8 Amico Corporation

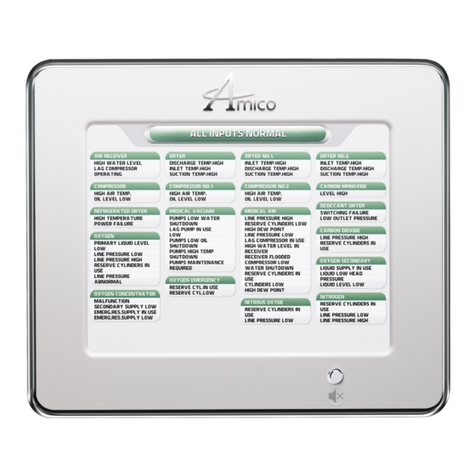

Alert-3 sensor operating pressure range:

Mid Pressure (0 to 99 psi) - Oxygen, Medical Air, Nitrous Oxide, Carbon Dioxide

High Pressure (0 to 249 psi) - Nitrogen, Instrument Air

Vacuum (0 to 30 inHg) - Vacuum, WAGD, AGSS

CAUTION: To protect from static electricity, ensure to discharge body static before installing the Medical Gas

alarm and sensors. Do not ground the sheild drain wire at sensor or inside alarm panel back box.

B: REMOTE (outside the back box)

i. Connect a tee (supplied by others) to the pipeline with a 1/4" NPT female

connection that will accept the DISS Demand Check Valve.

ii. Locate the gas-specific sensor module to be installed.

iii. Thread the DISS Demand Check Valve into the correct gas pipeline.

iv. The sensor module contains a gas-specific DISS fitting. Push the sensor module

hex-nut and nipple adapter into the demand check-valve. With a wrench, tighten

the nut so that it makes a good seal.

v. Marrette in a junction box (supplied by others) the #22 gauge stranded, shielded twisted pair sensor cable to

the installation cable (supplied by others).

vi. In the presence of any electrical, magnetic, radio frequencies, wireless or other interference, cable installation

(supplied by others) running from the junction box (supplied by others) to the alarm MUST be placed in a

metallic conduit.

Installation Guide

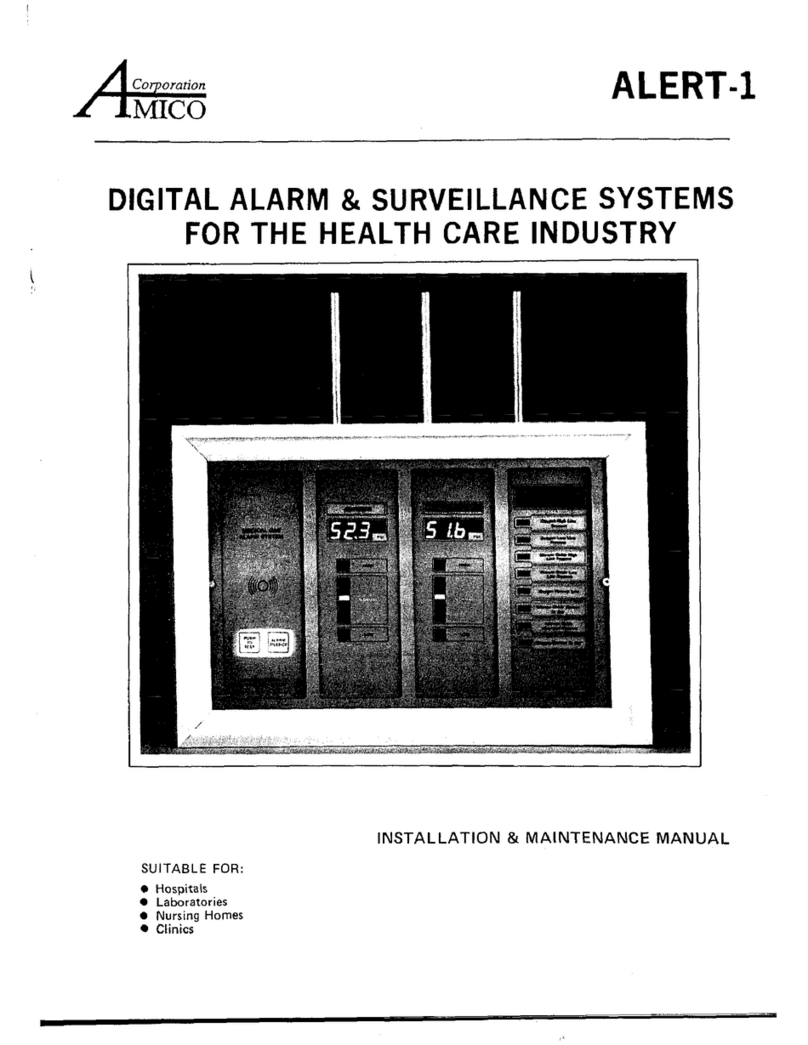

Amico Microprocessor Based Alarm

Page: 12

CAUTION: The microprocessor circuitry on the ALERT-2 alarm con-

tains sophisticated integrated semiconductors. If it becomes necessary

to remove a module, PLEASE hold the boards by the edges. DO NOT

TOUCH any of the components on the board. Static discharge can

cause the modules to malfunction, or become damaged.

SENSOR

LOCAL (In the Back Box)

1. Locate the gas specific

sensor module to be in-

stalled.

2. In the back box, there are

colour coded gas labels

located under the DISS

Demand check valves. Each

label identifies where each

sensor module is to be

placed.

3. The sensor module contains

a gas specific DISS fitting.

Push the sensor module

hex-nut and nipple adapter

up into the demand check-

valve. With a wrench, tighten the nut so that it makes a good seal.

NOTE: Pressure on sensors are not to exceed 250psi

for Pressure sensors and 30” for Vacuum sensors

REMOTE (Outside the Back Box)

1. Connect a Tee (supplied

by others) to the pipeline

with a 1/4" NPT female

connection that will accept

the DISS Demand check-

valve.

2. Locate the gas specific

sensor module to be

installed.

3. Thread the DISS Demand

check-valve into the

correct gas pipe line.

4. The sensor module contains a gas specific DISS fitting. Push the

sensor module hex-nut and nipple adapter up into the demand

check-valve. With a wrench, tighten the nut so that it makes a

good seal.

i. Attach the LCD screen to the back box assembly by using star head

screws (provided with frame in a plastic bag).

STEP 5: FRAME ASSEMBLY

ii. Attach the frame wire with 2 dome head screws (provided with frame

in a plastic bag). This will allow the frame assembly and back box to the

fastened securely together.

iii. Close the LCD screen with a back box by tightening two screws

provided with divider plate.