ARB AIRLOCKER RD145 User manual

RD145

ROCKWELL 2.5T, 16 SPLINE

AIR OPERATED

LOCKING DIFFERENTIAL

INSTALLATION GUIDE

No liability is assumed for damages resulting in the use of the information contained herein.

ARB Air Locker Air Operated Locking Differentials and Air Locker are trademarks of ARB Corporation Limited.

Other product names used herein are for identification purposes only and may be trademarks of their respective owners.

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA

3137

www.arb.com.au

Table of Contents:

1

1 Introduction

3

1.1

Pre-Installation Preparation

3

1.2

Tool-Kit Recommendations

4

2 Removing the Existing Differential

5

2.1

Vehicle Support

5

2.2

Differential Fluid Drain

5

2.3

Removing the Axles

6

2.4

Marking the Bearing Caps

6

2.5

Removing the Differential Carrier

7

3 Installing the Air Locker

8

3.1

Re-Mounting the Ring Gear

8

3.2

Assembling the Seal Housing

10

3.3

Installing the Carrier Bearings

11

3.4

Drilling and Tapping the Bulkhead Port

12

3.5

Final Air Locker Assembly

13

3.6

Profiling the Seal Housing Tube

14

3.7

Setting Up the Bulkhead Fitting

15

3.8

Bench Testing the Air Locker

17

3.9

Reinstalling the Differential and Axles

17

4 Installing the Air System

18

4.1

Mounting the Solenoid

18

4.2

Running & Securing the Air Line

20

4.3

Connection to the Bulkhead Fitting

21

5 Mounting & Connecting the Electrical System

23

5.1

Mounting the Actuator Switch(es)

23

5.2

Wiring the Actuator System

24

6 Testing & Final Assembly

27

6.1

Leak Testing

27

6.2

Testing the Air Locker Actuation

28

6.3

Filling the Differential

28

6.4

Post-Installation Check List

29

7 Parts List

31

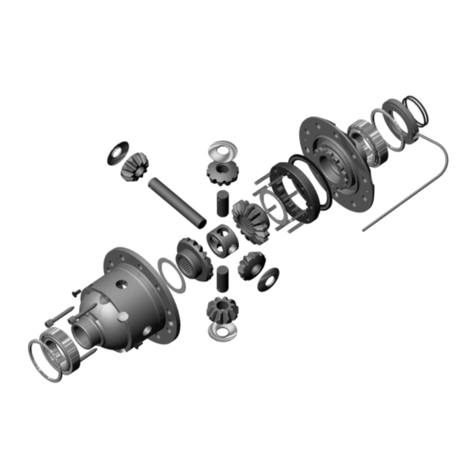

7.1

Exploded Assembly Diagram

31

7.2

Specifications

31

7.3

Itemized Parts List

32

2

1 Introduction

3

IMPORTANT :

BEFORE ATTEMPTING TO DISMANTLE YOUR VEHICLE FOR THIS

INSTALLATION, PLEASE READ THIS INSTALLATION GUIDE IN ITS

ENTIRETY, AS WELL AS ALL APPLICABLE SECTIONS OF YOUR

VEHICLE MANUFACTURER’S SERVICE MANUAL.

1.1 Pre-Installation Preparation

This booklet is to be used in conjunction with your vehicle

manufacturer’s service manual. ARB endeavors to account for every

possible variation in vehicle model when publishing its installation

guides, and guides are updated regularly as new model information

becomes available, however, the rapid and globally varied release of

some vehicles makes it difficult to insure that your vehicle model has

been accurately accounted for. In the case of any technical

discrepancies between this guide and your service manual, we

strongly advise that you adhere to the specifications and techniques

as documented in your service manual.

Although your ARB Air Locker comes complete with all the step by

step instructions you will need to supplement your vehicle

manufacturer’s service manual and install your new differential, ARB

recommends that you have your Air Locker installed by a trained

professional. Many ARB distributors around the world have been fully

instructed in Air Locker installations by ARB, and have gained a wealth

of experience and skill from years of performing similar installations.

