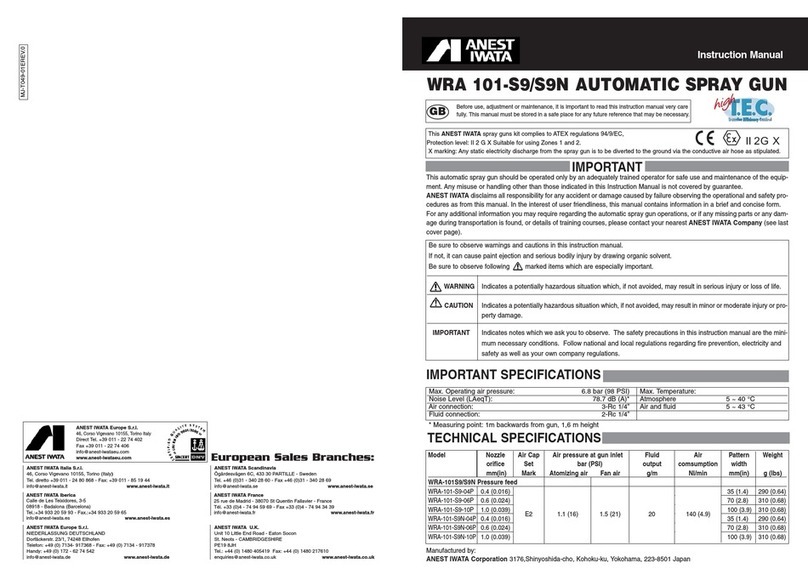

-3-

■

How to connect

・Use clean air filtered through air dryer and air filter. ······ If not, dirty air can cause painting failure.

・If you use this spray gunfor the first time after purchasing, clean fluid passages spraying thinner and remove rust preventive oil.

If not, remaining rust preventive oil can cause painting failure such as fish eyes.

・Firmly fix hose or container to spray gun. ······ If not, disconnection of hose and drop of container can cause bodily injury.

Job1. Connect an air hose to air nipple tightly.

Job2. Connect a fluid hose or a container to fluid nipple tightly.

Job3. Flush the spray gun fluid passage with a compatible solvent.

Job4. Pour paint into container, test spray and adjust fluid output as well as pattern width.

■

Maintenance and inspection

・First release air and pressure fully according to item No. 3 of “Improper use of equipment”of WARNING on page 2.

・Only an experienced person who is fully conversant with the equipment can do maintenance and inspection.

・Use neutral cleaner: pH value shall be 6 to 8, otherwise could cause corrosion.

・Never use commercial or other parts instead of ANEST IWATA original spareparts.

Step-by-step procedure

1. Pour remaining paint to another container. Clean fluid passages andair cap assy.

Spray a small amount of thinner to clean fluid passages.

1. Incomplete cleaning can fail pattern shape and uniform particles.

Especially clean fully and promptly two-component paint after use.

2. Clean each section with brush soaked with thinner and wipe out with waste cloth.

2. Soaking whole spray gun in solvent may cause spray gun malfunction. Also soaking air

cap assyitself for extended periodmay cause defective pattern.

When cleaning, never scratch each hole of air cap assy, fluid nozzle, and fluid needle

assy.

Never damage the tip of fluid nozzle or must not put your hand on it.

3. Before disassembly, fully clean fluid passages.

Disassemble fluid nozzle.

Use ring spanner, box wrench or optional exclusive spanner (code 93538601)

to remove fluid nozzle.

3. During disassembly, do not scratch seat section.

Remove fluid nozzle after removing fluid needle assy or while keeping fluid needle pulled,

in order to protect seat section.

4. When you want to adjust fluid needle packing set, first tighten it by hand while fluid needle

assyremains inserted. Then tighten it further about 1/6 turn (60-degree) by spanner.

When you remove needle packing set, do not leave plastic piece of needle packing set in

the spray gunbody.

4. If you tighten fluid needle packing set too much, fluid needle assy will not move smoothly,

resulting in paint leakage from tip of fluid nozzle. Try to adjust it carefully while pulling

trigger and confirming movement of fluid needle assy.

When you tightenit too much, first fully loosen it and then tighten it again carefully.

