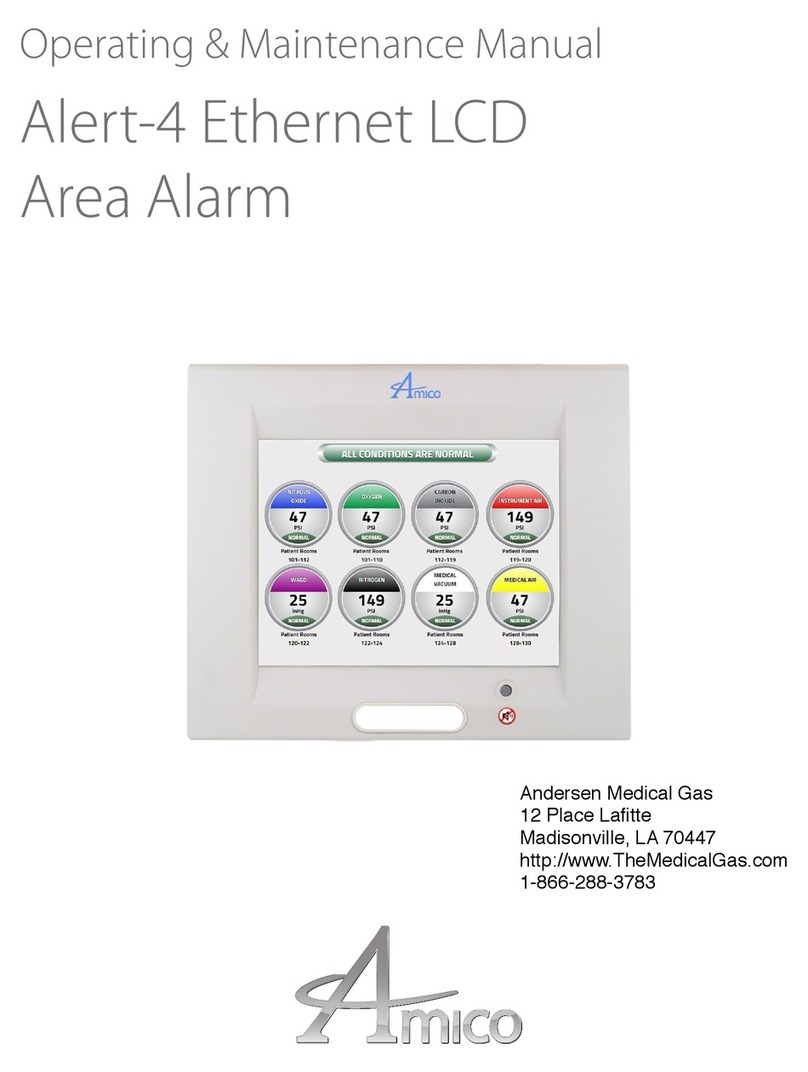

AREA ALARM

4. AREA DISPLAY MODULE

The Area Display Module provides a digital display of the actual pressure/vacuum of a

gas being monitored. In addition a gas trend indicator bar with HIGH and LOW alarms

are displayed. The trend bar has three coloured LED’s: Green for Normal condition, YELLOW

for Caution condition, and RED for high and low Alarm conditions.

Each display module contains a gas specic colour coded label (USA or ISO colours are

available). A space is also provided, at the base of the module, to identify the location that

the display module monitors. The display module is eld adjustable for pressure/vacuum

settings, repeat alarm, and units of measure. Whenever the module is in calibration mode,

the bargraph is ashing, indicating the calibration mode. Dry contacts for high and low

alarms are available for remote monitoring of each module.

5. 2 IN 1 DISPLAY MODULE

The 2 in 1 Display Module provides a digital display of the actual pressure/vacuum of the

gas being monitored. In addition, a gas trend indicator bar with High and Low alarms are

displayed. This module has two coloured LEDs - Green for Normal conditions and Red for

High and Low alarm conditions. It is eld adjustable for pressure/vacuum settings, repeat

alarms, and units of measure. Dry contacts for high and low alarms are available for remote

monitoring of each module.

Each module will continuously monitor up to 5 signals from source equipment or pressure

switches. If any of the signals being monitored go into an alarm condition, a Red LED will

illuminate and the audible alarm will sound.

PLEASE NOTE: Contacts located on back of module are Dry Contacts only.

DO NOT apply any voltage.

Alert - 2 Series

Page: 9

AREA ALARM

4. AREA DISPLAY MODULE

The Area Display Module provides a digital display of the actual

pressure/vacuum of a gas being monitored. In addition a gas trend

indicator bar with HIGH and LOW alarms are displayed. The trend

bar has three coloured LED’s: GREEN for Normal condition, YEL-

LOW for Caution condition, and RED for high and low Alarm

conditions.