Once you begin this installation your vehicle will be immobile until all

steps of the installation are complete. Make sure your Air Locker kit is

the correct model for your vehicle and that it contains all of the parts

listed on back cover of this booklet. Also be sure you have

appropriately equipped yourself with all the necessary tools, parts, and

materials to complete this installation (see section 1.2 Tool-Kit

Recommendations), and that you have allowed for an appropriate

amount of vehicle down time.

HINT : Place a mark inside each of the symbols as

you complete each step. It is very important NOT to

miss any of the steps!

1 Introduction

4

1.2 Tool-Kit Recommendations

Below is a list of tools and supplies you may need to complete this

installation. Requirements for your vehicle may vary. Please consult

your vehicle service manual for additional recommendations.

1.2.1 Tools

Standard automotive sizes (metric and/or imperial) of sockets,

wrenches, Alan keys, and drills.

A standard automotive feeler gauge.

A razor knife to cut the nylon tubing.

An adjuster-nut wrench. (See your vehicle service manual)

A torque wrench. (See vehicle service manual for required torque

range.)

A lubricant drain reservoir.

A 11.2mm [7/16”] drill and ¼” NPT tap for bulkhead fitting

installation.

An automotive bearing puller (2 jawed is recommended) or a

differential carrier bearing puller.

A bearing press or arbor press.

1.2.2 Supplies

Thread lubricant/sealant compound for pressure fittings

(e.g., LOCTITE #567 Teflon paste)

Thread locking compound (e.g., LOCTITE #272)

Either a replacement gasket, or gasket sealant, for your differential

cover.

A sufficient volume of differential oil to completely refill your

housing. (see the ARB Air Locker Operating and Service Manual

for recommended lubricants)

A soap and water mixture to test for air leaks.

2 Removing the Existing Differential

5

2.1 Vehicle Support

Safely secure the vehicle on a hoist. We recommend supporting

the vehicle on a chassis hoist to keep the differential area at a

convenient working height and to leave the wheels and axles free

to be rotated and removed.

Once supported off the ground, release the parking brake and

leave the vehicle in neutral. Chock the wheels if necessary.

2.2 Differential Fluid Drain

HINT : This is a good time to check for metal particles in

your oil, on your drain plug, or in the bottom of the

housing which may indicate a worn bearing or

differential component.

Clean around the drain plug and differential housing to prevent dirt

from entering the differential.

Position a fluid drain reservoir under the differential, remove the

drain plug and completely drain all differential oil from the housing.

2 Removing the Existing Differential

6

2.3 Removing the Axles

IMPORTANT :

Collision damage or heavy off-road use of your vehicle in the past may

have resulted in some degree of bending in the axle. Any misalignment

of the axle tubes may result in excessive wear and/or failure of your

differential and axle shafts. ARB strongly recommends that you have

your axle assembly inspected for concentricity and straightness before

installing your Air Locker.

Remove the wheels, and both axle shafts according to your vehicle

manufacture’s service manual.

NOTE : The axle oil seals are delicate and can be easily

damaged. Support the weight of the axle shaft when

drawing them out of their sockets in the housing.

Disconnect the drive shaft from the flange of the differential.

Remove the third member from the differential housing. Refer to

your vehicle’s service manual.

2.4 Marking the Bearing Caps

Using a pointed center punch, gently mark the bearing caps in a

way that will enable you to know which cap is ‘LEFT’ and which cap

is ‘RIGHT’, which way is ‘UP’ and which way is ‘DOWN’. (Fig.1.)

HINT : Many installers choose to make one punch mark on

the left hand side of the left hand bearing cap and one

similar punch mark on the housing at close proximity to

the cap mark. The right hand side is then designated

with two punch marks on the right hand side of the cap

and two similar punch marks on the housing.

Figure

1.

2 Removing the Existing Differential

7

2.5 Removing the Differential Carrier

Remove both adjuster nut locking tabs.

Loosen both bearing caps.

