aquilar AquiTron AT-MZA User manual

AT-MZA

Multi Zone Alarm

AquiTron

INSTALLATION

INSTRUCTIONS

MZA

115Vac +15%, -20%; 50/60 Hz

230Vac ±10%; 50/60 Hz

12Vdc ±20%

POWER CONSUMPTION

12 watt maximum

RELAYS

Number: One LEAK relay per zone (max 8),

One common LEAK and one summary FAULT.

Type: SPDT

Rating: 3 A at 250Vac/24 Vdc

TEMPERATURE

Storage: -18°C to 60°C (0°F to 140°F)

Operating: 0°C to 50°C (32°F to 122°F)

ENCLOSURE

NEMA 12; IP54

INSTALLATION ITEMS

(NOT SUPPLIED)

• Wall fasteners for surface mounting (four

screws)

• Rubber or elastomeric washers to seal

at mounting points

• Semi-ush recess ange (optional)

TOOLS REQUIRED

• Drill or hole punch for electrical

conduit entries

• Phillips (cross-head) screwdriver

• Small at-head screwdriver

STORAGE

Keep the module in a dry place prior to

installation to avoid possible damage to

internal components.

ADDITIONAL ITEMS

AT-BU

Battery Unit c/w battery

for 72 hrs operation

AT-BAT

Replacement 12Vdc, 7Ah Battery

AT-MZA-SFMF

Semi Flush Mounting Flange

APPROVALS

The MZA is approved for use in ordinary

areas. The module must be located in an

Ordinary Area, but may monitor intrinsically

safe TraceTek sensing cables located in

Hazardous Locations:

• TraceTek sensing cable in Class I, Division 2,

Groups A, B, C, D =Hazardous Locations.

• If protected by agency-approved zener

barrier TraceTek sensing cable in Class I,

Division 1, Groups A, B, C, D Hazardous

Locations (Zone 0 or Zone 1 in Europe).

Contact your TraceTek distributor/agent

to select proper zener barrier.

MAXIMUM CIRCUIT LENGTH

100m (328ft) TraceTek sensing cable or 10

water or optical oil probes per zone. Leader

and jumper cable lengths are not included

in this limitation.

Please read these

instructions carefully

and keep them in a

safe place (preferably

close to the module)

for future reference.

These instructions

must be followed

carefully to ensure

proper operation.

AT-MZA

Multi Zone Alarm

A. GENERAL INFORMATION

The MZA multi zone alarm has been designed specically for use with TraceTek sensing cables

(TT1000, TT1100, TT3000, TT5000, TT5001 and TT7000). The MZA can monitor per zone up to

100 m (328 ft) of sensing cable, or 10 water detection probes. Optical probes, oat switches

and level indicators can also be incorporated into the system.The MZA is designed for use in

ordinary areas with temperatures of 0°C to 50°C (32°F to 122°F).

