- 3 -

■

How to operate

Recommended paint viscosity differsaccording to paint property and

painting conditions. 12 to 20 sec./Fordcup#4isrecommendable.

Keep fluid output as small as possible to the extent that the job will

not be hindered. It will lead to better finishing with fine atomization.

Set the spray distance from the gun to the work piece as near as

possible within the range of 50-150mm(2~5.9 in) As this gun is

operated at low air pressure,high transfer efficiency will not be obtained

ifthe spraydistanceistoo far.

■

Maintenance

and inspection

-First release air and pressure fully according to item No. 3 of “Improper use of equipment” of WARNING on page 2.

-Tip of fluid needle set has a sharp point. Do not touch the tip of needle valve at the maintenance for protection of the human body.

-Be careful not to damage the tip offluid nozzle or must not put your hand on it.

-Only an experienced person who is fully conversant with the equipment can do maintenance and inspection.

-Never use commercial or other partsinstead of ANEST IWATA original spare parts.

-Never immerse the whole gun into liquid such as thinner.

-Never damage holes of air cap a fluid nozzle and fluid needle.

Step-by-step procedure Important

1.Pourremaining paintto another container. Cleanfluid passagesandair capset..

Spraya small amount of thinnerto clean fluid passages. 1. Incomplete cleaning can failpattern shape and uniform particles.

Especially clean fullyand promptly two-component paint after use.

2.Clean each section with brush soakedwith thinnerand wipe outwith wastecloth.

2. Do not immerse the whole gun in thinner. If done, it can damage parts.

Whencleaning,neverscratcheachholeofaircap setandfluidnozzle,andfluidneedleset.

3. Before disassembly, fully clean fluid passages. 3. During disassembly, do not scratch seat section.

(1)Disassemblefluidnozzle.

(1)Remove fluid nozzle after removing fluid needle set or while keepingfluid needle pulled, in

order to protect seat section.

(2)Disassemblefluidneedleset.

You do not need to remove fluid adj. guide set from gun body. Remove fluid adj. knob

and fluid needle spring, and then pull out fluid needle spring, and then pull out fluid

needle set from back of fluidadj. guide set..

(2) Becareful when handing tipof fluid needle set since it is sharp.

Disassemble fluid adj. guide set as little aspossible.

4.To adjust fluid needle packing set, while keeping fluid needle set inserted, tighten fluid

needlepackingseatby hand andthen tightenfurtherbyspanner. 4.Too much tightening of fluid needle packing set can cause bad movement of fluid needle set

andfluidleakagefromthetip of fluidneedleset..

5.In order to assemble air valve, first assemble air valve & air valve spring & fluid adj.

guide set together. Next, insert fluid needle set into fluid adj. guide set , then fit it to

gun bodyset and screw fluid adj. guide set.

5. If you try to fit air valve spring and air valve to gun body set without fluid needle set, air

valve will not be fitted correctly and lop packing inside fluid adj. guide set will be

damaged.

6.Turn pattern adj. knob or air adj. knob counterclockwise to fully open. And then

tightenpatternadj. setor air adj.set.. 6. If pattern adj. Knob or air adj. Knob is not fully opened, tip of it can contact and damage

fluidnozzleand causeseizureof thread.

