4

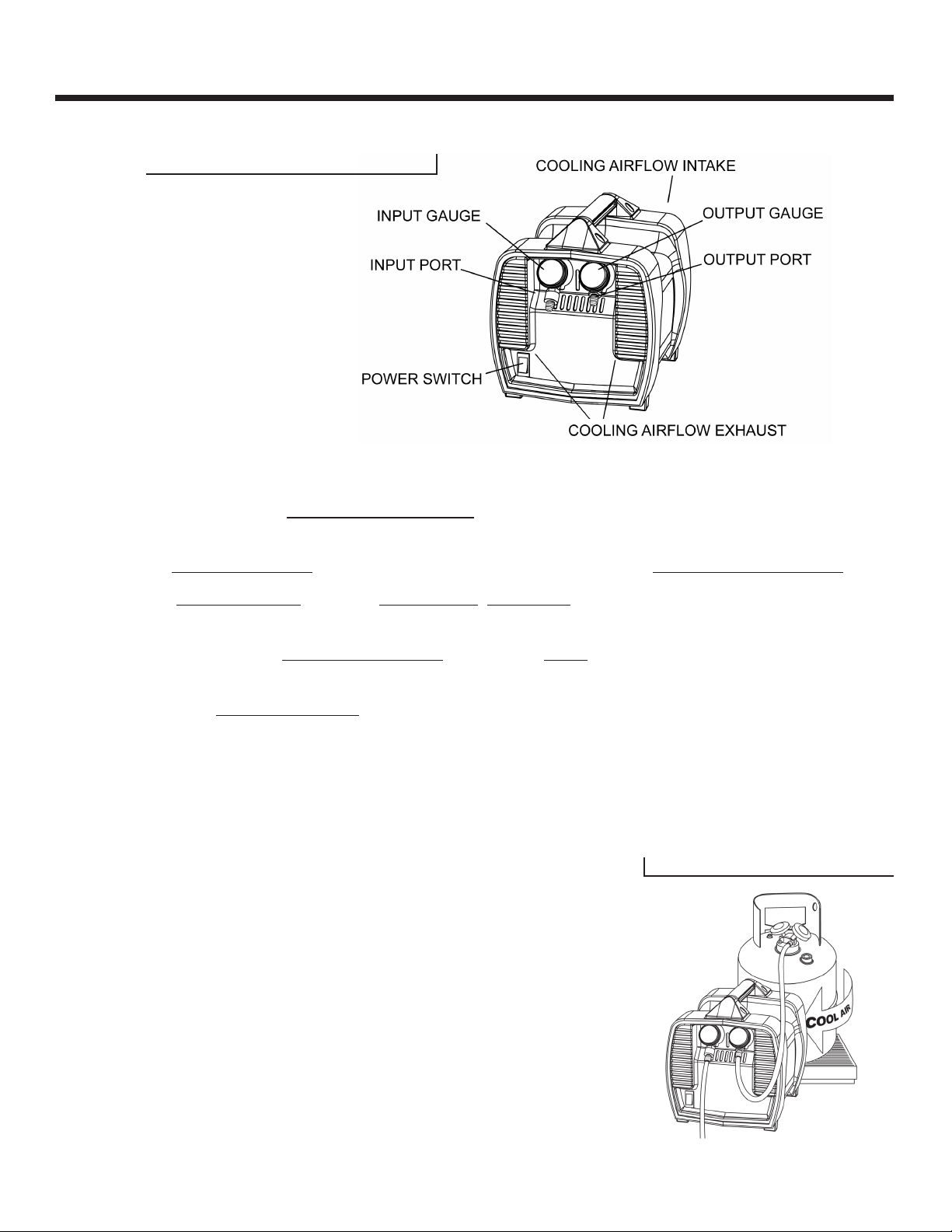

G1SINGLE OPERATION MANUAL

© 2023 APPION INC. - ALL RIGHTS RESERVED

HAZARD: RISK OF EXPLOSION OR FIRE

⚠DANGER

Use of this equipment may pose certain explosion and fire hazards.

WHAT CAN HAPPEN HOW TO PREVENT IT

Flammable/combustible gases and air may become

unknowingly ingested through leaks in hoses,

gaskets, connections or leaking seals, leading to

compression of these gases. Air and hydrocarbons,

if pumped to a tank, create an explosive mixture

that random static electricity could ignite.

Do not use in the vicinity of spilled or open

containers of gasoline, propane, butane, acetylene,

or other flammable gases.

Do not use near open sewer lines which may be

emitting sewer gases.

Flammable substances may ignite or explode when

compressed in certain situations.

Do not use this machine to pump hydrocarbons,

including blends containing butane, isobutane, or

propane. Hydrocarbons are flammable substances

and may ignite or explode when compressed in

certain situations.

Improper use of extensions cords may result in

overheating or fire in the cord or machine.

Use only 12AWG or 10AWG extension cords:

- Up to 25 Feet: 12/3 UL/CSA cord

- Up to 100 Feet: 10/3 UL/CSA cord

Warnings and Safety Information(continued)

A3 REFRIGERANT DANGER

Do not use this machine to pump hydrocarbons, including A3 refrigerants.

While most refrigerant recovery machines on the market are able to pump hydrocarbon refrigerants such as

propane and butane, none of them can do so safely without creating an explosion hazard in the tank.

A significant risk inherent with the recovery of hydrocarbon refrigerants is the potential to accidentally

ingest air and pump this air into a tank with hydrocarbons. This compressed hydrocarbon and air mixture

within the tank can create an explosion hazard. The accidental ingestion of air can come from many

scenarios. These scenarios include but are not limited to faulty system components, improper system

installation, improperly purged recovery hoses, worn hose gaskets, and worn recovery machine compressor

components.

Industries that work with hydrocarbons avoid these risks by constantly venting air and hydrocarbon vapors

while transferring in a pure liquid-only state. The transfer process only stops once the liquid hydrocarbon

begins to spray out of the vent port of the receiving tank. This transfer process is the only way to make sure

no air or other non-condensables are in the receiving tank.

The procedure explained above is not possible to perform when pumping hydrocarbon vapor from a system

with a recovery machine. Since there is no safe way to totally eliminate air being ingested during the recovery

process, pumping hydrocarbons with any recovery machine should not be done under any circumstance.

⚠DANGER