B. PRODUCT INFORMATION

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

1

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

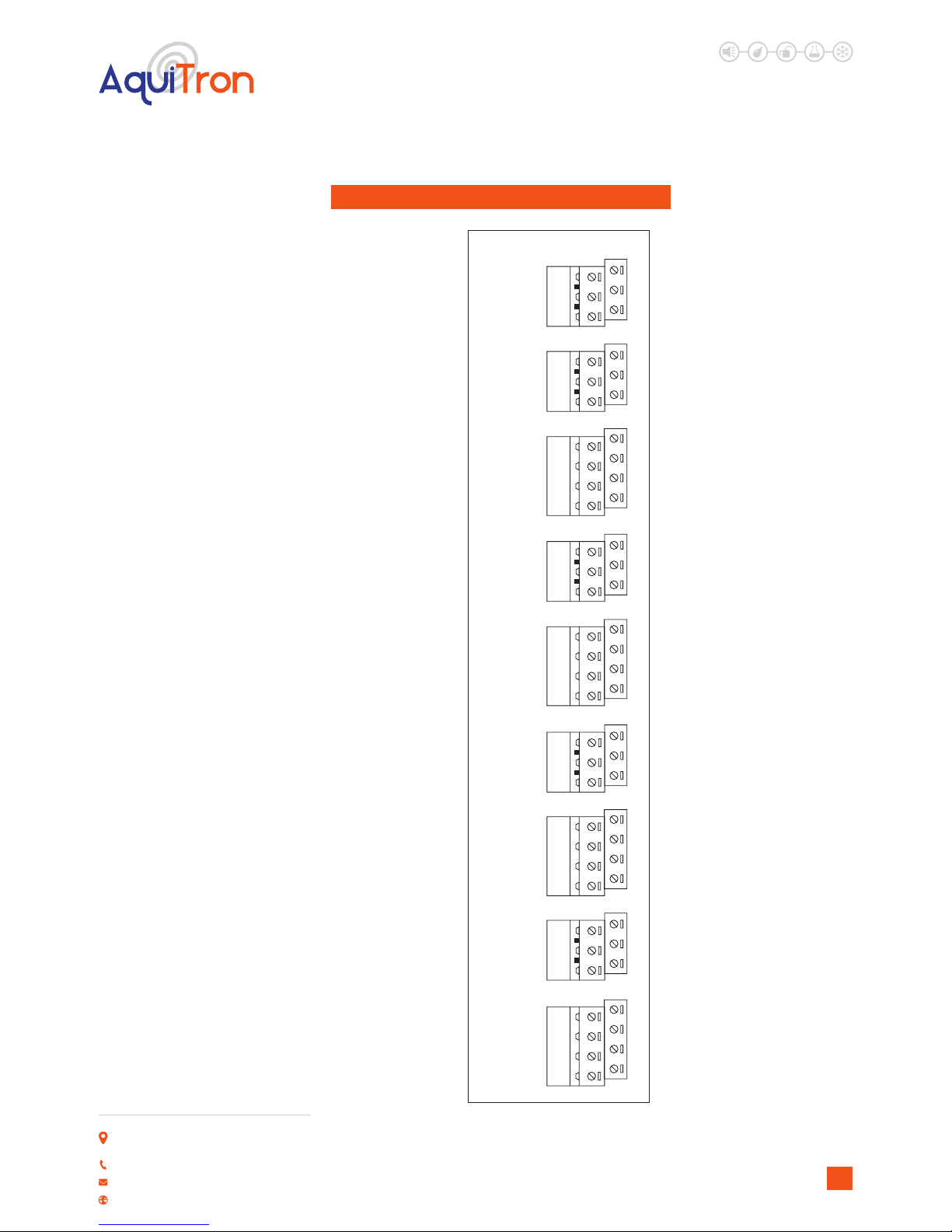

1. LEDs with icons

2. Mute Button

3. Reset Button

4. Zone LEDs

5. Battery Connection

6. Spare Fuse

7. Fuse (1600mA, 250 V)

8. Fuse (1600mA, 250 V)

9. Zone exp card connection

10. (Not Used)

11. Power cable terminal block

12. Motherboard

13. Summary leak & fault relay plug & socket

14. Z1/2 Leak relay cable plug and socket

15. Z1/2 Sensing cable plug and socket

16. Z3/4 Leak relay cable plug and socket

17. Z3/4 Se nsing cable plug and socket

18. Z5/6 Leak relay cable plug and socket

19. Z5/6 Sensing cable plug and socket

20. Z7/8 Leak relay cable plug and socket

21. Z7/8 Sensing cable plug and socket

22. Ground/earth stud

23. Ribbon cable

24. Ground/earth stud

25. Buzzer mute link

26. User Interface board

1

2

3

4

5

26

PL PL PL PL

67 89 11 12

25 24 2223 21 20 19 18 17 16 15 14 13

Note: To avoid damage to the MZA and the MZA-EXP electronics, store them in their

cardboard boxes until construction is complete.

2

67 89

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

3

Choose a location indoors where the module will be protected from the elements and

temperature extremes

WARNING: Ignition hazard. Do not mount the MZA unit in a hazardous location. Sensing cable

connected to the MZA may (subject to approvals restrictions) be located in hazardous locations, but

the module itself must

C. SELECT A MOUNTING POSITION

PL PL PL PLPL PL PL PL

Remove all six screws attaching motherboard

Figure 1

PREPARE THE MODULE FOR

MOUNTING

Important: The MZA is an electronic unit.

During installation, take the following

precautions to avoid damage to its electronic

components:

• Handle with care, avoid mechanical

damage.

• Keep the electronics dry.

• If handling circuit boards, hold them by

their edges to avoid physical contact with

electronic components.

• Avoid exposure to static electricity.

• Avoid contamination with metal lings,

liquids, or other foreign matter.

• Remove the module from its packaging.

• Open the enclosure door using a at-blade

screwdriver or coin.

• Anti static precautions should be taken

before touching the boards inside.

• Carefully disconnect the ribbon cable from

the motherboard.

• Unscrew the four Phillips (cross-head)

screws holding the motherboard to

the enclosure (see Fig 1). Remove the

motherboard, and put it out of harm’s way.

• Taking care to protect the User Interface

board on the enclosure door, drill/punch

entries as required (see Fig 2).

PL PL PL PL

Figure 2

Additional area

avalable for

cable entries

(no knockouts)

MOUNT THE MODULE

The module mounts with four screws with

mounting centers as noted in Fig 3. To seal

around the mounting screw (necessary to

maintain the IP54 rating), use a rubber or

elastomeric washer.