Using the appropriate adjuster nut wrench, loosen the adjuster nuts

at least half a turn.

Remove the bearing caps.

Carefully remove the differential carrier.

NOTE : The differential carrier is heavy and quite difficult to

handle when covered in oil. Take care not to drop it.

3 Installing the Air Locker

8

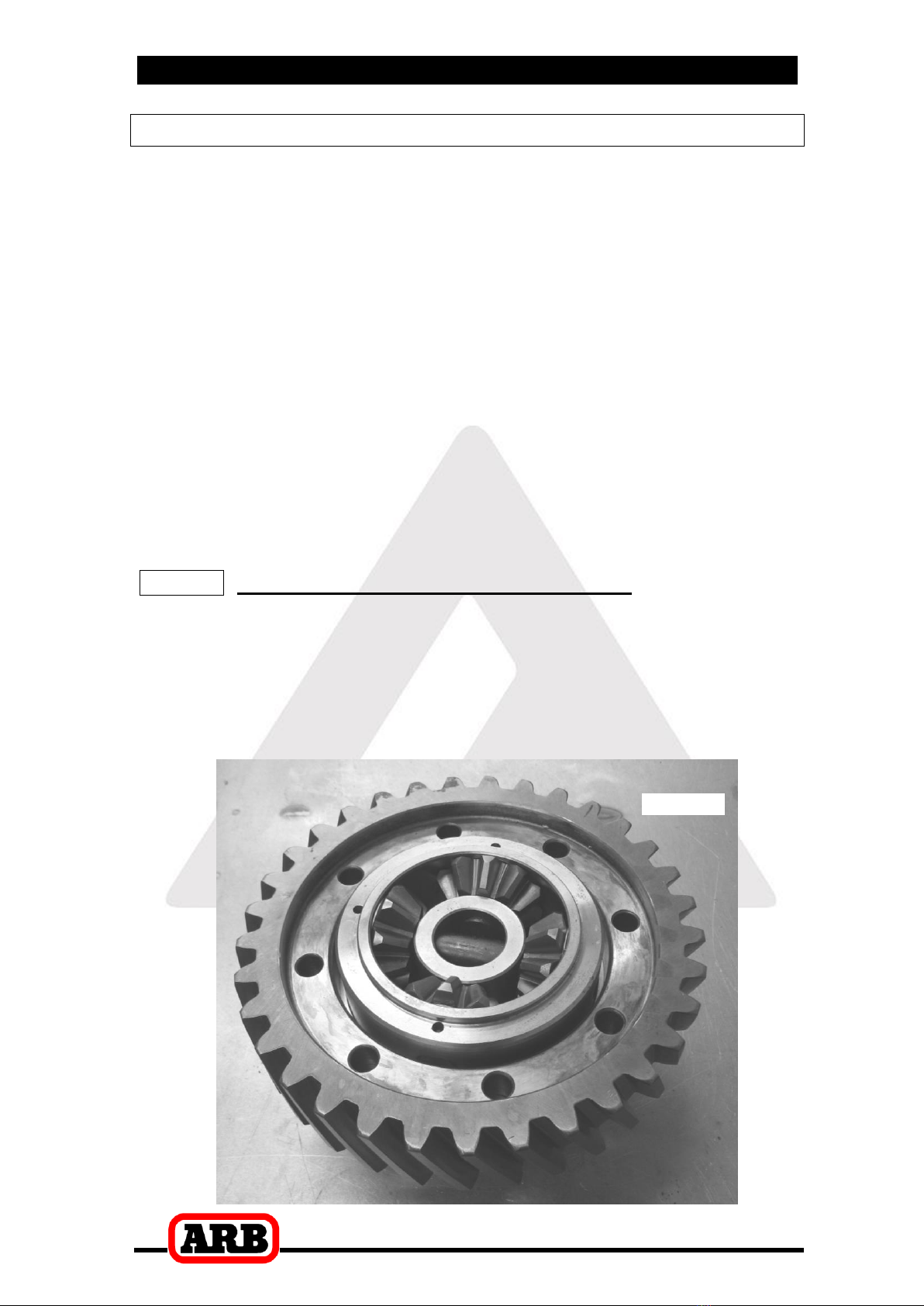

3.1 Re-Mounting the Ring Gear

Remove the bolts that hold the ring gear in place.

