- 2 -

■

Safety precautions

1. Spark and open flames are strictly prohibited.

Paints can be highly flammable andcan cause fire.

void any ignition sources suchas smoking, open flames,electrical goods, etc.

2. Never use the following HALGOGENATED HYDROCARBON SOLVENTS

which can cause cracks or dissolution on gun body (aluminum) by chemical

reaction.

3. Securely ground spray gun.

Use airhose withbuilt-in groundwire oruse groundedgun stay.

Groundresistance :Less than 1MΩ.

Check the earth stability periodically.

If not, insufficient grounding can cause fire and

explosion due to static electricsparking.

・unsuitablesolvents:methylchloride,dichloromethane,1.2-dichloroethane,carbon tetrachloride,,trichloroethylene,1.1.1-trichloroethane

(Besurethat allfluids andsolvents arecompatiblewith gunparts. Weareready tosupply amaterial listusedin theproduct)

1. Never point gun toward people oranimal.

If done, it can cause inflammation of eyes and

skin or bodily injury.

2. Never exceed maximum operating pressure

andmaximum operating Temperature.

3. Be sure to release air and fluid pressures before cleaning,

disassembling or servicing.

If not, remaining pressurecan cause bodily injury due to improper

operationor scatteringcleaning liquid.

Inorder torelease pressure,firststopsupplyofcompressedair, fluidand

thinnerto automaticspray gun.

Next, supply only piston operating air and exhaust fluid by operating fluid

needle, which results in automatic supply stop of allcompressed air.

4. Tip of fluid needle set has a sharppoint. .

Do not touch the tip of needle valve at the maintenance for the protection

ofthe humanbody.

Protection of human body

1.Use in a well-ventilated site by using spray booth.

Ifnot, poorventilation cancause organicsolvent poisoningand catch fire.

2.Always wear protective gear (safety glasses, mask, gloves).

If not, cleaning liquid,etc., can cause inflammation ofeyes and skin.

If you feel something wrongwith eyes or skin, immediately see a doctor.

3.Wear earplugs if necessary.

Noiselevelcan exceed 80dB(A), depending onoperating conditions and painting site

Other precautions

1.Never alter this spray gun.

Ifdone, itcan causeinsufficient performanceand failure.

2.Enter working areas of other equipment (robots, reciprocators, etc.) after

machines are turned off. Ifnot, contactwith themcancauseinjury.

3.Never spray foods or chemicals through this gun.

If done, it can cause accident by corrosion of fluid passages or adversely

affecthealth bymixed foreignmatter.

4.If something goes wrong, immediately stop operation and find the

cause. Do not use again until you have solved the problem.