• Note: The AquiTronTM/ TraceTek sensing

circuit is power limited, so the TraceTek

leader or jumper cable and the power

supply cable must not run in the same

conduit.

• Fit conduit bushings/adapters.

• Remove all traces of metal lings and dust

from inside the module enclosure.

Figure 2

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

REASSEMBLE THE MODULE

Note: Before replacing the motherboard,

ensure that the interior of

the enclosure is clean.

• Replace the motherboard and secure it in

place with the Phillips (cross-head) screws.

• Reconnect the ribbon cable (taking care not

to bend any pins in the connection).

• Close and secure the door of the enclosure.

4

190m m

240m m

210m m

165m m

Figure 3

Cable entry knockouts are provided as

follows:

Back plate 4 x 20mm and 3 x 3/4”

Base of endourse 6 x 20mm and 5 x 3/4”

D. PREPARE SENSING CABLE / SENSING PROBE / DEVICE

Ensure that the sensing cable (sensing device) has been installed in accordance with the

instructions provided.

MAKE CONNECTIONS

• Conrm that the power to the MZA unit has

been turned o.

• Open the enclosure door.

• Feed the end of the TraceTek modular

leader cable (or bulk jumper cable) through

the knockout/adapter/bushing if tted.

• Connect the four colour-coded wires to the

Sensor Interface plug, X3, X7, X10 and X12

(see Fig 4).

SENSOR

RED

GR N

YEL

BLK

x3

x7

x10

x12

• Select a spare connector between zones 1

to 8.

• Zones 1-2 do not require the insertion of a

zone expansion card, MZA-EXP.

• Three cards can be added to the base unit,

giving a total of 8 individual zones. Provided

the relevant zone expansion card has been

• the relevant zone expansion card has been

inserted, you can select any sequence for

connecting the sensing cable or sensing

devise.

Important: Observe the colour coding.

If wires are not connected to the correct

terminals, the leak detection system cannot

operate properly.

Insert the sensing cable (SI) plug into the SI

socket (item 15, 17, 19, 21 on the product

illustration on the rst page).

ISOLATE SPARE SENSING ZONES

Each spare sensing zone circuit or the second

zone in any of the two zone blocks, where

an expansion card is tted, that is not to

be used must be terminated with loops of

cable between red-green and yellow-black.

(See gure 5). This will prevent the system

identifying this zone as having a cable break.

However, should there be a requirement for

all three-expansion cards to be installed, but

not used, then these must be terminated in a

similar fashion.

Figure 3

Figure 4

SENSOR

RED

GRN

YEL

BLK

x3

x7

x10

x12

Figure 7

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

5

CONNECTING THE POWER WIRING

• Open door of MZA enclosure.

• Pass the power cable through the knock-

out/adapter/bushing if tted.

• Note: Proper grounding/earthing is

important to avoid the possibility of

electromagnetic interference.

• Connect the power supply wires to the

special three-pin terminal block marked LNE

(Live, Neutral, Earth), observing the polarity.

E. CONNECTING THE POWER CABLE AND RELAYS

x15

Figure 4

LN

• The electrical supply should be fused

at no more than 3 amps via an un-

switched fused spur adjacent to the

unit.

• Note: Do not exceed maximum

voltage.

• The unit is equipped with a 12Vdc battery

back-up power circuit. If this option is

required connect the + and - (positive and

negative) battery leads (leads not supplied)

(g 7).

BATTERY BACKUP

Figure 5

• A separate battery unit is available

AT-BU which will house a 12Vdc 7Ah

battery - AT-BAT.

• Batteries should be tested, maintained

and replaced in accordance with the

battery manufacturers instructions

and recommendations.

COCONNECT THE LEAK AND FAULT

(CABLE BREAK) RELAYS

The MZA has:

One LEAK relay per zone

One common LEAK relay

One summary FAULT relay

RELAY IDENTIFICATION

LEAK relays:

Zones1&2,X13-Z1bottom,Z2top

Zones3&4,X11-Z3bottom,Z4top

Zones5&6,X8-Z5bottom,Z6top

Zone7&8,X5 -Z7bottom,Z8top

Note: See gure 8 (at the back of this

document) for a complete gure layout.

Figure 5

Figure 6

Figure 7

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

COMMON LEAK RELAY

X14 Bottom connection

FAULT RELAY:

Common to all zones X14 Top connection

All relays are SPDT and independent of

the next.The MZA’s FAULT relay will also

indicate power failure as the relay contacts

will de-energize to signal an alarm condition.

