AIPQB1215WA61/01

3/36 aipqb1215wa6101_g_en_101

Contents History of revisions.........................................................................................4

Related documentation...................................................................................4

1. Introduction..........................................................................................5

2. Technical parameters..........................................................................6

2.1. Dimensions.....................................................................................................9

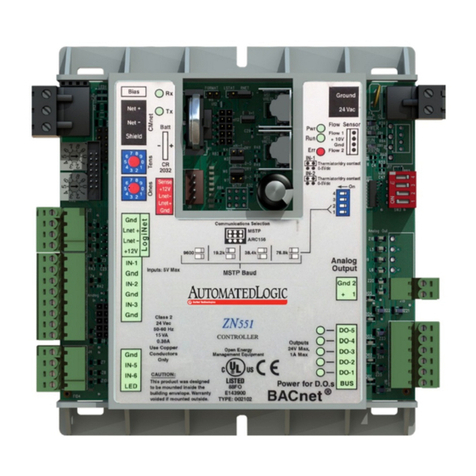

2.2. Connector location..........................................................................................9

2.3. Location of mounting holes...........................................................................10

2.4. Recommended drawing symbol ...................................................................10

2.5. Type label.....................................................................................................11

3. Conformity assessment ....................................................................13

3.1. Other tests....................................................................................................14

4. Power supply......................................................................................15

4.1. Turning TFT panel on and off.......................................................................15

4.1.1 SB input is used............................................................................................16

4.1.2 SB input is not used......................................................................................17

5. Digital inputs / outputs......................................................................18

6. Communication lines and peripherals.............................................20

6.1. RS422 ..........................................................................................................20

6.2. Audio............................................................................................................21

6.3. Ethernet........................................................................................................22

6.4. USB..............................................................................................................23

6.5. Indication LED..............................................................................................24

7. Mounting.............................................................................................25

7.1. Mounting procedure......................................................................................25

7.1.1 Preparing the workplace...............................................................................25

7.1.2 Casing removal.............................................................................................25

7.1.3 Unmounting console.....................................................................................27

7.1.4 Mounting console on the wall .......................................................................28

7.1.5 Connection of cabling...................................................................................28

7.1.6 Mounting display...........................................................................................28

7.1.7 Mounting cover.............................................................................................29

7.2. Mounting claims............................................................................................31

8. Ordering information and completion .............................................32

8.1. Completion ...................................................................................................32

8.2. Connectors...................................................................................................32

9. Packing ...............................................................................................33

10. Storing.................................................................................................34

11. Maintenance .......................................................................................35

12. Waste disposal...................................................................................36