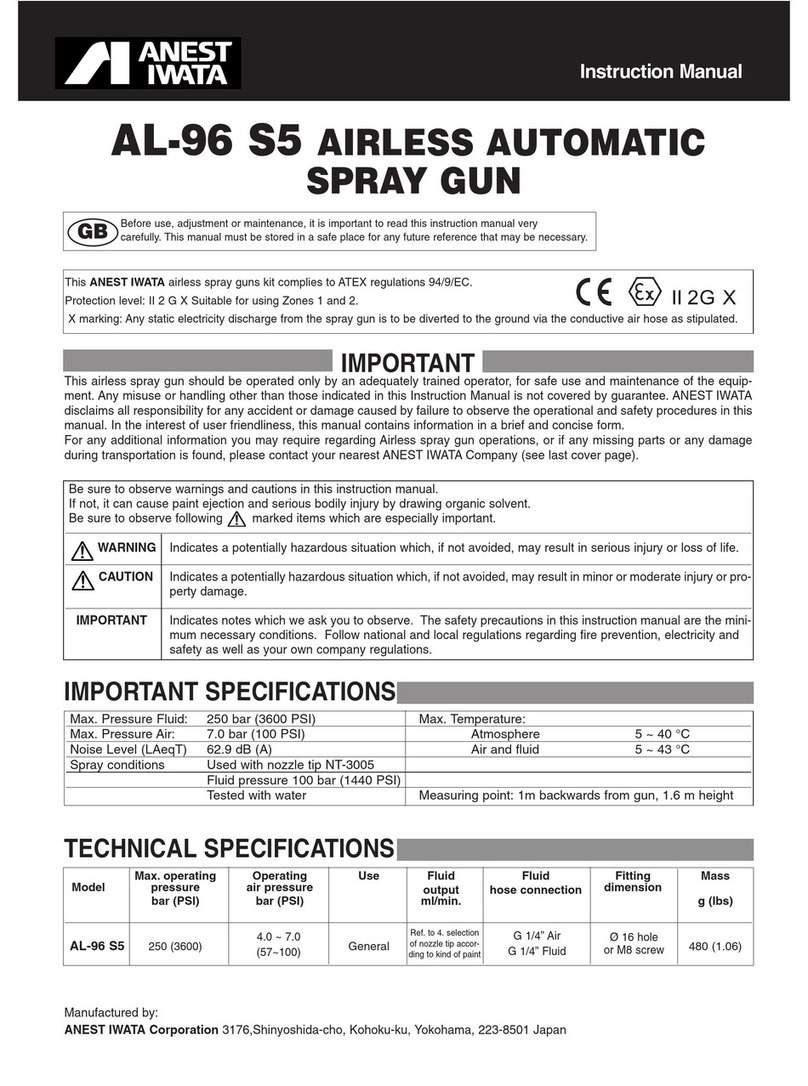

Whereto inspect Partsreplacementstandard

1. Eachhole passage of aircap and fluid nozzle Replace if it is crushed or deformed.

2. Packing and O ring Replace if itis deformedorworn out.

3.Leakage from seat section between fluid nozzle and fluid needle set Replacethemif leakagedoesnotstop afterfullycleaning fluid nozzle and fluid needle set.

If you replace fluid nozzle or fluid needle set only, fully match them and confirm that there is

no leakage.

■

Parts list

When ordering parts,specifygun’s model, part name with ref. No. and markedNo. of aircap

set, fluid nozzle and fluid needle.

Whenreplacingfluidnozzleor/and fluidneedlefor pressurefeed

application, pleaseorder nozzle needle set.

The gun should be heldso that itis perpendicular to the surface of the work piece at all times. Then, the

gun should movein a straight and horizontal line. Arcingthe gun causes uneven painting.