Therefore, loss of power as well as a cable

break would trip the relay and any equipment

connected.

x14

x13

x11

x8

x5

N/O N/CC

6

Note: The relay plugs can accept wires 12 to

24 AWG. Cable should have a temperature

rating of 65°C.

Note: Maximum load for relays is 3 amps,

250Vac/24Vdc.

F. CONNECTING THE ZONE EXPANSION CARDS

Important: The MZA-EXP is an electronic unit. During installation, take the following

precautions to avoid damage to its electronic components:

• The MZA panel should not be powered

when installing the MZA-EXP card.

• Anti static precautions should be taken

before touching the boards inside.

• Handle with care, avoid mechanical

damage.

• Keep the electronics dry.

• If handling circuit boards, hold them by

their edges to avoid physical contact with

electronic components.

• Avoid exposure to static electricity.

• Avoid contamination with metal lings,

liquids, or other foreign matter.

• A maximum of three MZA-EXP cards can be

added to a MZA panel.

• Each MZA-EXP provides two additional

zones of sensing.

• Remove the card from it’s static free

packaging.

• Insert the rst card on vertical connector

marked zones 3-4 and the following cards

on zones 5-6 and zones 7-8. The card will

only t in one direction.

• Push the card securely to the base

connector.

• Once the card has been securely installed

the MZA panel can be powered.

INSTALL ZENER BARRIER, IF

APPLICABLE

When sensing cable will be located in Class

1, Division 1 locations, approval agencies

require that the sensing cable be protected

with a zener barrier between the sensing

cable and the MZA module. A zener barrier

may also be used to provide lightning

protection for the module when the

sensing cable may be exposed to electrical

discharges. Contact your distributor/agent to

select the proper zener barrier. One will be

required for each sensing zone.

When installing a zener barrier, wire

it in accordance with the instructions

provided with the kit.

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

VOLT FREE RELAY OPERATION

All leak detection alarm panels supplied by Aquilar are provided with, at least one, volt free

relay.These are also known as volt free contacts or dry contacts. They are used to operate

auxiliary equipment such as – valves, sounders, pumps, beacons etc., sending closed or open

contact signals to Building Management Systems (BMS) or other logic level controls.

As the name suggests, there is no voltage present at the terminals. So, to operate a valve,

for example, you need to have a dedicated power supply which is then fed through the relay

(typically the live feed) to switch it on or o accordingly.Typical wiring is as follows:

Please ensure that the load does not exceed the ratings of the volt free relay. This is stated in

the relevant product’s data sheet / installation instructions.

Wiring of volt free relays should be undertaken by a suitably qualied technician and in

accordance with the regulations and standards in their industry/country. These notes are only

intended as a guide and Aquilar Ltd bears no responsibility for the installation or operation of

the unit.

7

//

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

//

//

//

//

//

//

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

//

/

//

/////

//

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

//

/////

//

//

/

/

/

/

/

Class I, Division 1

(Zone 0 or Zone 1 in Europe)

Hazardous Location

Ordinary Area

Zener

barrier

Leader or jumper cable

Jumper cable

Sensing cable

MZA

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

G. TEST PROCEDURE

1. After connections are complete supply

power to the unit. If the sensing circuit

is complete and free of leaks or other

problems, the green Monitoring LED only

will illuminate.

2. Leak Simulation: For systems using TT1000,

TT3000 sensor cable or a detection probe,

use a TraceTek Mapping Tool or a small

container of water to simulate a leak. After

the time delay has expired (maximum 15

seconds) look for the following indications:

Red LEAK LED on

Green POWER LED on

LEAK RELAY in ALARM condition

(Note: This may cause equipment shut

down if devices are connected to the LEAK

relay contacts)

Remove simulated leak

Red LEAK LED goes out

For TT5000 and TT5001 systems, simulate a

leak condition by tightly bending and holding

the sensor cable.

3. Cable Break Simulation: For any sensor

system, disconnect any one wire at the

sensor cable terminal block or disconnect

any connector in the system. Look for the

following indications:

Yellow CABLE BREAK LED on

FAULT RELAY in ALARM condition

Restoring the connection should cause the

MZA to return to the normal indications for

that zone.

1. Complete a system inspection in the

presence of the owner.

2. Ensure a plan showing the location of the

sensor is available.

3. Check that the following information

is clearly visible adjacent to the alarm

module:

• In case of alarm instruction.

• Location of the system map in case it

is not installed adjacent to the alarm

module.

• Name and contact number of the person

responsible for operating the system.

• Supplier’s contact name and address.

4. Hand over these Installation, Operating

and Maintenance Instructions.

5. Make the owner aware that it is strongly

recommended to perform a systems

check at regular intervals, at least every six

months.

