52 06/2011 Rev. 7.4

Model 2009

06/2011 Rev. 7.4 53

Model 2009

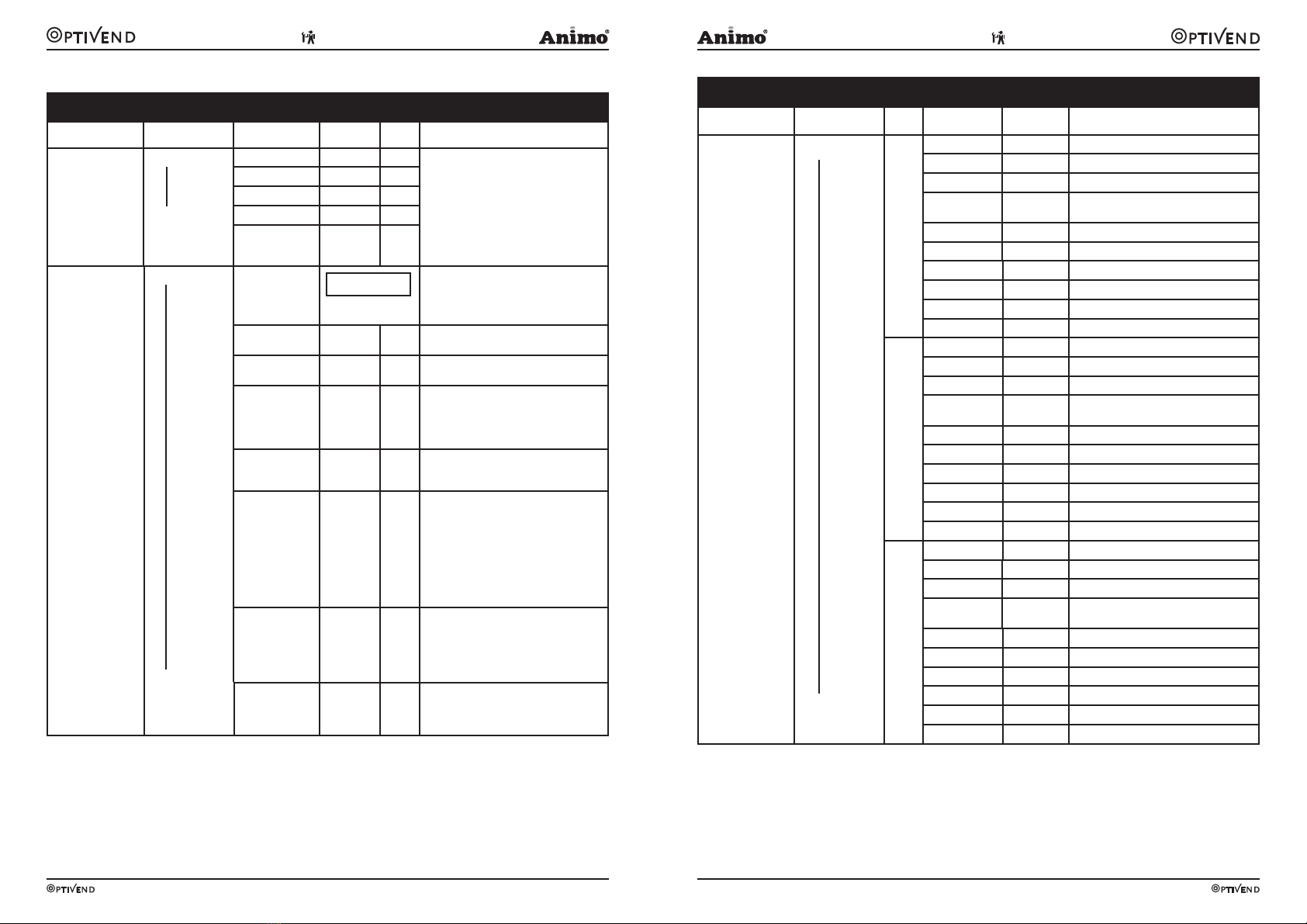

2.3 The service menu

Service menu

Main item Sub item Item Range Set Description

2.1 Quick recipe

* From software

V4.0

Recipe name 1

Recipe name 10

Cup volume

50-250 ml 120ml * 2.1 Quick recipe change into Quick

recipe Pro. Set here directly your

ingredient dispensing time (sec.)

Use this for setting the volume and

strength of coffee, milk, sugar and cocoa

easily per recipe (drink key).

