4Amico Pipeline

User Responsibility

Introduction

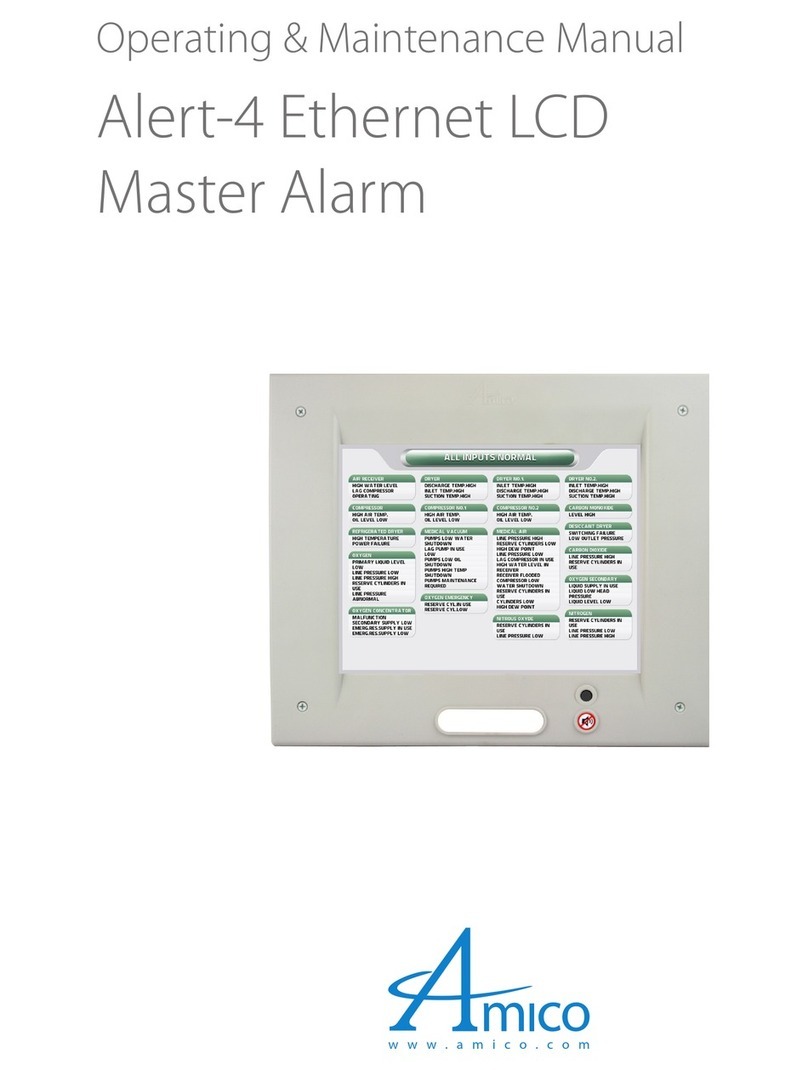

The information contained in this Installation and Operation Maintenance Manual, pertains only to the Alert-3

microprocessor based digital LCD alarm. This product will perform to conformity with the descriptions

contained in this manual, when assembled, operated, maintained and serviced in accordance with the installation

instructions provided.

The alarm must be checked periodically. Parts that are broken, missing, worn, distorted or contaminated,

must be replaced immediately. Should such repair or replacement become necessary, please contact Amico

Corporation or their distributors.

All alarms should not be repaired, or altered without prior written or verbal approval from Amico Corporation

or its distributors. Failure to comply will void all warranty on the alarm.

Statements in this manual preceded by the words WARNING, CAUTION, DANGER and NOTE are of special

signicance. Please read these sections carefully.