H. FINAL CHECK LIST

8

COMMISSIONING

Your system should be commissioned

by an authorised AquiTron™ or TraceTek

representative. The system map is a crucial

part of the system and should be located

adjacent to the unit and within the O&M

documents.

Important: Store hardware and

documentation supplied with the MZA in a

secure place for later use (commissioning,

connecting interfaces, operating).

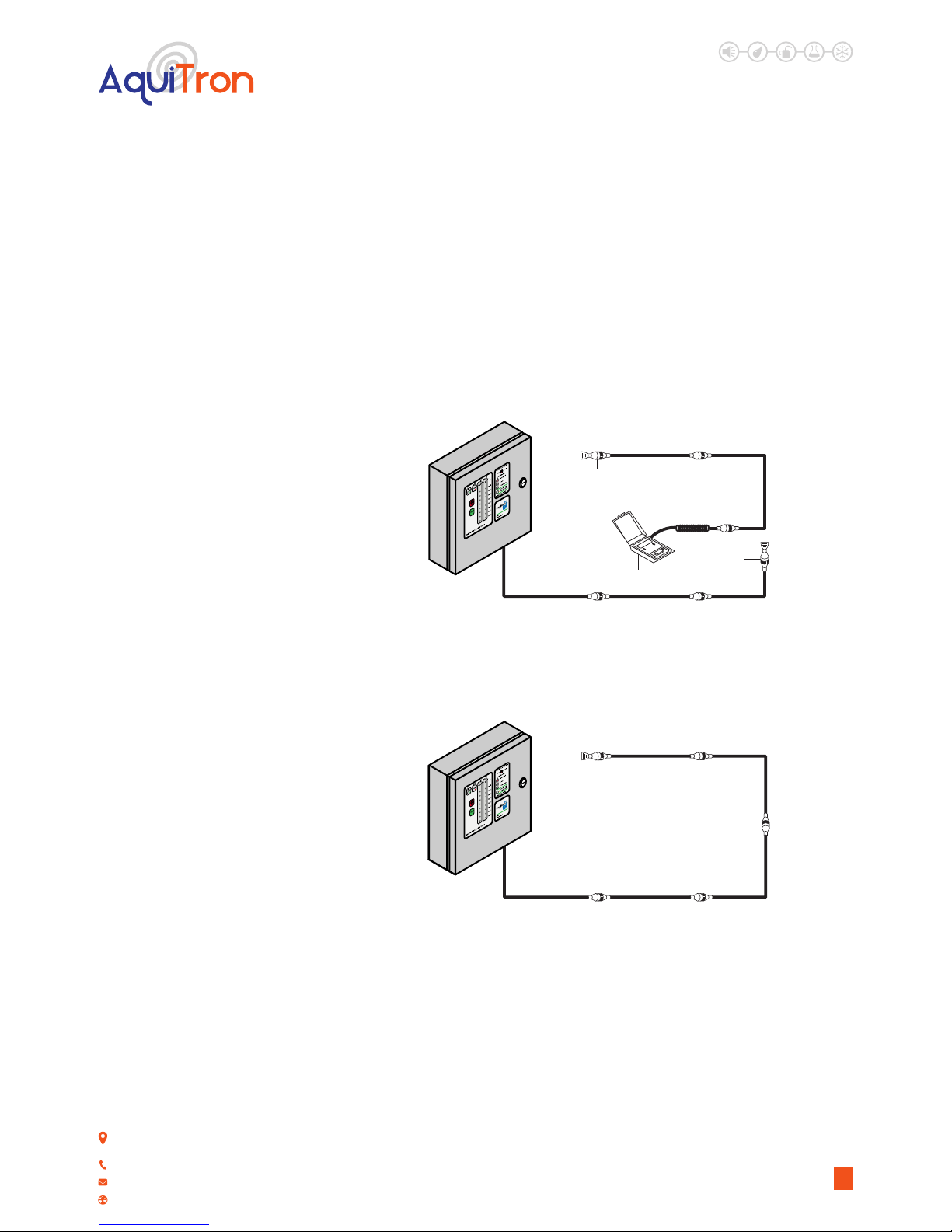

I. INVESTIGATING LEAKS AND FAULTS

If the location of a leak is not apparent, it is often useful to subdivide the leak detection

circuit, as illustrated below. To accomplish this, it is recommend have a TraceTek Portable

Test Box (PTB) and an extra Modular End Termination is used. Contact your local TraceTek

representative to obtain these products. Note that the PTB comes with instructions on how to

use it.

