- 3 -

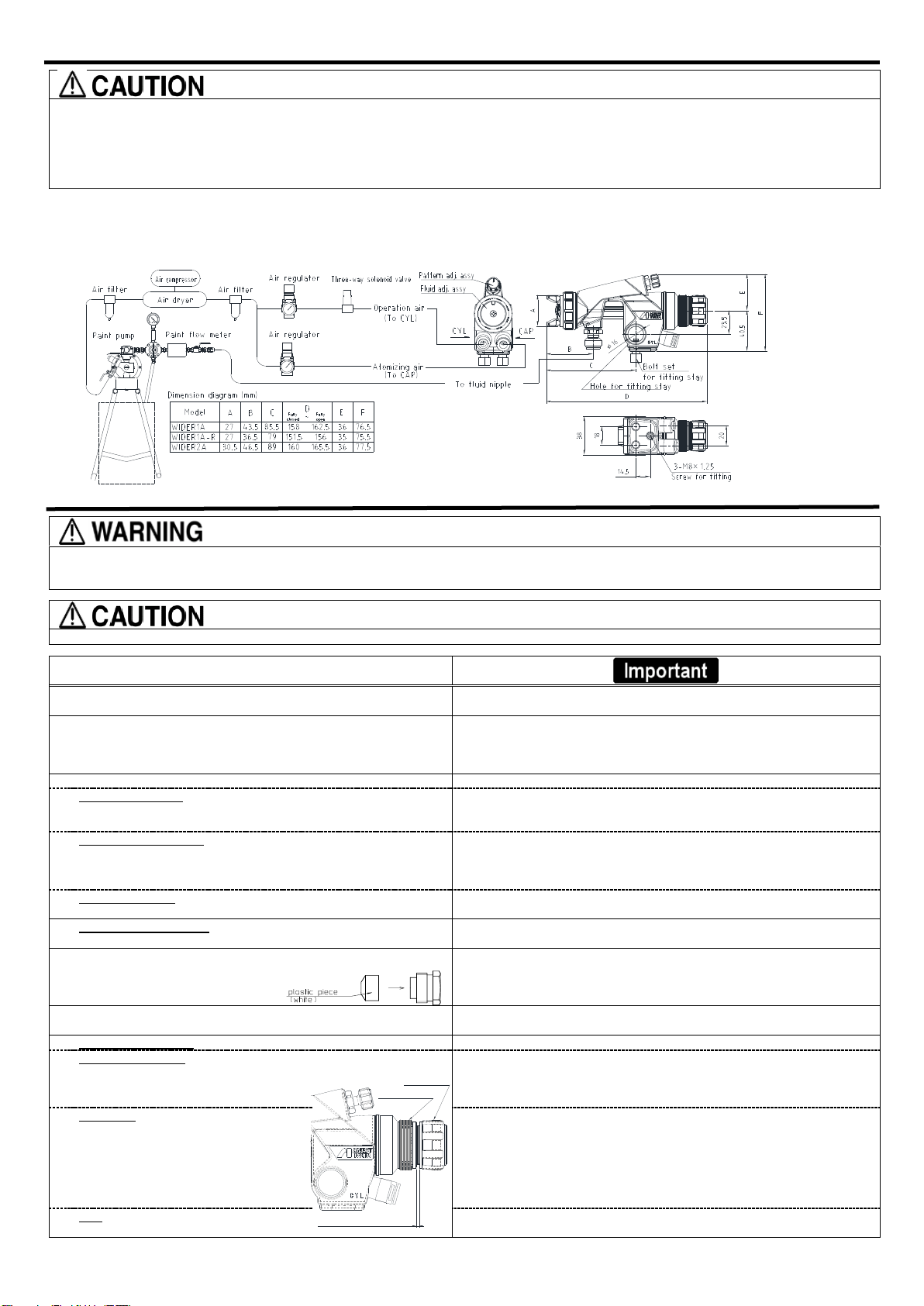

How to connect

Step1

Fit the gun to fitting stay, aim at spraying direction and fix it.

