Heating Element Indicator Light Robert Shaw

Thermostat

H1 L1

H2 L2

Heating Element Indicator Light

Ranco

Thermostat L1

H1 H2

L2

9

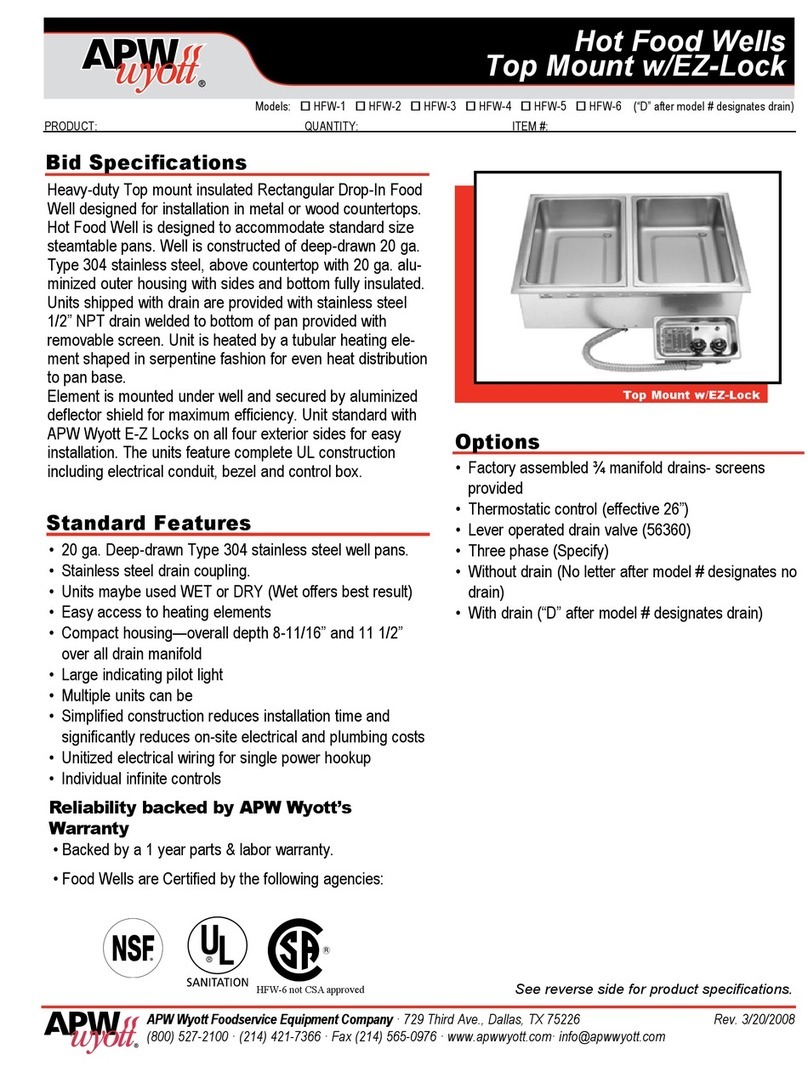

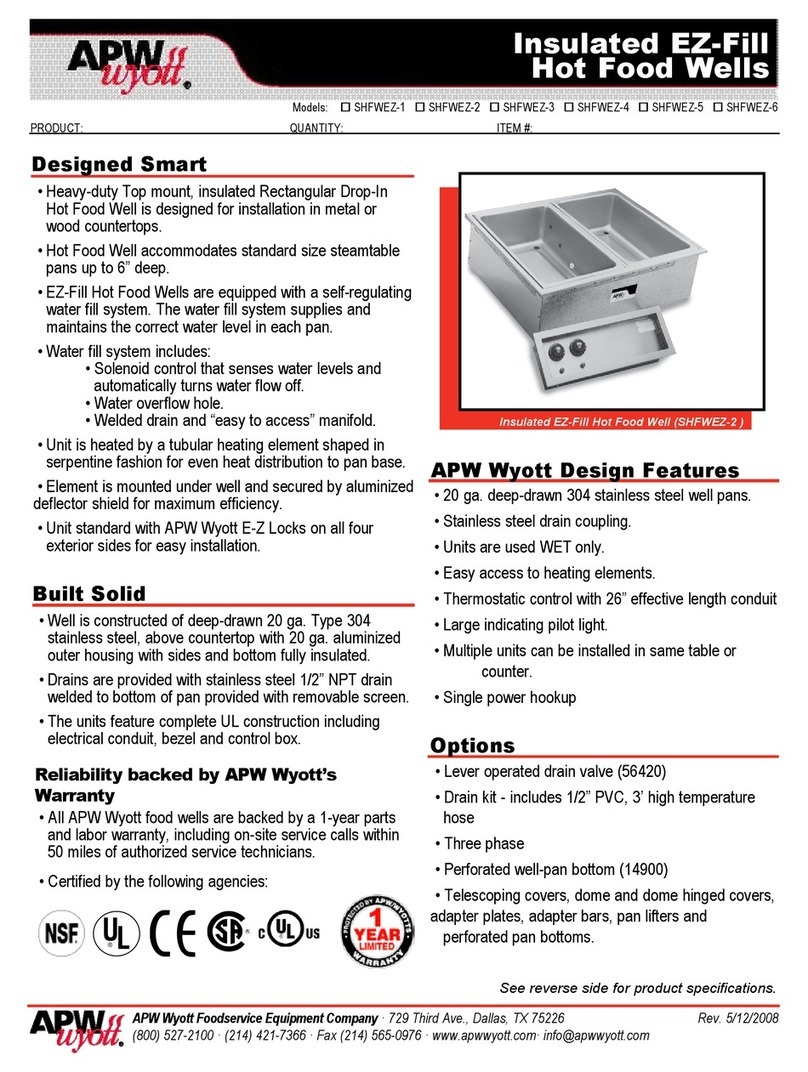

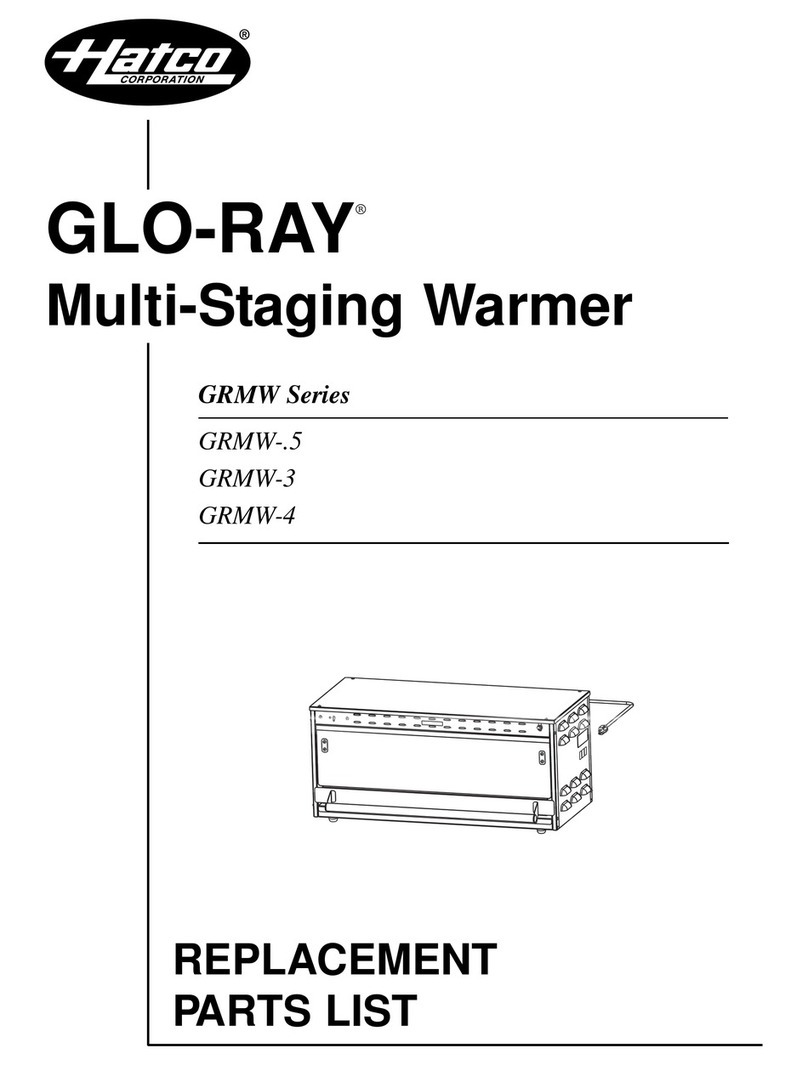

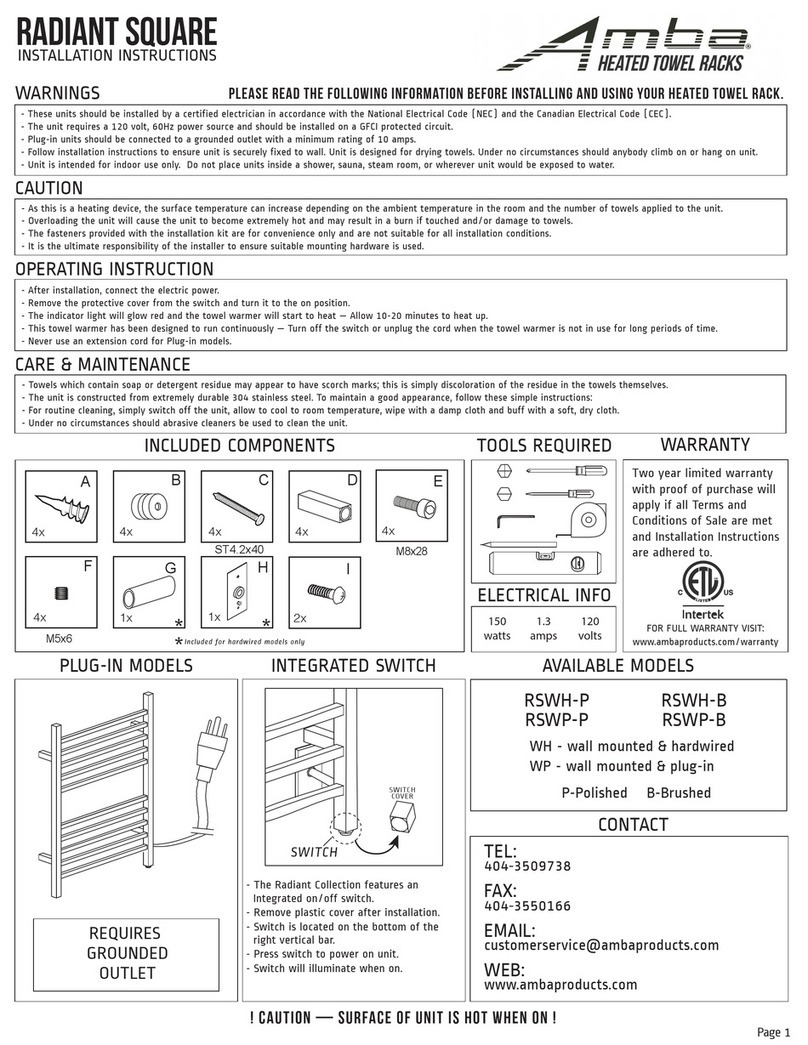

1 54561 Control Box W/Assy 12.50 "

2 54503 Bezel Control 12.50"

3 56527 Thermostat 36" Capillary

4 56528 Knob, Black

5 63012 Indicator Light (56530)

6 54577 Adapter, 1/4" Tube To 3/8” Pipe

7 54578 Tubing, Copper, 1/4”

8 55343 90° Conduit Connector

9 54511 Octal Base Use With 54510

10 54524 Bracket, Solenoid Valve

11 54513 Water Solenoid Valve

12 54510 Liquid Level Control Octal Base

XXXX Liquid Level Control Open Board

13 54512 Hold Down Strap Use With 54510

14 30201 Terminal Block

15 54508 Brass Fitting 1/8 NPT x 1/4 Compression

16 54572 7 Qt. Round Well Pan W/Copper Tube

17 50817 Plate, Heat Diffuser

18 55964 Heating Element 208/240V, 500W/660W

19 55696 Bracket, Element Holder

20 55695 Bracket, Element Holder

21 89025 10-24 Speed Nut

22 55992 Bottom Cover

23 89059 #10 External Lock Washer

24 89061 Nut, Hex 10-24

25 54544 O-Ring For Probe Holder

26 54543 Probe Holder

1 54561 Control Box W/Assy 12.50 "