Using a plastic or copper hammer, tap in a circle around the ring

gear to separate it from the two halves of the original differential

carrier.

Cut the cable ties holding the two halves of the Air Locker together

and separate the case and flange cap.

Apply a thin film of high pressure grease to the outside diameter on

the case of the Air Locker to prevent seizing.

Thoroughly clean any thread locking compound or other foreign

matter from the holes of the ring gear, the threads of the ring gear

bolts, and the mating surfaces between the ring gear and the Air

Locker flange.

Heat the ring gear to between 80 and 100C [175 - 212F] in hot

water or in an oven to slightly expand the gear and facilitate

assembly.

NOTE : NEVER HEAT GEARS WITH A FLAME! This could

damage the hardened surface of the gear and result

in premature wear or failure.

Dry the gear and bolt holes with compressed air (if wet).

Install the ring gear onto the case of the Air Locker by aligning the

bolt holes and then gently tapping it around in a circle with a soft

mallet (Figure 2.).

Figure

2.

3 Installing the Air Locker

9

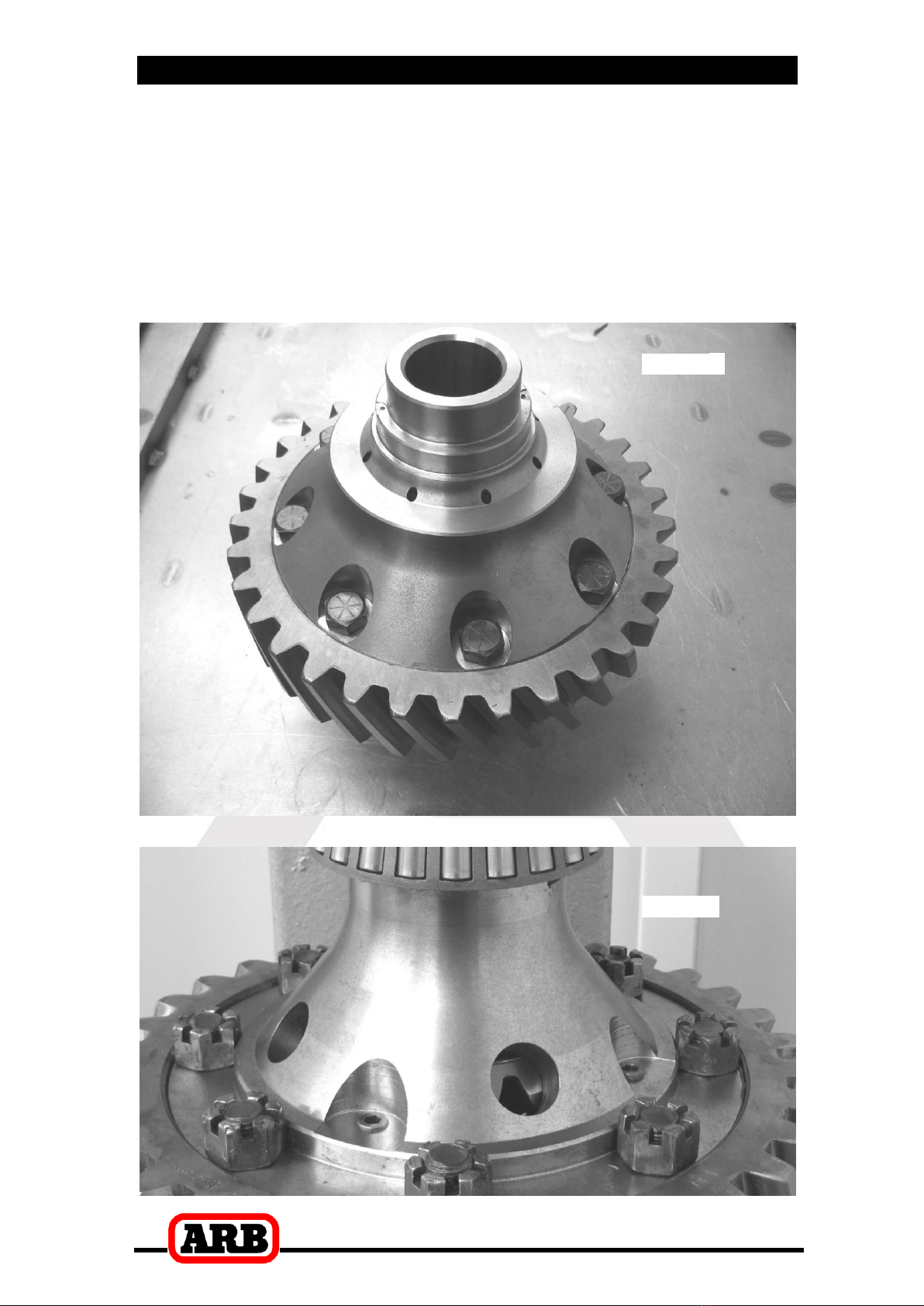

Apply a thin film of high pressure grease to the ring gear diameter

of the flange cap and install the flange cap into the ring gear.

Apply a thread locking compound to the thread of each ring gear

bolt before inserting into the Air Locker.

Install the nuts and tighten the ring gear bolts in a star pattern with

a torque wrench according to your vehicle manufacturer’s specified

torque (Figure 3.). The nuts will be held captive by the machined

face on the case (Figure 4.).

Figure

3.

Figure

4.

