8

Connection

1. Connect the Power Supply to the load before

connecting the AC mains.

2. Connect the Power Supply to the AC mains. The AC

LED should illuminate. This indicates that the Power

Supply is receiving power from the AC mains and

that the internal power supply is running.

3. The unit should turn on automatically and the power

switch will illuminate. Press the power switch if you

want to turn the Power Supply OFF.

Operation of the PWI320 Power Supply is very simple. It is intended to operate fully

unattended, and will attempt to recover from any fault, such as Power Supply Over-

Temperature, Insufcient Input Voltage, Output Overload, Output Short Circuit, Power Failure

and more.

Connect the Power Supply to a source of AC power. Conrm that the “AC” LED IS illuminated

(Green). The Power Supply should automatically turn on. If it does not, press the Power button

on the front panel.

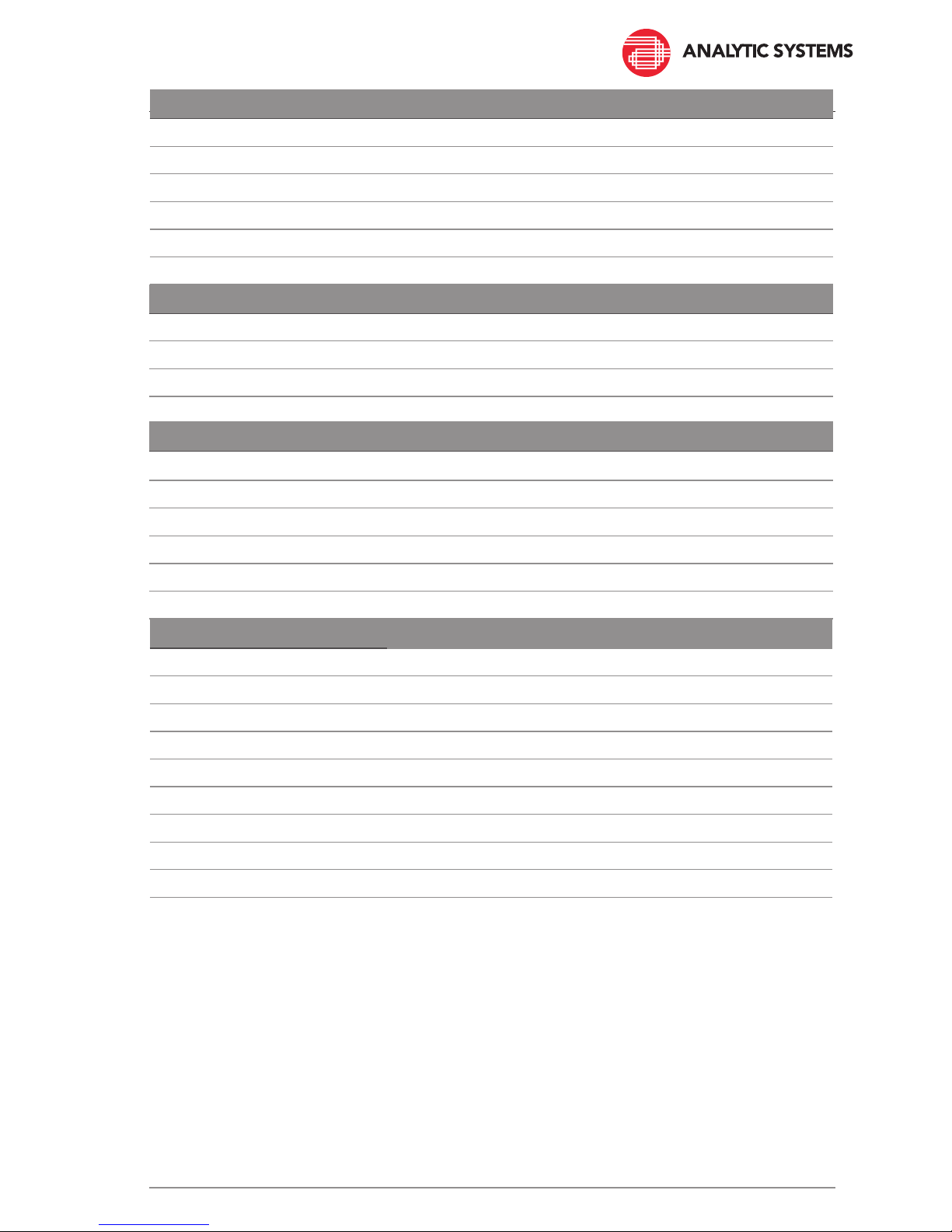

The Power Supply will go through a startup sequence that consists of turning the 6 LEDs

controlled by the computer all Red, then all Green. The Power button will illuminate once the

Power Supply has completely turned on.

If the AC power fails or is disconnected, the Power Supply will resume operation when AC is

restored.

The PWI320 Power Supply is so efcient that is does not need a cooling fan to operate at

maximum performance. However, in a very hot ambient environment the microprocessor

will reduce power output as needed to keep the circuitry operating at a safe and reliable

temperature. In extreme cases, the Power Supply may shut off completely until it cools

sufciently to resume operation.

Operation

INSTALLATION INDICATORS

AC TEMP

25

DEV

75

SVC

FLT

LO V

50

AC PRESENT

PS

The PRG and SEL buttons on the front panel currently have no function. However, in a future

rmware update they will add the capability to adjust the output voltage over a range from

nominal to +17% (-0V to +2V for a 12V model for example). Subscribe to our newsletter to be

notied when this update becomes available.

Front Panel Adjustments