Only the ingredients applicable to the

recipe are shown.

Ingredient 1

0,0 - 50,0 s

Ingredient 2

0,0 - 50,0 s

Ingredient 3

0,0 - 50,0 s

Ingredient 4

0,0 - 50,0 s

2.2 Button setting Button 1

Button 10

<Recipe> +

,

Recipe list see

section 3.3

Change any recipe buttons here that

standard factory settings. All settings

that correspond to selected recipes are

automatically loaded.

Recipe active Yes/no Yes Use this to place the product concerned

out of service.

Price 0,05-

100,00

0,10 For paid dispensing a price can be set

here for each product button.

Cup volume 50-250ml * 120ml Set the desired cup volume here. All other

parameters (e.g. coffee dosage) can be

adjusted automatically. This parameter is

linked to the cup volume item in the menu

2.1 Quick recipe!

Multicup 0-20 0 Set the number of cups that should be

dispensed when the key switch is in the

jug setting.

Key switch 0-1-2-3 0 / 1 Recipe button concerned works as follows:

0= key switch setting n/a

CUP (paid) or JUG* (paid)

1= key switch |: CUP (paid)

key switch –: JUG* (paid)

2= key switch |: no dispensing

key switch –: JUG* (paid)

3= key switch |: CUP (paid)

key switch –: JUG* (free)

(*when multicup is set to >1)

Push & Hold Yes-No No If set to yes: pressing this button starts the

hot/cold water dispensing and releasing it

stops the hot water dispensing.

Use this option only for DV4 , DV5 and

DV 6 in combination with a hot/cold water

recipe button.

Drip time 0-10 sec. 2 sec. The length of time that the product

continues to run from the brewer or mixer.

After this time has elapsed a new drink

selection can be made.

Service menu continued ….

Main item Sub item Sub Item Range Description

2.3 Recipe setting <Recipe name> 1

<Recipe name> 10

Unit 1 DV 1 WT 0,0-90,0 s Waiting time Water 1

DV 1 0-100 ml Dispensing amount Water 1

Rinse 1 WT 0,0-20,0 s Waiting time Rinsing Water 1

Rinse 1 0-15 ml Dispensing amount Rinsing Water 1 Auto-

matically deducted from Water 1

Ingredient 1 WT 0,0-90,0 s Waiting time Ingredient 1

Ingredient 1 0,0-50,0 s Product dispensing time Ingredient 1

Ingredient 2 WT 0,0-30,0 s Waiting time Ingredient 2

Ingredient 2 0,0-50,0 s Product dispensing time Ingredient 2

Mixer1 WT 0,0-90,0 s Waiting time Mixer 2

Mixer 1 0,0-50,0 s Mixing time Mixer 2

Unit 2 DV 2 WT 0,0-30,0 s Waiting time Water 2

DV 2 0-100 ml Dispensing amount Water 2

Rinse 2 WT 0,0-20,0 s Waiting time Rinsing Water 2

Rinse 2 0-15 ml Dispensing amount Rinsing Water 2 Auto-

matically deducted from Water 2

Ingredient 3 WT 0,0-30,0 s Waiting time Ingredient 3

Ingredient 3 0,0-50,0 s Product dispensing time Ingredient 3

Ingredient 4 WT 0,0-30,0 s Waiting time Ingredient 4

Ingredient 4 0,0-50,0 s Product dispensing time Ingredient 4

Mixer 2 WT 0,0-30,0 s Waiting time Mixer 2

Mixer 2 0,0-50,0 s Mixing time Mixer 2

Unit 3

*

DV 3 WT 0,0-30,0 s Waiting time Water 3

DV 3 0-100 ml Dispensing amount Water 3

Rinse 3 WT 0,0-20,0 s Waiting time Rinsing Water 3

Rinse 3 0-15 ml Dispensing time Rinsing Water 3

Automatically deducted from Water 3

Ingredient 5 WT 0,0-30,0 s Waiting time Ingredient 5

Ingredient 5 0,0-50,0 s Product dispensing time Ingredient 5

Ingredient 6 WT 0,0-30,0 s Waiting time Ingredient 6

Ingredient 6 0,0-50,0 s Product dispensing time Ingredient 6

Mixer 3 WT 0,0-30,0 s Waiting time Mixer 3

Mixer 3 0,0-50,0 s Mixing time Mixer 3

* Unit 3 is not used