CONTENTS

6 / 35 NTA47209-100A7

Contents

A. General ........................................................................................................................................................................7

A.1 Introduction............................................................................................................................................................7

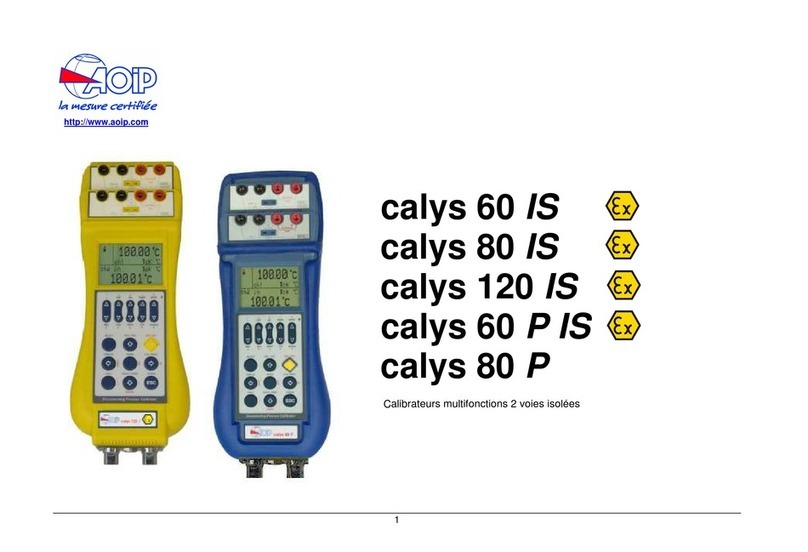

A.2 The instrument.......................................................................................................................................................7

A.3 Safety.....................................................................................................................................................................8

A.3.1 Conformity with safety standards.....................................................................................................................8

A.3.2 Climatic conditions...........................................................................................................................................8

A.3.3 Disposal of instrument at end of life.................................................................................................................8

A.3.4 Instructions......................................................................................................................................................8

A.3.5 Taking measurements.....................................................................................................................................8

A.3.6 Faults and abnormal stresses..........................................................................................................................9

A.3.7 Definitions........................................................................................................................................................9

A.4 Maintenance ........................................................................................................................................................10

B. Using the instrument ..................................................................................................................................................11

B.1 Power-up .............................................................................................................................................................11

B.1.1 Battery replacement ......................................................................................................................................11

B.1.2 Back-up battery (date and time) ....................................................................................................................11

B.1.3 The keypad....................................................................................................................................................11

B.1.4 The measurement and simulation terminals..................................................................................................12

B.1.5 The USB connector.......................................................................................................................................13

B.1.6 Screen...........................................................................................................................................................13

B.1.7 Starting (after powering on)...........................................................................................................................14

B.1.8 Operating modes...........................................................................................................................................14

C. Programming modes..................................................................................................................................................16

C.1 Voltage (DC) measurement .................................................................................................................................16

C.2 Current (DC) measurement .................................................................................................................................17

C.3 Current measurement / auxiliary functions...........................................................................................................19

C.4 Voltage or current (DC) transmission...................................................................................................................20

C.5 Configuration of the ramp generation...................................................................................................................23

C.6 Continuity.............................................................................................................................................................26

D. Parameter settings.....................................................................................................................................................27

D.1 Contrast adjustment.............................................................................................................................................27

D.2 Date and time setting...........................................................................................................................................27

D.3 Preferences” setting.............................................................................................................................................27

D.3.1 Filtering setting..............................................................................................................................................27

D.3.2 Display resolution setting...............................................................................................................................28

D.3.3 Lighting duration setting ................................................................................................................................28

D.3.4 “Key beeping” setting.....................................................................................................................................28

D.3.5 Language setting...........................................................................................................................................28

D.4 "Maintenance" menu............................................................................................................................................29

D.5 "About the instrument" menu ...............................................................................................................................29

E. Software updatE.........................................................................................................................................................30

F. Calibration and Adjustment........................................................................................................................................31

G. Technical specifications .............................................................................................................................................32

G.1 Measurement function .........................................................................................................................................32

G.1.1 DC voltage.....................................................................................................................................................32

G.1.2 Direct current.................................................................................................................................................32

G.2 "Transmission" function .......................................................................................................................................33

G.2.1 DC voltage.....................................................................................................................................................33

G.2.2 Direct current.................................................................................................................................................33

G.3 "Continuity" function.............................................................................................................................................33

G.4 Power supply - Autonomy....................................................................................................................................33