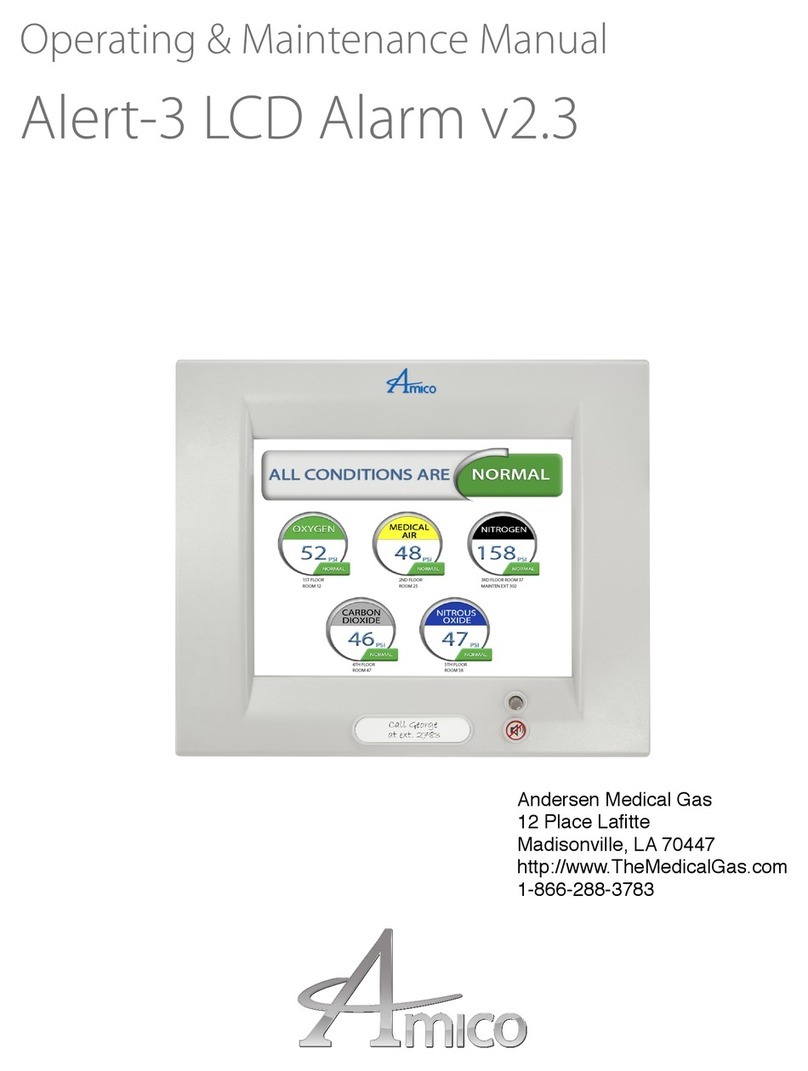

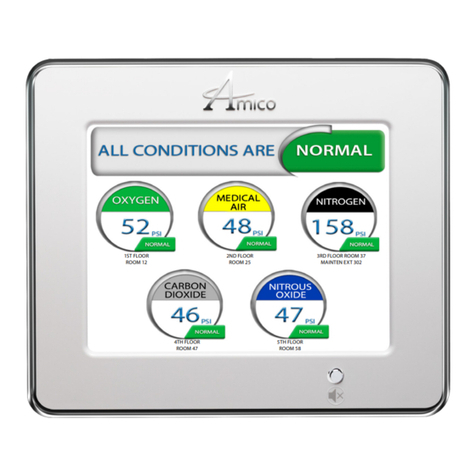

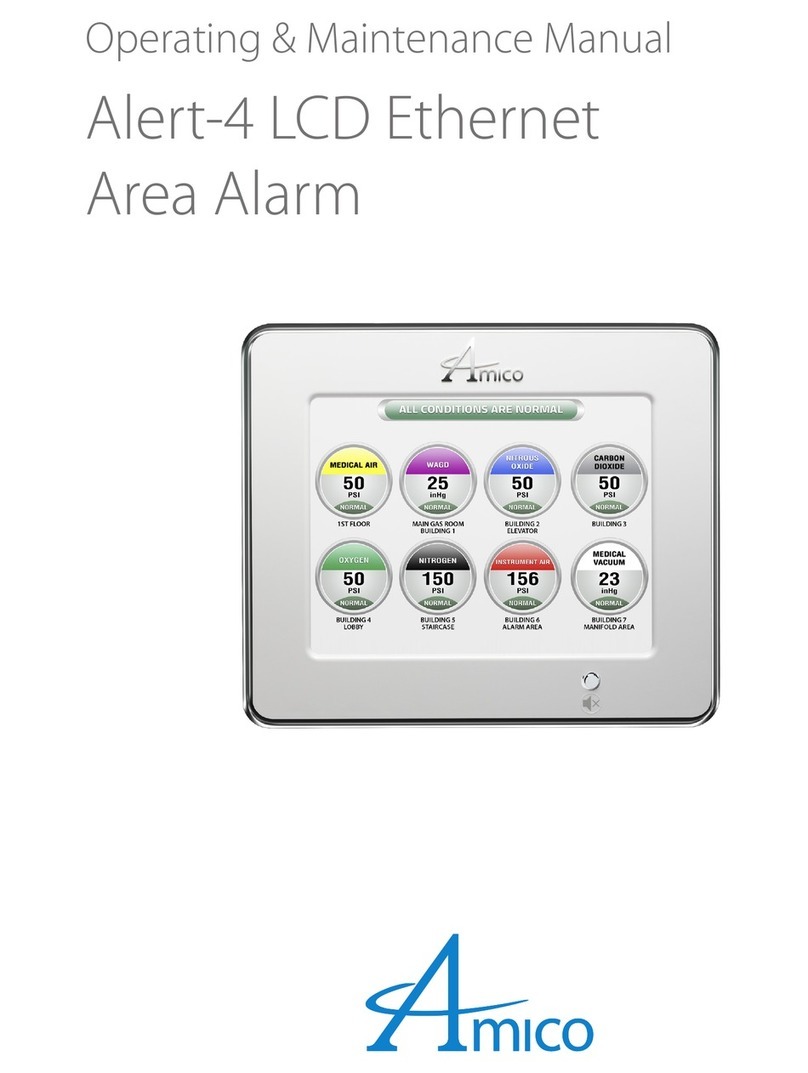

The Amico Medical Gas LCD alarm system (Alert-3) incorporates the latest microprocessor based technology

for alarm and surveillance systems. The alarm has been designed to provide user exibility and reliability. This

manual shall enable the customer to install, use, and maintain the alarm appropriately.

