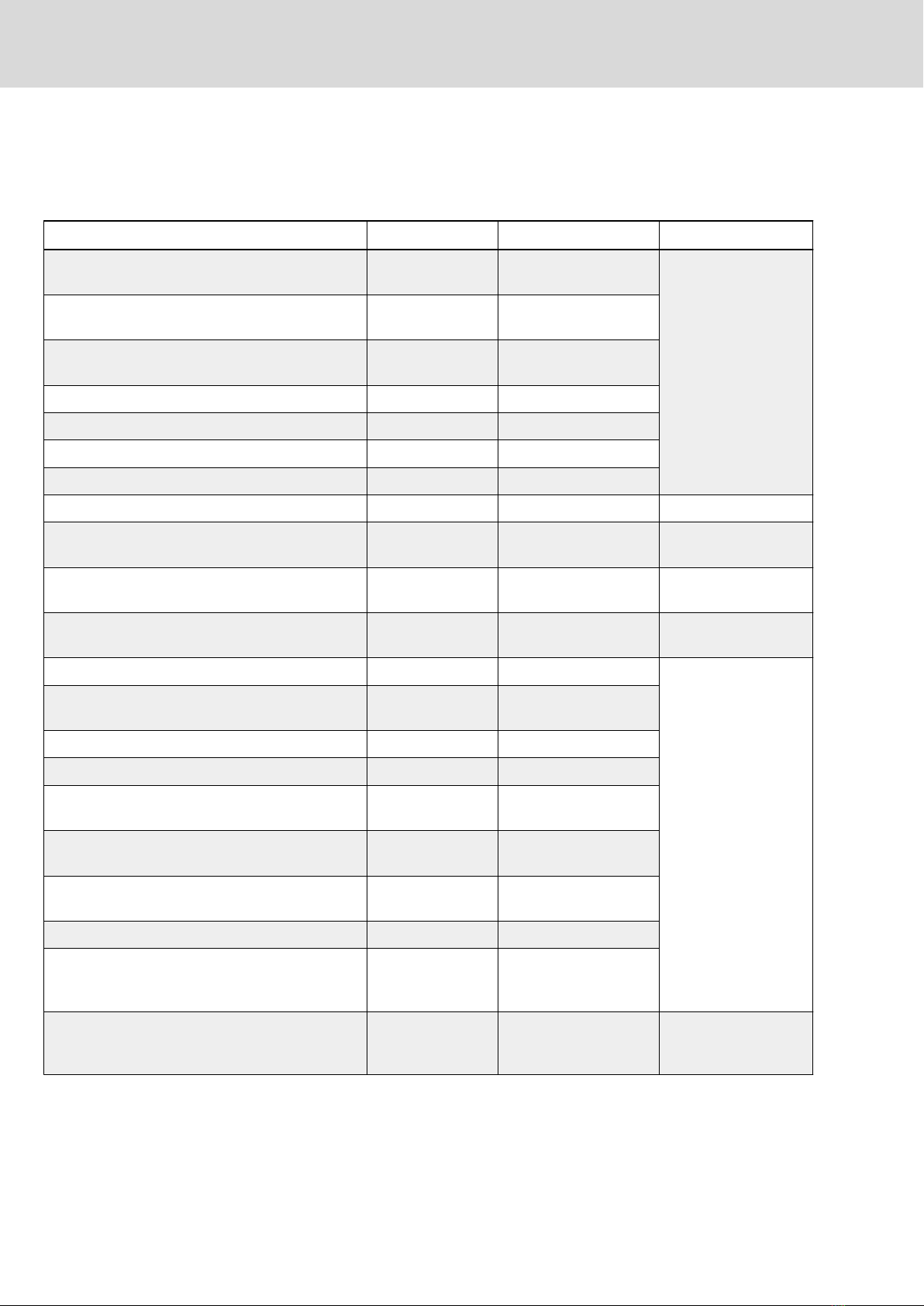

Page

7.2.6 Starting with FcP 5020 dialog............................................................................................................ 68

7.2.7 Converter I/O Configuration............................................................................................................... 71

Analog Input AI1............................................................................................................................. 71

Quick Configuration For Rexroth HM20 Pressure Sensor.............................................................. 74

Analog Input AI2............................................................................................................................. 76

Analog Output AO1........................................................................................................................ 77

Digital Input..................................................................................................................................... 78

Digital and Relay Output................................................................................................................. 79

7.2.8 Quick Configuration For Rexroth MOT-FC_HOY Motor ................................................................... 80

7.2.9 First Commissioning.......................................................................................................................... 83

7.3 Commissioning (advanced).................................................................................................................. 85

7.3.1 Overview of Main Functions.............................................................................................................. 85

7.3.2 pQ Controller Parameter Setting....................................................................................................... 87

Overview and introduction.............................................................................................................. 87

7.3.3 Enhanced Parameter Setting............................................................................................................ 94

Overview and introduction.............................................................................................................. 94

Easy command setting: internal parameter, selectable pressure command.................................. 94

Control parameter selection: free selectable parameter sets (2 sets)............................................ 95

Switching integral time Ti................................................................................................................ 96

Minimum flow and minimum pressure............................................................................................ 97

7.4 Extension Functions............................................................................................................................. 98

7.4.1 Pump Extended Function.................................................................................................................. 98

7.4.2 Master / Slave Function..................................................................................................................... 99

7.4.3 Sleep / Wake Function.................................................................................................................... 101

7.4.4 Two Points / Double Pump Control................................................................................................. 103

7.4.5 Pressure Drop / Overshoot Compensation...................................................................................... 105

7.4.6 Pump Power Limitation.................................................................................................................... 106

7.4.7 Hydraulic Soft Start and Separate Acceleration Ramp.................................................................... 107

7.5 Protection Function............................................................................................................................. 108

7.5.1 Condition Monitoring and Protection............................................................................................... 108

7.5.2 Overview.......................................................................................................................................... 109

7.5.3 Pressure Sensor Failure Detection.................................................................................................. 109

7.5.4 Actual Pressure Monitoring............................................................................................................. 112

7.5.5 Oil Change Warning / Error Function.............................................................................................. 113

7.5.6 Pressure and Flow Command Limit................................................................................................ 114

7.5.7 Pump Thermal Protection................................................................................................................ 115

7.5.8 Sensor Monitoring........................................................................................................................... 116

7.6 CytroPac Configuration....................................................................................................................... 117

7.6.1 Overview.......................................................................................................................................... 117

7.6.2 Load CytroPac Configuration.......................................................................................................... 117

7.6.3 CytroPac Sensor Monitoring ........................................................................................................... 117

7.6.4 LED Flash Showing Converter Status............................................................................................. 118

7.7 myCro Configuration........................................................................................................................... 119

7.7.1 Overview.......................................................................................................................................... 119

7.7.2 Load myCro Configuration............................................................................................................... 119

7.7.3 myCro Function Description............................................................................................................ 123

DOK-SYTROX-FCP5020****-IT01-EN-P Bosch Rexroth AG III/201

Frequency-controlled pump drive system Sytronix FcP 5020

Table of Contents