3 Installing the Air Locker

10

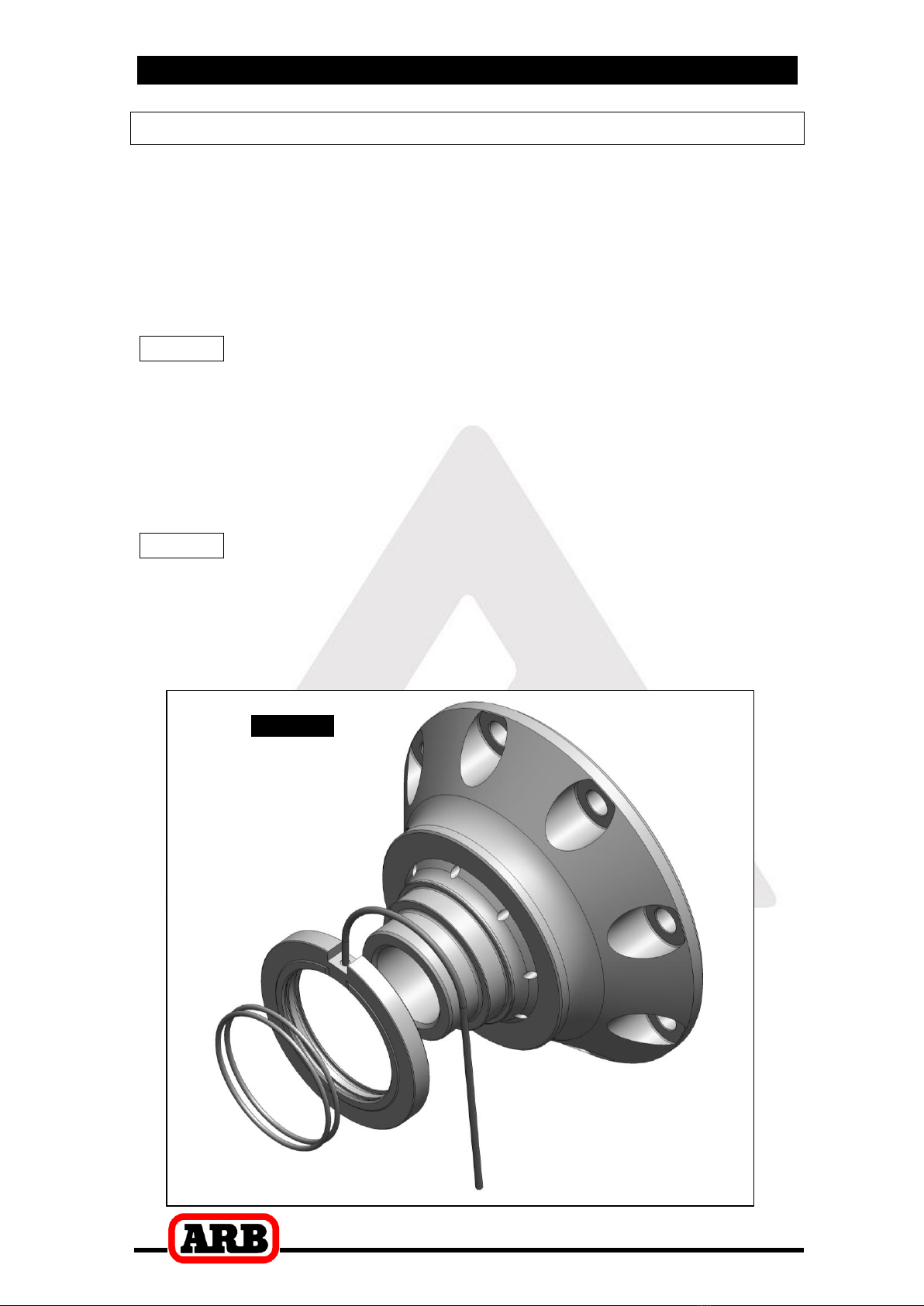

3.2 Assembling the Seal Housing

Make sure the grooves and airway of the seal housing are clean

and free from any contaminants (e.g. water, dirt, metal filings, etc.).

Inspect the seal housing O-rings (supplied) for dirt, damage or

other conditions which might cause leaks.

Generously lubricate the O-rings with oil prior to assembly, then

insert them into the grooves of the seal housing.

NOTE : When assembling the O-rings, be careful not to leave

them twisted when seated in the grooves as this could

cause excessive wear and leakage.

Lubricate the seal housing running surface on the Air Locker carrier

with oil.

Carefully install the seal housing by sliding it all of the way onto the

seal housing running surface with a gentle twisting motion.

NOTE : A twisting motion (i.e., a slight rotation while pressing

the seal housing on) will allow the O-rings to engage

gently and prevent them from twisting. Twisted

O-rings will result in pre-mature O-ring wear and oil

contamination in the air system due to the helical

shape formed by the O-ring mould line.

Figure

5.