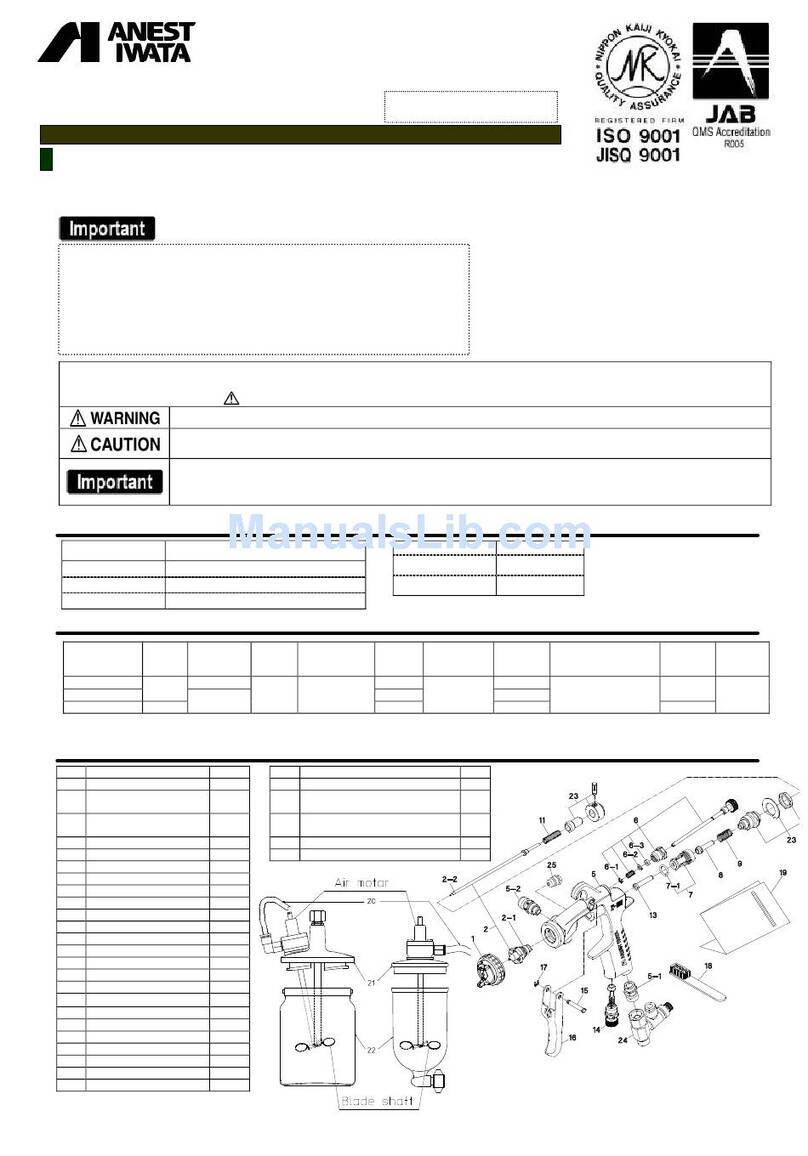

■

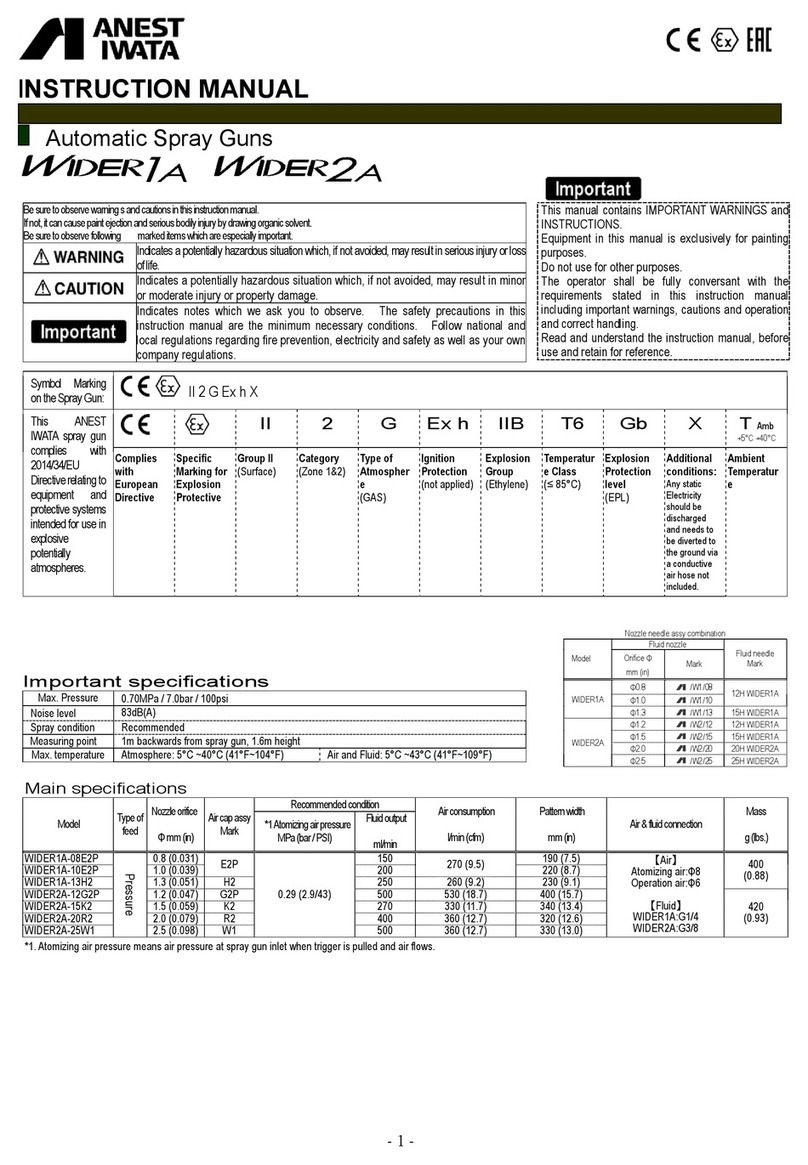

How to connect

-Use clean air filtered through air dryer and air filter. ・・・If not, dirtyair cancause painting failure.

-If you use this gun for thefirst time after purchasing, clean fluid passages sprayingthinner and remove rust preventive oil.

If not, remaining preventive oil can cause painting failure such as fish eyes.

-Use three-way solenoid valve of more than φ4 inner dia. cross-sectional area and air hose of overφ6 inner dia. and less than 10m length.

If not, small dia.of solenoid valve and longerair hose between three-way solenoid valve and gun can cause delay inoperation.

-Firmly fix hoseto spray gun.・・・If not, disconnection of hose and drop ofcontainer can cause bodily injury.

Job1.Fit the gunon a standor fitting stay,aimat sprayingdirectionandsecureit firmly

withfixingbolts.

Job2.Connectatomizingairhoseto atomizingair inlet (Capmarkedside)andfan air

hoseto fan air inlet(FAN markedside)tightly.

Andthen connectoperatingairhosetooperating airhoseto operatingairinlet

(CYL markedside)tightly.

Job3.Connectfluidhose tofluidinlet tightly.

Job4.Supplythinnertoautomaticgun.Sprayandcleanfluidpassagewiththinner.

Job5.Supplypaint toautomaticgunand testspray andadjustair volume,fluidoutputand

patternwidthasnecessary.

[Connecting example ]

Fire andex

losion

Improperuseofequipment