To segment the system (one individual zone) and isolate problems, nd a TraceTek sensing

cable or jumper cable connection at a convenient point somewhere at the center of the

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

9

TraceTek or AquiTron™

Leak detection alarm panel

End termination

TraceTek or AquiTron™

Leak detection alarm panel

End termination

End

termination

PTB

detection circuit. You can then use a PTB to check one portion of the system (to verify circuit

integrity, to detect the presence of liquid, and even to determine its location, as the PTB will give

you an indication in feet or metres to the point of the leak). If you install an end termination on

the other length of cable (going back to the MZA panel), you can use the MZA to check the “front

half” of the sensing circuit.

You can further subdivide the circuit, and even test individual lengths of cables, as shown in the

third diagram below. Even the most perplexing problems can usually be isolated and resolved

using this methodical approach.

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

J. CLEANING THE MODULE

To clean the outside surface, use a damp

cloth or sponge. Do not use solvents or

abrasive cleaners, and do not open the

enclosure while it is wet (it is an electrical

device).

L. FUSE REPLACEMENT

The fuse on the power supply board (item 7

on the internal layout drawing) is a 1600-mA,

250-V. Use no other type of fuse or the MZA

could be damaged or fail to perform properly.

A spare fuse is provided and positioned on

the mother board item 4.

K. STORAGE AND HANDLING

OF SENSING CABLE

M. NOTE ON CABLE

CLEANING

Despite their rugged construction, TraceTek

sensing cables must be handled in a

manner appropriate for a sensing device

or they may be damaged and require

replacement. Therefore, you should follow

some basic rules for storing and handling all

TraceTek sensing cables:

• Store spare cable in its original container

in a clean, dry place until ready for

installation.

• Schedule cable and probe/sensor

installation after all mechanical, plumbing,

and electrical work has been completed.

• Clean the area where the cable is to be

installed, and remove any obvious debris

or other sources of contamination.

• Do not solder or weld near the cable

without providing protection from heat,

solder ux, or weld splatter.

• Do not drop tools or oor tiles on the

cable; sharp and heavy objects may

damage the cable.

• Avoid walking or stepping on the cable.

Provide shielding (for example, a half

shell of plastic pipe) where additional

protection is necessary.

• Do not use tape to secure sensing cable

(some tapes and adhesives absorb

moisture) or use solvents that could

eventually cause an alarm.

• Do not drag sensing cable through

contaminants (such as pipe dope, PVC

cement, solvents, oil, or dirt).

TraceTek TT1000 and TT3000 use a solid

core polymer construction and can usually

be easily cleaned with tap water. In extreme

cases or when large amounts of cable are

contaminated, either cable can be washed

in an ordinary dishwasher. Try a water only

(no detergent) cycle rst and avoid the

heated dry cycle. When placing the cable in

the dishwasher be sure to tightly connect

the male connector on one end to the

female connector on the other. Keep water

out of the connectors.

TT5000 and TT5001 cannot be cleaned

without special equipment. These cables

normally require replacement after

exposure to fuel or solvent.

N. PERIODIC MAINTENANCE

AND TESTING

Recommended Interval: Perform a

functional check per the following procedure

at 6-month intervals. Repair or replace all

damaged wiring and senor cables. There are

no eld repair procedures for the MZA panel.

If the module fails to perform the functional

tests it must be replaced

10

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

O. TROUBLE SHOOTING

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is dirty (TT1000, TT3000).

Action:

Clean cable using water (no solvents, acetone,

white spirit or turps). Dry the cable and

check MZA front panel. Heavily contaminated

cable may require replacement. But if dirt is

accumulating, cleaning and/or replacement

will eventually be required.

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is exposed to occasional water spraying

(TT1000, TT3000)

Action:

It is best to keep the sensor cable at least

1 meter (3 feet) from the outow of any air

conditioner units.

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is in contact with sharp metal edges

(TT1000, TT3000)

Action:

Check the sensor cable for possible points of

contact with sharp edges such as the edges of

drip trays or the pipe threads on adjustable

oor supports, trunking and ducting.

Reposition the cable as necessary or insert a

small piece of insulating material to prevent

the cable from making contact with the metal

edge.

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is pinched (all cables).

Action:

Check the sensor cable for possible pinch

points. TT5000 and TT5001 can be tripped if

tightly bent or compressed by a heavy object.

TT1000 and TT3000 can be tripped by heavy

pressure from a metallic object. Check the

entire cable installation for pinch points and

correct the condition.

Problem:

CABLE BREAK indication but cable appears to

be intact. Possible

Cause:

Loose connections at terminal block.

Action:

Check all terminal block screws for tightness.

To test the module by itself, use two small

pieces of wire to form temporary jumpers

from red to green and yellow to black at the

sensor cable terminal block. This simulates

a very short piece of sensor cable and the

yellow CABLE BREAK LED should go o. If the

MZA cannot pass the jumper wire test it may

require replacement.

Problem:

BMS/PLC or other host system detects a

fault when the MZA is operating in NORMAL

mode.