3 Installing the Air Locker

11

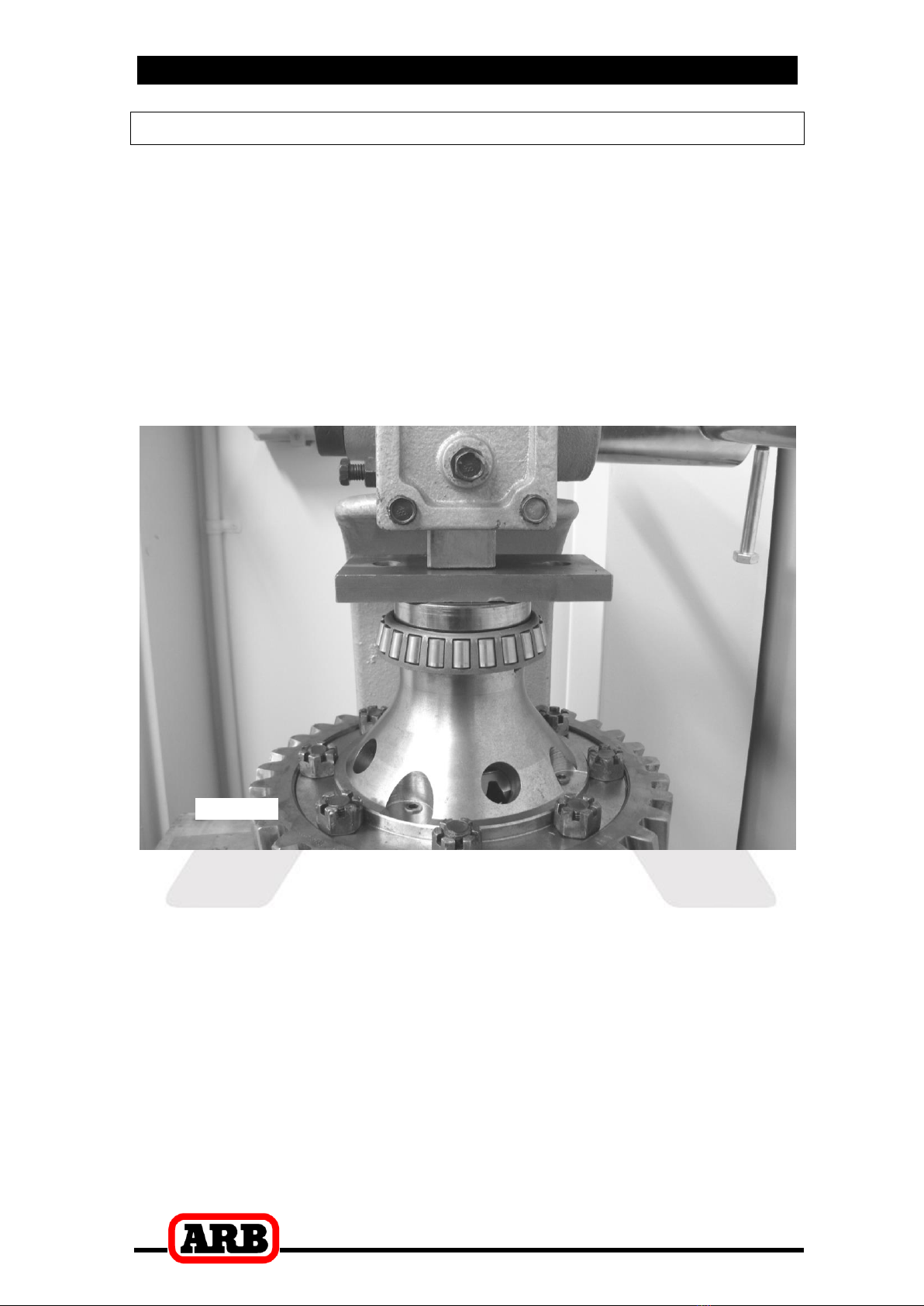

3.3 Installing the Carrier Bearings

If the tapered roller bearings from the original differential carrier are

to be reused, then remove them with an automotive bearing puller

and inspect them for damage and/or wear and replace them if

necessary.

Apply a thin film of high pressure grease to both bearing journals of

the Air Locker to prevent seizing.

Using a bearing press or arbor press, press one of the bearing

cones onto the Air Locker bearing journal, with the seal housing in

place, until the bearing seats firmly against the bearing journal

shoulder. (As shown in Figure 6.)

Figure

6.

Invert the Air Locker and press the other tapered roller bearing

cone onto the opposite bearing journal of the differential carrier until

the bearing seats firmly against the bearing journal shoulder.

