Ampair ® 300 (Mk1, “Pacific”) Wind Turbine Manual

- 2 - © Ampair, April 2007

1INTRODUCTION.................................................................................................................................... 3

1.1 Labelling ........................................................................................................................................... 3

1.2 Applications ...................................................................................................................................... 3

2SAFETY INSTRUCTIONS ..................................................................................................................... 4

2.1 Disclaimer:........................................................................................................................................ 4

2.2 Potential sources of danger.............................................................................................................. 4

3TECHNICAL CHARACTERISTICS........................................................................................................ 7

3.1 Required space ................................................................................................................................ 7

3.2 Technical data .................................................................................................................................. 7

3.3 System description ........................................................................................................................... 8

4INSTALLATION...................................................................................................................................... 9

4.1 Installation sequence........................................................................................................................ 9

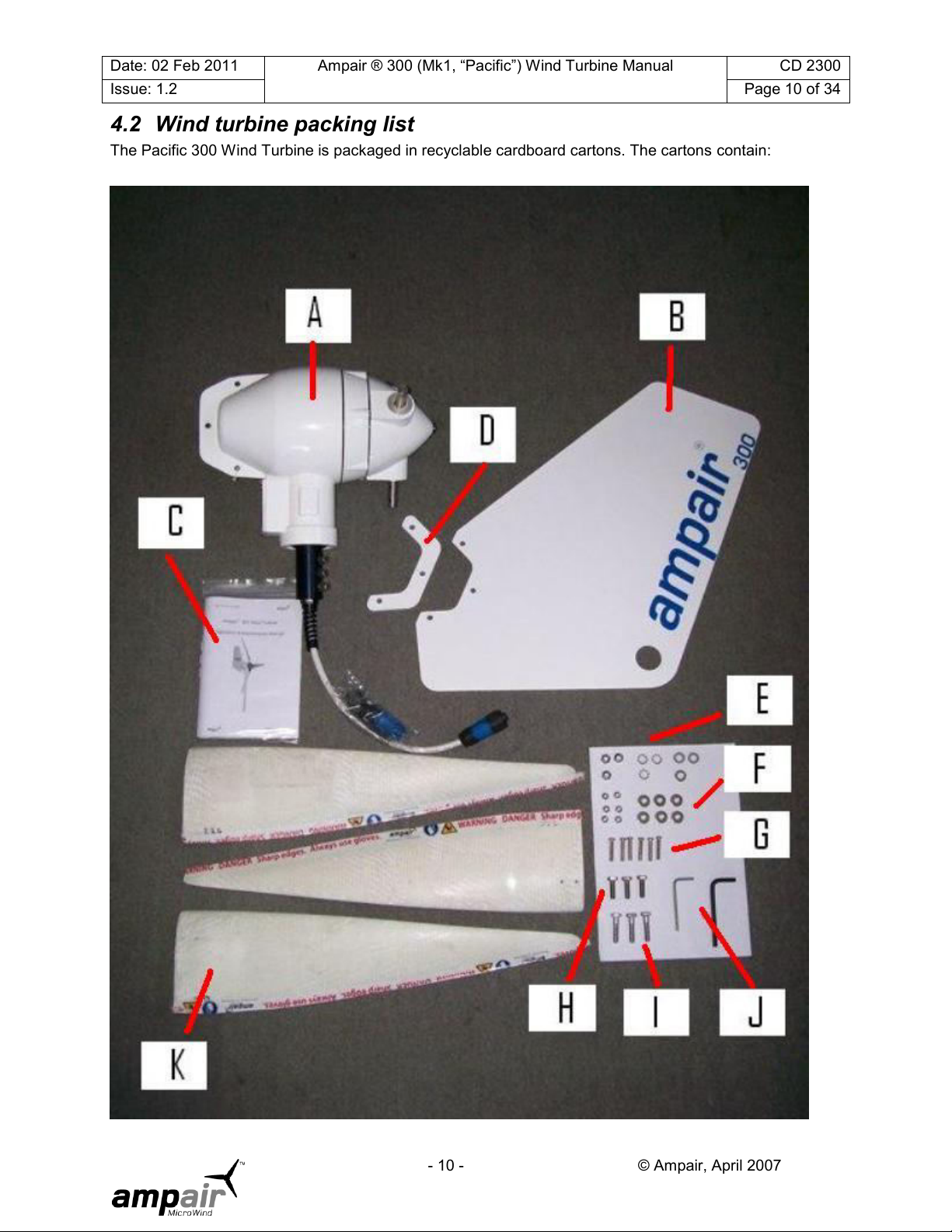

4.2 Wind turbine packing list................................................................................................................. 10

4.3Accessories packing lists................................................................................................................ 11

4.4 Tools ............................................................................................................................................... 12

4.5 Choosing a mounting...................................................................................................................... 13

4.6 Electrical installation ....................................................................................................................... 16

4.7 Electrical components .................................................................................................................... 19

4.8 Final assembly................................................................................................................................ 23

5OPERATION & PERFORMANCE........................................................................................................ 25

5.1 Starting and stopping...................................................................................................................... 25

5.2 Performance ................................................................................................................................... 26

6INSPECTION & MAINTENANCE......................................................................................................... 27

6.1 Major disassembly.......................................................................................................................... 27

6.2 Drawings and component list ......................................................................................................... 31

6.3 Recommended spares ................................................................................................................... 33

7WARRANTY......................................................................................................................................... 33

8SERVICING, REPAIRS, & DISPOSAL ................................................................................................ 33

Disclaimer:

The information in this manual is believed to be correct and reliable. However Ampair assumes no

responsibility for inaccuracies and omissions. The user of this information and product assumes full

responsibility and risk.

All specifications are subject to change without notice.

Wind turbines, electrical power and battery systems, and wind turbine mounting systems are all capable of

causing death or serious injury or fire if incorrectly installed, operated, or maintained. If in doubt, ensure

that all activities are carried out by trained and competent personnel.