Each display module contains a gas specific colour coded label

(USA or ISO colours are available). A space is also provided, at the

base of the module, to identify the location that the display module

monitors. The display module is field adjustable for pressure/vacuum

settings, repeat alarm, and units of measure. Whenever the module

is in calibration mode, the bargraph is flashing, indicating the calibra-

tion mode. Dry contacts for high and low alarms are available for

remote monitoring of each module.

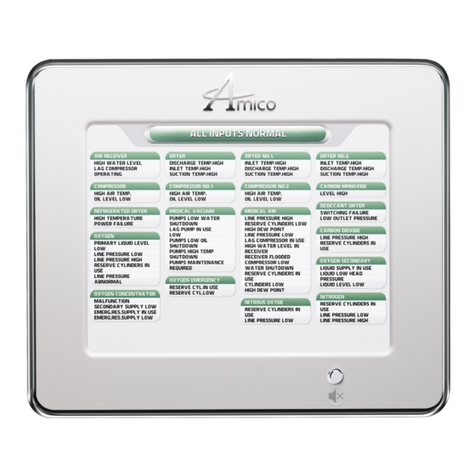

5. 2 IN 1 DISPLAY MODULE

The 2 in 1 Display Module provides a digital display of the actual

pressure/vacuum of the gas being monitored. In addition, a gas

trend indicator bar with High and Low alarms are displayed. This

module has two coloured LEDs - green for Normal conditions and

red for High and Low alarm conditions. It is field adjustable for

pressure/vacuum settings, repeat alarms, and units of measure.

Dry contacts for high and low alarms are available for remote

monitoring of each module.

Each module will continuously monitor up to 5 signals from source

equipment or pressure switches. If any of the signals being

monitored go into an alarm condition, a red LED will illuminate and

the audible alarm will sound.

Please Note: Contacts located on back of module are Dry Contacts

only. DO NOT apply any voltage.

6. SENSOR MODULE

The Sensor Module contains the transducer which converts the

pressure/vacuum pressure source into a digital signal that is dis-

played on the display module. The sensor module is housed in a

black ABS plastic fire rated enclosure to reduce the risk of tamper-

ing. Each sensor is clearly labelled and colour coded for the gas or

vacuum being monitored. The sensor module contains a gas spe-

cific DISS fitting to ensure correct connection of the proper sensor to

the respective gas. Each sensor has been factory calibrated for the

specific gas shown on the sensor housing. If it is not connected to

the appropriate gas display module, an error message (E02) will be

displayed.

Alert - 2 Series

Page: 9

AREA ALARM

4. AREA DISPLAY MODULE

The Area Display Module provides a digital display of the actual

pressure/vacuum of a gas being monitored. In addition a gas trend

indicator bar with HIGH and LOW alarms are displayed. The trend

bar has three coloured LED’s: GREEN for Normal condition, YEL-

LOW for Caution condition, and RED for high and low Alarm

conditions.

Each display module contains a gas specific colour coded label

(USA or ISO colours are available). A space is also provided, at the

base of the module, to identify the location that the display module

monitors. The display module is field adjustable for pressure/vacuum

settings, repeat alarm, and units of measure. Whenever the module

is in calibration mode, the bargraph is flashing, indicating the calibra-

tion mode. Dry contacts for high and low alarms are available for

remote monitoring of each module.

5. 2 IN 1 DISPLAY MODULE

The 2 in 1 Display Module provides a digital display of the actual

pressure/vacuum of the gas being monitored. In addition, a gas

trend indicator bar with High and Low alarms are displayed. This

module has two coloured LEDs - green for Normal conditions and

red for High and Low alarm conditions. It is field adjustable for

pressure/vacuum settings, repeat alarms, and units of measure.

Dry contacts for high and low alarms are available for remote

monitoring of each module.

Each module will continuously monitor up to 5 signals from source

equipment or pressure switches. If any of the signals being

monitored go into an alarm condition, a red LED will illuminate and

the audible alarm will sound.

Please Note: Contacts located on back of module are Dry Contacts

only. DO NOT apply any voltage.

6. SENSOR MODULE

The Sensor Module contains the transducer which converts the

pressure/vacuum pressure source into a digital signal that is dis-

played on the display module. The sensor module is housed in a

black ABS plastic fire rated enclosure to reduce the risk of tamper-

ing. Each sensor is clearly labelled and colour coded for the gas or

vacuum being monitored. The sensor module contains a gas spe-

cific DISS fitting to ensure correct connection of the proper sensor to

the respective gas. Each sensor has been factory calibrated for the

specific gas shown on the sensor housing. If it is not connected to

the appropriate gas display module, an error message (E02) will be

displayed.