5. In order to assemble air valve, first assemble air valve & air valve spring & fluid adj. guide

assy together. Next, insert fluid needle assy into fluid adj. guide assy, then fit it to spray gun

body set and screw fluid adj. guide assy.

5. If you try to fit air valve spring and air valve to spray gun body set without fluid needle

assy, air valve will not be fitted correctly and lop packing inside fluid adj. guide assy will

be damaged.

6. Turn pattern adj. knob or air adj. knob counterclockwise to fully open. And then tighten

pattern adj. assy or air adj. assy.

6. Ifpattern adj. knob or air adj. knob isnot fully opened, tip of it can contact and damage of

seat section.

Parts replacement standard

1. Each hole passage of air cap assyand fluid nozzle Replace if it is crushed or deformed.

2. Packing and O ring Replace if it is deformed or worn out.

3. Leakage from seat section between fluid nozzle and fluid needle assy Replace them if leakage does not stop after fully cleaning fluid nozzle and fluid needle

assy.

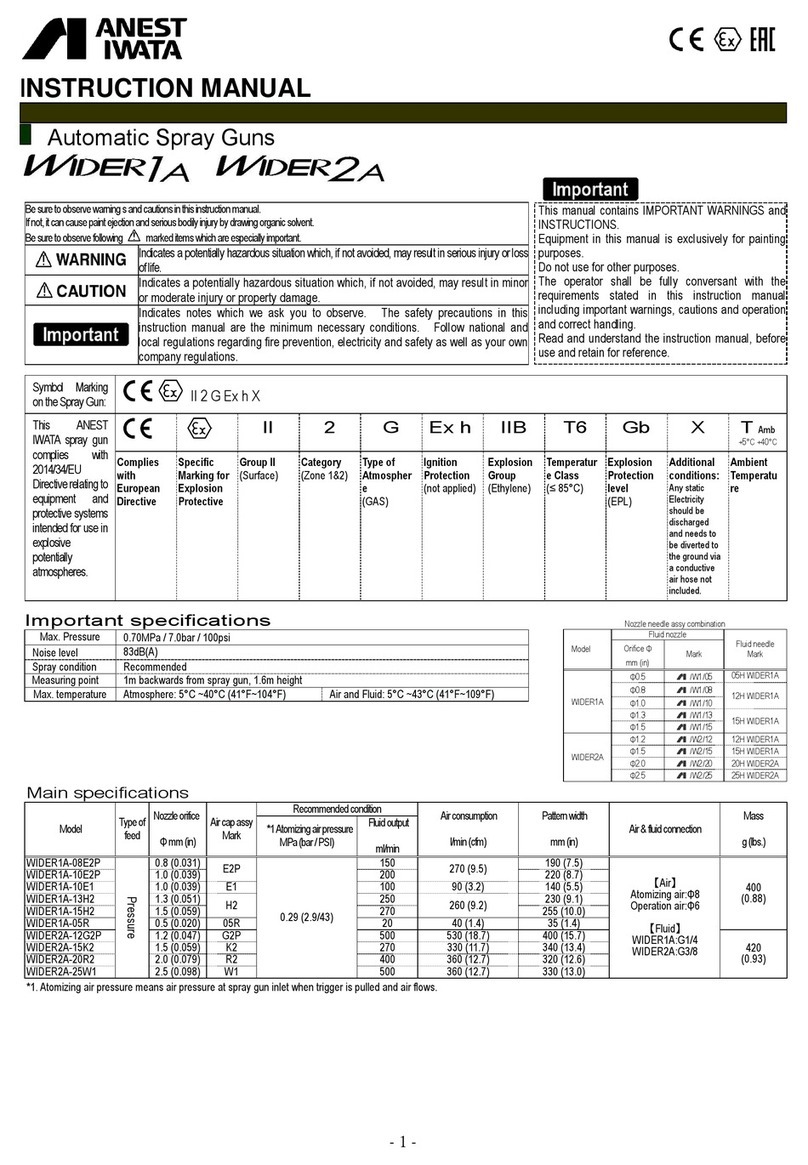

Fluid (Gravity)

(Suction/ Pressure)

Air