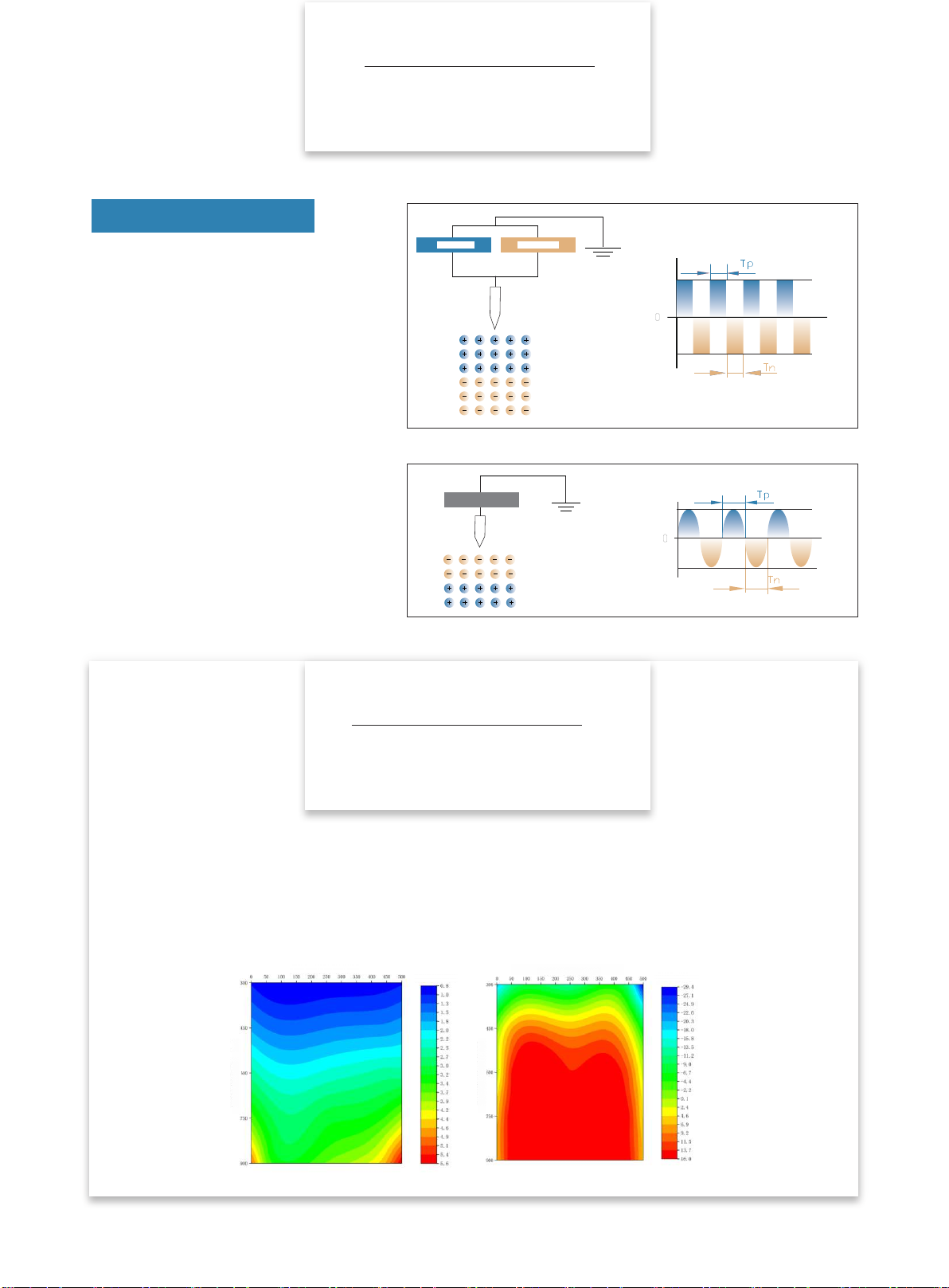

Ion balance/

ion output frequency adjustable

Intelligent Control

Positive high voltage amplitude

正高压幅值

Negative high voltage amplitude

time

The negative ion output increases with the

increase of negative high voltage amplitude

The negative ion output increases with the

decrease of negative high voltage amplitude

Adjust ion balance voltage

Vp

Vp Vp

Vp

Vn

Vn Vn

Vn

Adjust the output frequency of

positive and negative high voltage

The output frequency of positive and

negative ions increases

The output frequency of positive

and negative ions decreases

time

-HV

(Negative high voltage)

The output ratio of positive and negative ions is adjustable, which can be used to

adjust the ion balance voltage

The output frequency of positive and negative ions is adjustable, which can be

applied to different discharge distance to achieve faster discharge speed

+HV

voltage)(Positive high

Positive voltage working time

Negative voltage working time

-HV

(Negative high voltage)

+HV

(Positive high voltage)

Positive voltage working time

Negative voltage working time

time

-HV

(Negative high voltage)

+HV

(Positive high voltage)

-HV

(Negative high voltage)

+HV

(Positive high voltage)

Positive voltage working time

Negative voltage working time

Positive voltage working time

Negative voltage working time

-HV

(Negative high voltage)

+HV

(Positive high voltage)

-HV

(Negative high voltage)

+HV

(Positive high voltage)

+HV

(Positive high voltage)

+HV

(Positive high voltage)

-HV

(Negative high voltage)

-HV

(Negative high voltage)

Positive high voltage amplitude

Positive high voltage amplitude

Negative high voltage amplitude

Negative high voltage amplitude

Negative high voltage amplitude

Adjust ion balance voltage

time

time time

Adjust the output frequency of

positive and negative high voltage

time time