There is one “MUTE” ( ) or “PUSH TO TEST” button located on the front face of the LCD panel. The button

has two functions, to silence an alarm that has occurred, and to view the audible alarm sound level and high and

low set points. When an audible alarm is triggered, press the button to silence the alarm. To view the audible alarm

sound level and high and low set points, press and hold the button for 20 seconds to display the information on the

LCD Alarm screen.

All Gases or Vacuums are displayed on the LCD screen for clear visibility, to facilitate the monitoring function by hospital

personnel. Under normal operation, the gas indicator will be in the GREEN - OK position. If an alarm condition occurs, a RED-

Alarm indicator will be displayed and an audible alarm shall be continuous until silenced by pushing the“MUTE”button.

The LCD Alarm can be connected to a “Building Management System” for a generic alarm indicator.

WARNING: denotes steps which can prevent injury.

CAUTION: denotes steps which can prevent damage

to equipment.

DANGER: denotes steps which can prevent electrical

shock to equipment or to prevent serious injury and/

or death.

Amico Microprocessor Based Alarm

Page: 4

USER RESPONSIBILITY

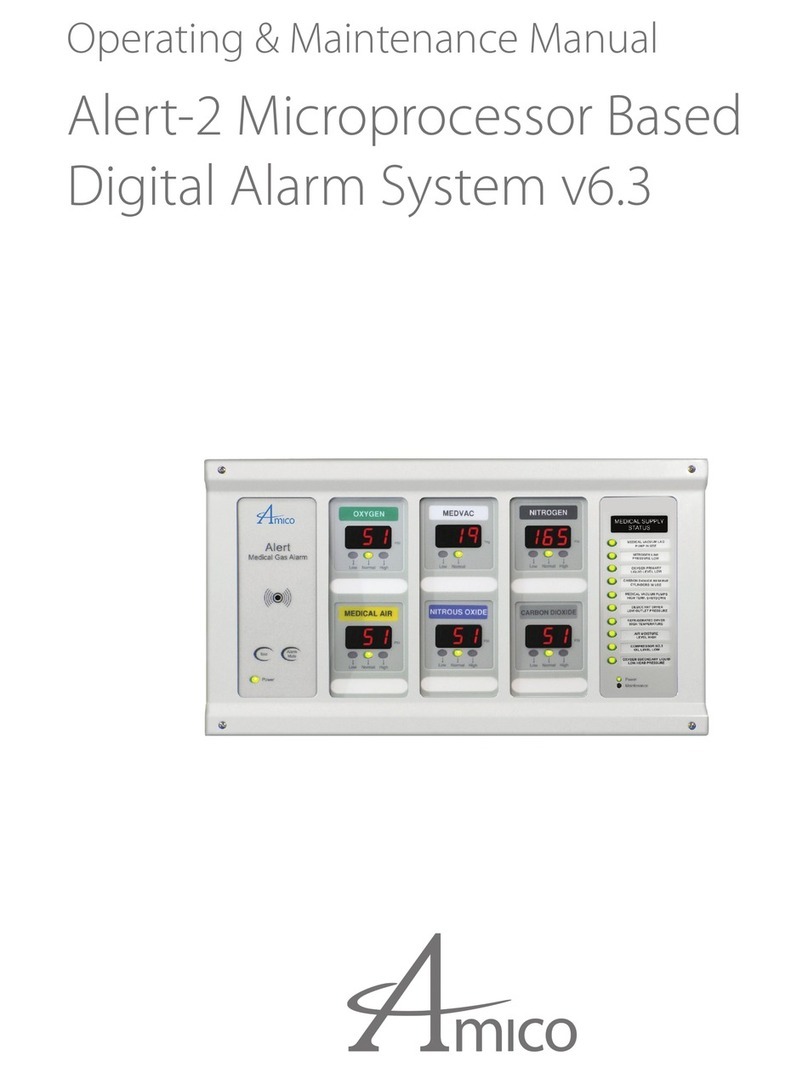

The information contained in this Installation and Operation Maintenance

Manual, pertains only to the ALERT-2 microprocessor based digital alarm.

This product will perform to conformity with the descriptions contained in this

manual, when assembled, operated, maintained and serviced in accordance

with the installation instructions provided.

The alarm must be checked periodically. Parts that are broken, missing,

worn, distorted or contaminated, must be replaced immediately. Should such

repair or replacement become necessary, please contact Amico Corporation

or their distributors.

All alarms should not be repaired, or altered without prior written or verbal

approval of Amico Corporation or it’s distributors. Failure to comply will void

all warranty on the alarm.

Statements in this manual preceded by the words WARNING,CAUTION,

DANGER and NOTE are of special significance. Please read these sections

carefully.

WARNING: denotes steps which can prevent injury.

CAUTION: denotes steps which can prevent damage to equipment.

DANGER: denotes steps which can prevent electrical shock to equipment

or to prevent serious injury and/or death.