Possible Cause:

Mains power has cycled. Logic controller has

powered relays incorrectly.

Action:

Press RESET button. This will clear any logic

power up anomalies, and the panel will now

function correctly.

11

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

NORMAL MODE INDICATIONS:

LEAK LED (Red) OFF

CABLE BREAK LED (Yellow) ON

POWER LED ON (Green) ON

ALARM/TROUBLE RELAY NORMAL (de-enrgised)

LEAK MODE INDICATIONS:

LEAK LED (Red) ON

CABLE BREAK LED (Yellow) OFF

POWER LED ON (Green) ON

ALARM/TROUBLE RELAY ALARM(enrgised)

USER ACTION

1. Locate the spill area, investigate the cause of the spill and take necessary repair actions.

2. Clean up in the spill area and clean and dry the cable / probe, if necessary. LEAK LED will turn

o when cable / probe is dried.

CABLE BREAK INDICATIONS:

LEAK LED (Red) OFF

CABLE BREAK LED (Yellow) ON

POWER LED ON (Green) ON

ALARM/TROUBLE RELAY ALARM(enrgised)

USER ACTION

1. Investigate the sensor cable and leader cable for physical damage. Check connectors for

damage. Make repairs or replace components as necessary.

2. CABLE BREAK LED automatically turns o when normal sensor cable continuity is restored.

The Alarm Relay automatically returns to the NORMAL position when cable continuity is

restored.

12

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

13

FIG 8. TERMINAL CONNECTION LAYOUT

SENSO R

RED

GR N

YEL

BL K

Z8

x3

Z7

N/O

CO M

N/C

LEAK

REL AY

x5

SENSO R

RED

GR N

YEL

BL K

Z6

x7

Z5

SENSO R

RED

GR N

YEL

BL K

Z4

x10

Z3

SENSOR

RED

GR N

YEL

BL K

Z2

x12

Z1

31x11x8x

N/O

CO M

N/C

x14

TO P

FA UL T COMMO N

BOTTO M

LEAK COMMO N

N/O

CO M

N/C

LEAK

REL AY

N/O

CO M

N/C

LEAK

RELA Y

N/O

CO M

N/C

LEA K

RELA Y

Important: All information, including illustrations, is believed to be reliable. Users, however,

should independently evaluate the suitability of each product for their application. Aquilar

Limited makes no warranty as to the accuracy or completeness of the information, and

disclaims any liability regarding its use. The only obligations of Aquilar Limited are those in

the Aquilar Standard Terms and Conditions of Sale for this product, and in no case will Aquilar

Limited be liable for any incidental, indirect, or consequential damages arising from the sale,

resale, use or misuse of the product. Specications are subject to change without notice. In

addition, Aquilar Limited reserves the right to make changes – without notication to Buyer

– to processing or materials that do not aect compliance with any applicable specication.

