9code HC0300.00GB ed.A-2212

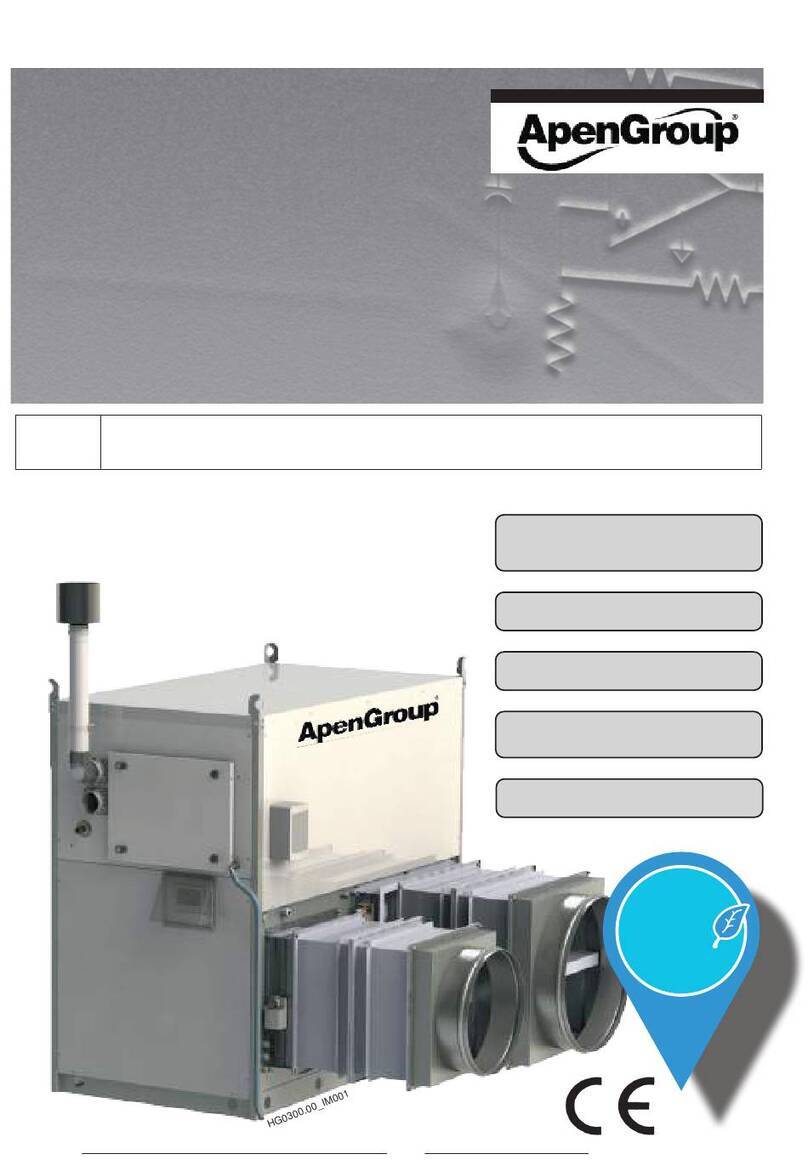

HYN

AQUAPUMP HYBRID HYBRID SYSTEM

In order to ensure the correct operation of the

equipment, preventing its damage or problems for persons,

it is mandatory to add a percentage of glycol to the lling

water, proportional to the minimum winter temperature of the

area where the boiler is installed or the C11101 mechanical

antifreeze valve kit.

It is strictly FORBIDDEN to connect a system lling

circuit to the waterworks mains.

We recommend to check the water and glycol content

inside the circuit by means of a refractometer on a yearly

basis.

Using galvanised iron/steel pipes may bring about

corrosive phenomena when using antifreeze. Therefore

we DO NOT suggest using this material.

Warnings for glycol use:

In case of direct intake of high doses, the product may cause

eects on the central nervous system, respiratory diseases and

kidney damage. Avoid contact with skin and eyes – protect the

respiratory tract.

Do not allow the product to enter sewers, surface water and

groundwater, ground.

Use gloves, rubber boots and normal tight working clothing.

Wear tight goggles.

For further information, refer to the safety data sheet of:

Cookson Electronics, Alpha Metals S.p.A.,

Via Ghisalba 1, 20021 Bollate, Milano, Italy

Ph: +39.02.383311 Fax: +39.02.38300398

www.fernox.com

For its machines, APEN GROUP tested and recommends to

use ALPHI 11 glycol by Fernox or X500 glycol by Sentinel; the

following KITS contain ALPHI 11 packs by Fernox with dierent

capacity:

C07200-05 5 litres

C07200-25 25 litres

2.9. Unpacking

The unpacking operation must be carried out by using suitable

tools or safety devices where required. Recovered packaging

materials must be separated and disposed of according to

applicable regulations in the country of use.

While unpacking the unit, check that the unit and all its parts

have not been damaged during transport and match the order.

If damages have occurred or parts are found to be missing,

immediately contact the supplier.

The manufacturer is not liable for any damages occurred

during transport, handling and unloading.

Packing material disposal

The packing safeguards the product from transport damages.

All the materials used are environmentally friendly and

recyclable. Please contact a specialised distributor or your local

administration for more information on waste disposal.

2.10. Dismantling and disposal

Should the machine be dismantled or demolished, the person

in charge with the operation shall proceed as follows.

Disposal of end-of-life products

This equipment is marked in compliance with

European Directive 2012/19/EU on waste

electrical and electronic equipment (WEEE).

This Directive denes the rules for collecting and

recycling waste equipments throughout the entire

territory of the European Union.

WEEE contains both pollutants (that can negatively aect the

environment) and raw materials (that can be reused). IT is

therefore necessary to subject WEEE to appropriate treatments,

in order to remove and safely dispose of pollutants and to

extract and recycle raw materials. IT is forbidden to dispose of

WEEE as unsorted waste. These operations facilitate recovery

and recycling of the materials, thus reducing the environmental

impact.

All materials recovered will be processed and disposed of

according to what provided for by the laws in force in the country

of use and/or according to the standards indicated in the safety

sheets of the chemicals.

INFORMATION FOR DISPOSAL valid in ITALY (Legislative

Decree 49/2014)

The HYN series hybrid machines at the end of their life are

considered “waste electrical and electronic equipment”, classied

as “professional WEEE”. According to Decree 49/2014 the

“professional WEEE” classication sets forth the obligation to

dispose of the products in treatment facilities suitable for this

kind of waste.

Apen Group is part of a collective system (Union Ecoped/

Ridomus) for the sorted waste management of professional

WEEE according to art. 13 of Legislative Decree 49/2014.

Please contact the Apen Group for end-of-life products so as

to obtain all the information necessary for their correct waste

disposal, which is possible thanks to the Collective System

(Union) to which the company is associated.

Please remember that product disposal without complying with

the mode described above is a violation liable to administrative

and penal sanctions.

INFORMATION FOR DISPOSAL valid abroad (EU COUNTRIES

except Italy).

The European Directive 2012/19/EC shall be implemented in

every EU member state. There may be dierent application

modalities for the various member states, even in terms of

modality for waste disposal depending on its type (House-hold

or Professional WEEE). To this regard at the end of the life of

the product, we highly recommend you call the distributor or

installer so as to obtain information on the correct disposal, in

compliance with the existing laws of the installation country.