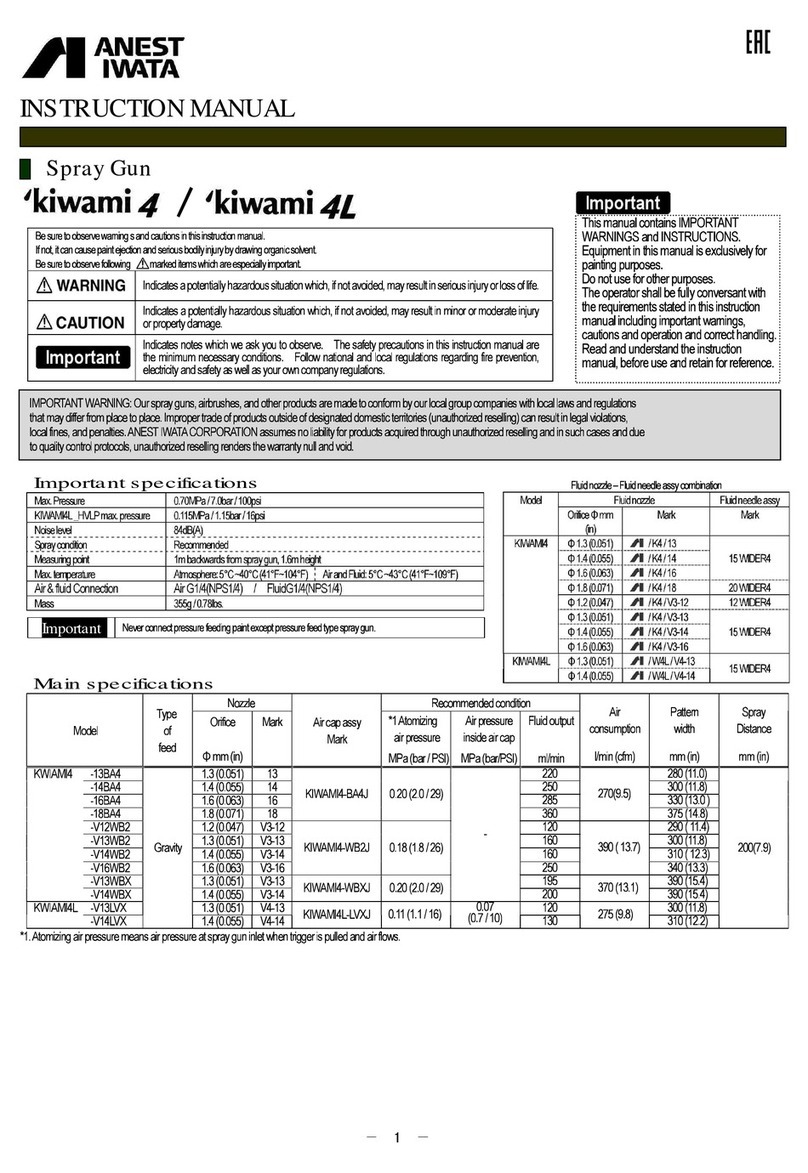

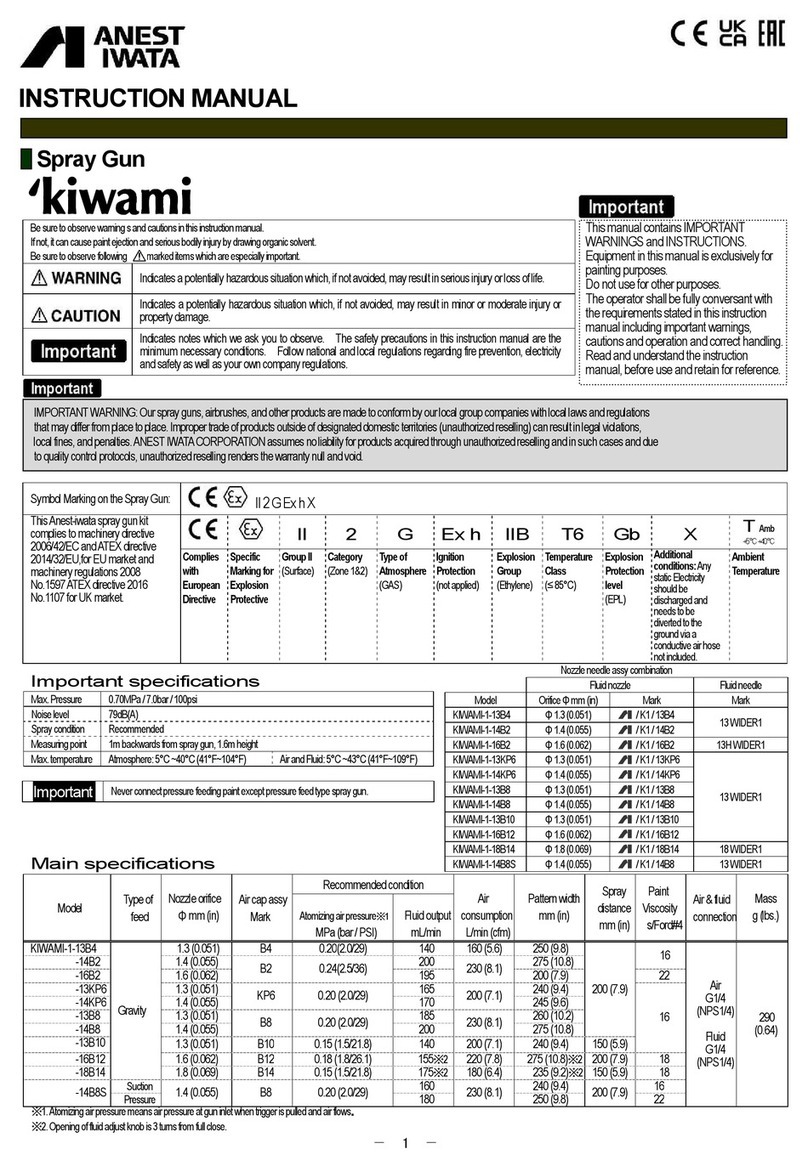

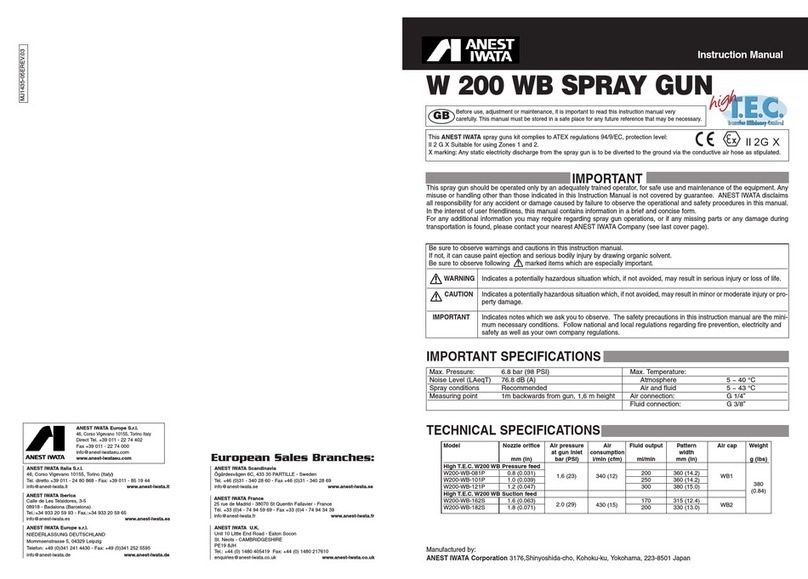

Fluid nozzle Fluid needle set

OrificeΦmm(in) Mark Mark

φ0.4(0.016) 04 Ⅰ

φ0.6(0.024) 06

φ0.8(0.032) 08 Ⅱ

φ1.0(0.039) 10

φ1.2(0.047) 12 Ⅲ

Fluid nozzle-fluid needle set combination

Pulling the triggerof the gun with thepattern adj.Set and fully opened adjust theair regulator in thespray

booth to obtain 0.5~1.0 bar( 7~14 PSI) at thegun inlet as issued on specificationstable ahead.

Inthis waythe gun willatomizewithin 0.7 bar(10 PSI)insideair cap.

NOTE

Usingairhose 12m(39.4ft)long,the innerdiametermustbe a minimum8mm (0.315in) sothe gun can

have the correct air volume to atomize at 0.7 bar (10 PSI) inside air cap.