2 54503 Bezel Control 12.50"

3 56527 Thermostat 36" Capillary

4 56528 Knob, Black

5 63012 Indicator Light (56530)

6 54577 Adapter, 1/4" Tube To 3/8” Pipe

7 54578 Tubing, Copper, 1/4”

8 55343 90° Conduit Connector

9 54511 Octal Base Use With 54510

10 54524 Bracket, Solenoid Valve

11 54513 Water Solenoid Valve

12 54510 Liquid Level Control Octal Base

XXXX Liquid Level Control Open Board

13 54512 Hold Down Strap Use With 54510

14 30201 Terminal Block

15 54508 Brass Fitting 1/8 NPT x 1/4 Compression

16 54572 7 Qt. Round Well Pan W/Copper Tube

17 50817 Plate, Heat Diffuser

18 55964 Heating Element 208/240V, 500W/660W

19 55696 Bracket, Element Holder

20 55695 Bracket, Element Holder

21 89025 10-24 Speed Nut

22 55992 Bottom Cover

23 89059 #10 External Lock Washer

24 89061 Nut, Hex 10-24

25 54544 O-Ring For Probe Holder

26 54543 Probe Holder

27 54546 Washer 1/2-20 SS

28 54549 Nut, Hex 1/2-20

29 54545 O-ring For Screw

30 88971 Screw 8-32 X 1-1/2 SS

31 54548 Spacer, Probe Holder

32 89063 Nut, Hex 8-32

33 56542 Plate, Dial-Wells

34 88961 10-24 Hex Nut, Green-Ground

35 89054 6-32 KEPS Nut

36 88993 10-32 X 3/8 Truss Head Screw

37 89073 #8 X 1/2 Sheet Metal Screw

38 51016 Cover, Terminal

39 55342 3/8" Conduit

40 55340 Anti-Short Bushing

41 89120 Jiffy Clip

42 88889 8 X 1/2 AB SMS, Phl Truss

43 88977 6-32 X 1.0 Slotted Pan Head

44 55333 Wood Mount Kit SM-50-7

45 55402 EZ Lock Clip 4 Tab

56655 Drain Strainer

54532 Wire Set Two Well

54533 Wire Set Three Well

54534 Wire Set Four Well

54535 Wire Set Five Well

54536 Wire Set Six Well

27 54546 Washer 1/2-20 SS

28 54549 Nut, Hex 1/2-20

29 54545 O-ring For Screw

30 88971 Screw 8-32 X 1-1/2 SS

31 54548 Spacer, Probe Holder

32 89063 Nut, Hex 8-32

33 56542 Plate, Dial-Wells

34 88961 10-24 Hex Nut, Green-Ground

35 89054 6-32 KEPS Nut

36 88993 10-32 X 3/8 Truss Head Screw

37 89073 #8 X 1/2 Sheet Metal Screw

38 51016 Cover, Terminal

39 55342 3/8" Conduit

40 55340 Anti-Short Bushing

41 89120 Jiffy Clip

42 88889 8 X 1/2 AB SMS, Phl Truss

43 88977 6-32 X 1.0 Slotted Pan Head

44 55333 Wood Mount Kit SM-50-7

45 55402 EZ Lock Clip 4 Tab

56655 Drain Strainer

54532 Wire Set Two Well

54533 Wire Set Three Well

54534 Wire Set Four Well

54535 Wire Set Five Well

54536 Wire Set Six Well

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTIONITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

HARDWARE NOT SHOWNHARDWARE NOT SHOWN

SM-50 WIRING DIAGRAMS

PARTS LIST SM50EZ EZ FILL MULTI WELLSPARTS LIST SM50EZ EZ FILL MULTI WELLS