Step2

Connect atomizing air hose to atomizing air side (Cap marked side) and operating air hose to operating air side( CYL marked side).

Step3

Connect fluid hose to fluid inlet side.

Step4

supply thinner to automatic gun. Spray and clean fluid passage with thinner.

Step5

supply paint to automatic gun and test spray and adjust air volume, fluid output and pattern width as necessary.

Maintenance and inspection

Use clean air filtered through air dryer and air filter. ・・・If not, dirty air can cause painting failure.

If you use this gun for the first time after purchasing, clean fluid passages spraying thinner and remove rust preventive oil.

If not, remaining preventive oil can cause painting failure such as fish eyes.

Use three-way solenoid valve of more than φ4 inner dia. cross-sectional area and air hose of overφ6 inner dia. and less than 10m length.

If not, small dia. of solenoid valve and longer air hose between three-way solenoid valve and gun can cause delay in operation.

Firmly fix hose to spray gun.・・・If not, disconnection of hose and drop of container can cause bodily injury.

First release air and pressure fully according to item No. 3 of “Improper use of equipment” of WARNING on page 2.

Only an experienced person who is fully knowledgeable of the equipment should perform maintenance and inspection.

Use neutral cleaner: pH value shall be 6 to 8, otherwise could cause corrosion.

Only use genuine ANEST IWATA parts for any maintenance or repairs.

Pour remainingpainttoanothercontainer. Cleanfluidpassagesand aircap assy.

Sprayasmallamountof thinner into fluid passagesto cleanthem.

Incompletecleaningcanresultin poorspraypatternandcontaminated paint.

Itisespeciallyimportant cleanthegunfullyandpromptlyafter usingtwo-componentpaint.

Clean eachsection withbrushsoakedwith thinnerandwipe outwithwastecloth.

Soaking whole spray gun in solvent may cause spraygun malfunction.Also soaking air cap assy. itself

forextendedperiodmay causeadefective spraypattern.

When cleaning,never scratchtheaircapassy., fluid nozzle,orfluidneedle.

Avoid touchingordamaging thetip ofthe fluidnozzleorneedle.

Beforedisassembly,fully cleanfluidpassages.

Duringdisassembly,donotscratch seatsection.

Disassemblefluidnozzle.

Useringspanner,boxwrenchoroptionalexclusivespanner(code No.035386000)

to disassemblefluid nozzle.

Remove fluid nozzle after removing fluid needle set or while keeping fluid needle pulled, in order to

protectseatsection.

Disassemblefluidneedleassy

Remove fluidadj. setandpulloutfluid needlesetfromgunbody.

Payattention so that spring does not suddenly fly outsince fluid adj. set is strongly pushedby fluid

needlespringandpiston spring.

Pull fluidneedle setafterloosening fluid needlepacking settoprotectfluid needlepacking set.

Disassemblepistonset

Screwrear sectionof fluidneedle setinto pistonand pullout pistonset.

Be carefulnot todamagepistonpackingwhen pullingoutpistonset.

Disassemblearivalveseatassy

Useacommerciallyavailableboxwrench(14mm).

Be carefulnotto damageOringand seatsection whendisassembleairvalveseatassy.

When you want to adjust fluid needle packing set, first tighten it by hand while fluid needle set

remainsinserted.Then tightenit further about1/6turn (60-degree) byspanner.

When you removeneedle packing set,donotleave

plastic pieceofneedlepackingsetin thegunbody

If youtightenfluid needlepacking settoomuch,fluid needle setwillnotmovesmoothly,resulting inpaint

leakage from tip of fluid nozzle. Try to adjust it carefully while pulling piston and confirming movement of

fluid needleset.

When you tightenit toomuch, firstfullyloosenit and then tighten itagain carefully.

Turn pattern adj. knob counterclockwise to fully open. And then tighten pattern adj.guide into gun

body.

Iffluid adj.setisnot fully opened,tipofit cancontactanddamagetipofgunbodysetand causeseizure

of thread.