AquiTron is a trademark of AquiTron Limited

Aquilar is a trademark of Aquilar Limited

TraceTek is a trademark of Pentair

AT-MZA

Multi Zone Alarm

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

14

V4 5.2018

Table of contents

Other aquilar Security System manuals

Popular Security System manuals by other brands

Bulldog Security

Bulldog Security 742 Installation and owner's guide

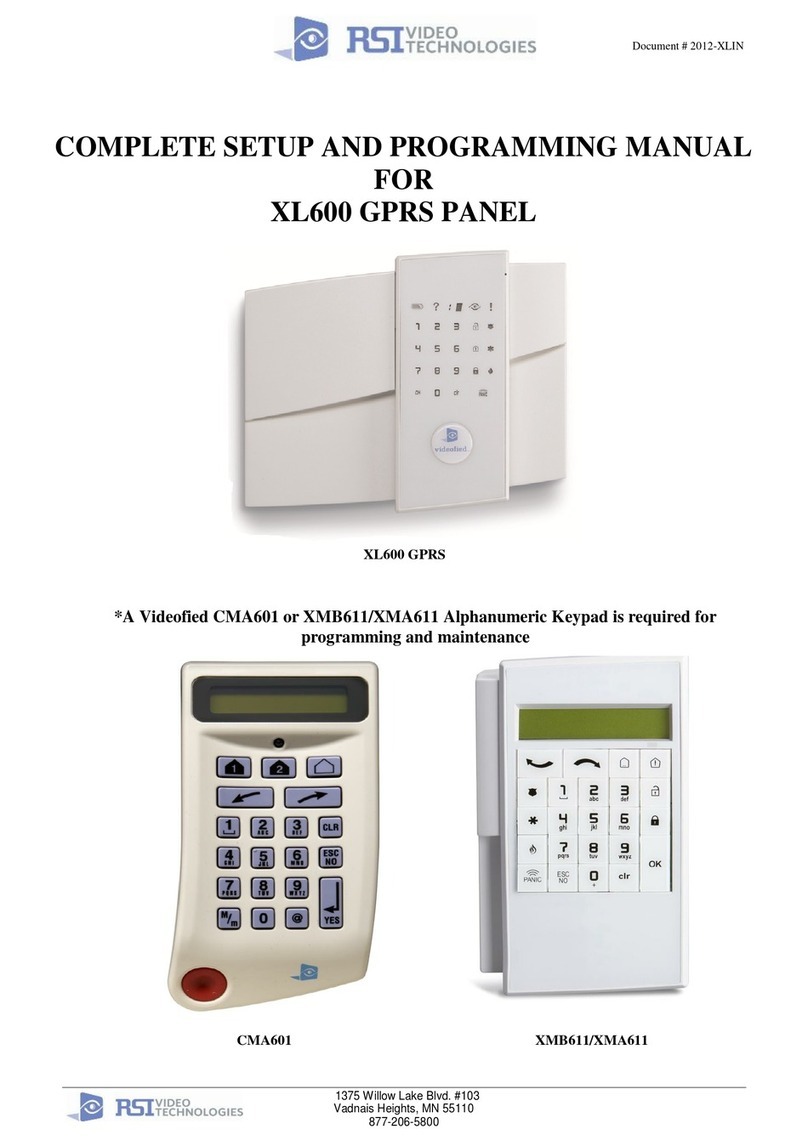

RSI

RSI XL600 COMPLETE SETUP AND PROGRAMMING MANUAL

Vip-Vision

Vip-Vision SLR-A75-4G installation guide

NexxTech

NexxTech 4900424 owner's manual

National Security Systems

National Security Systems Security System owner's manual

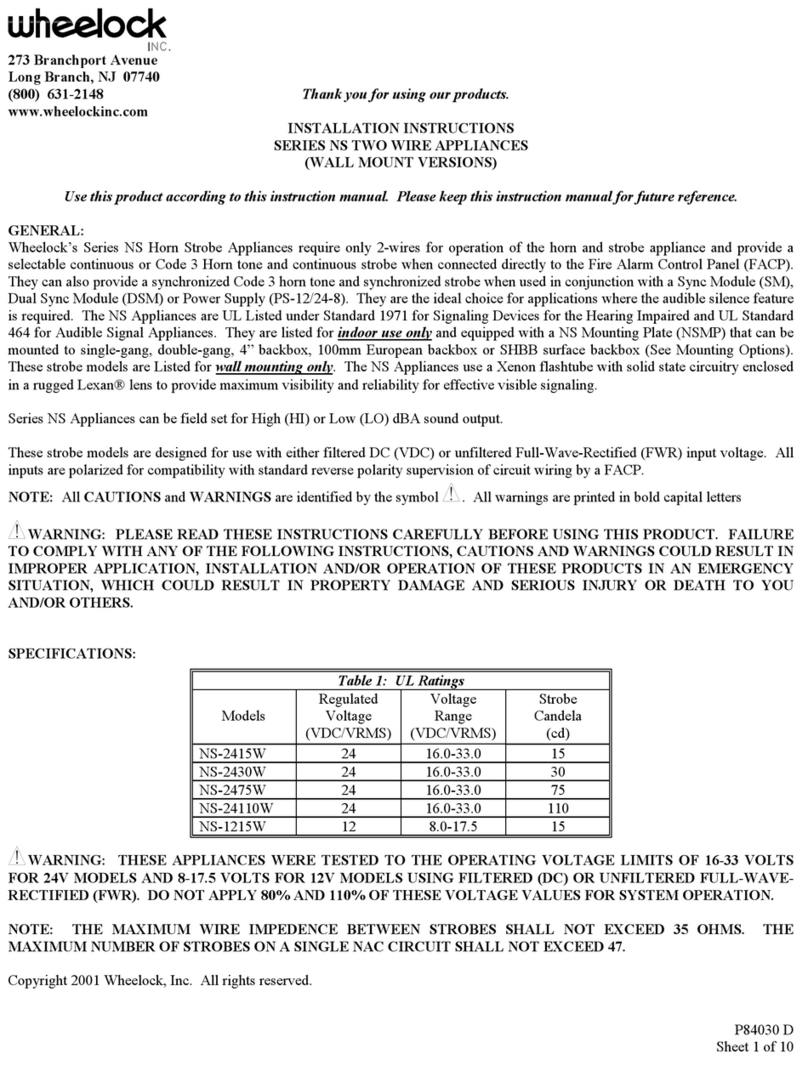

Wheelock

Wheelock NS-1215W installation instructions