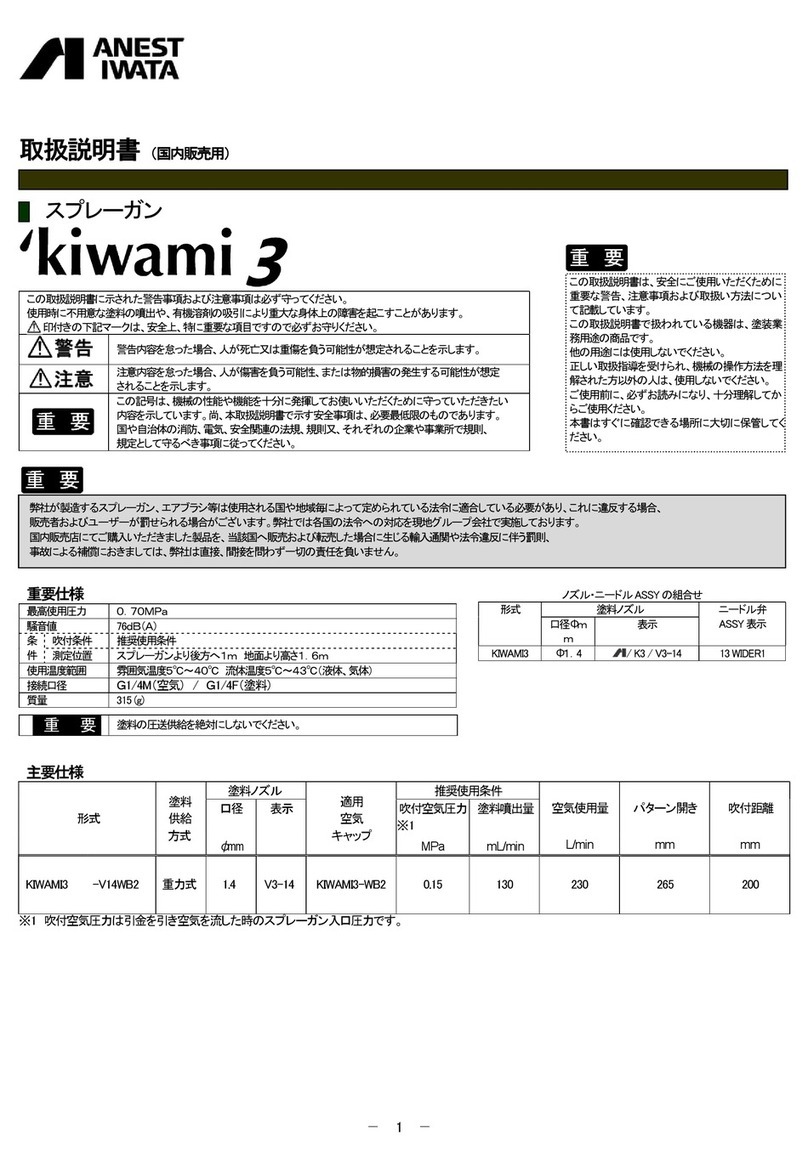

Noteson theFluid adj.assy.

Howto installon thebody

To assemble the Fluid adj. assy, open the Fluid adj. assy

fullyand applysilicone-freegreaseoroilto thethreads.

To install/removetheFluidadj.assy,turnthe knurledpart.

If fluid adj. set is not fully opened, tip seat section of it can contact and damage fluid nozzle and cause

seizure ofthread.

Howtoadjust

To adjust the Fluid adj. assy, turn the groove on the knob

part.

The standard for fully closing the paintadjustment device is

thatthe gap between the guide and the knob is WIDER1A:

2mm,WIDER2A:1 mm:WIDER2A:1mm.

Do notovertighten.

Ifyou over-tighten,the nozzle will bedeformed.

Other

Do notdisassemble theFluid adj.assy.

Ifyou disassembleit,youmaynotbeable toreassemble itdue tolossofparts.

knurled part

knob part

Distance between guide and knob