3 Installing the Air Locker

12

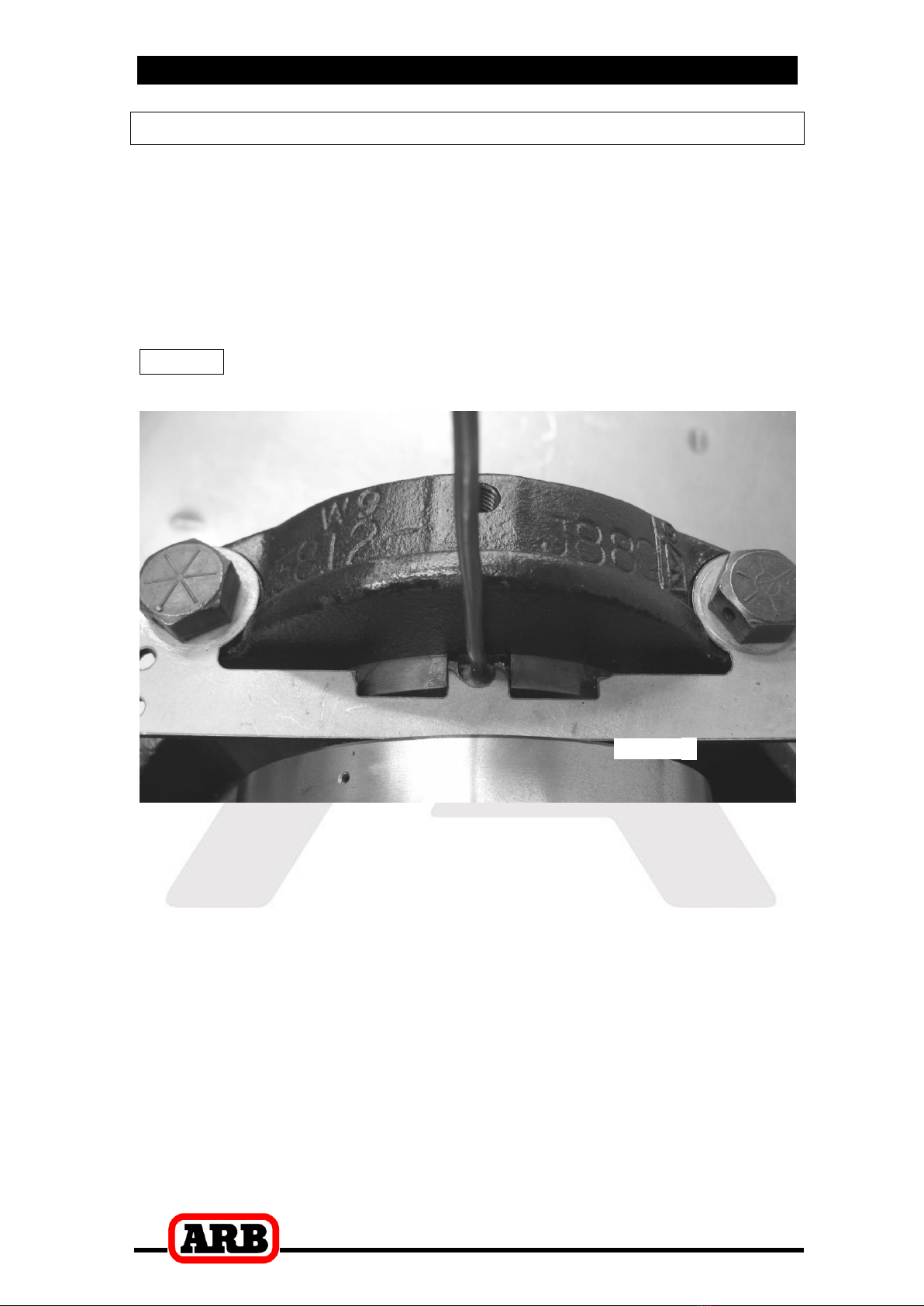

3.4 Drilling and Tapping the Bulkhead Port

An airline port must be drilled and tapped through the axle housing

casting to mount the bulkhead fitting into.

Cover the worm gear area with rags to protect from metal filings.

Mark a spot on the axle housing casting in the position shown in

Figure 7.

Figure

7.

Drill through the housing square to the inside surface using a

11.2mm [7/16”] drill.

Tap the hole from the outside using a ¼” NPT pipe tap.

Remove any sharp edges from the hole that may chip-off and fall

into the housing.

3 Installing the Air Locker

13

3.5 Final Air Locker Assembly

Reinstall the Air Locker into the axle housing.

Install the bearing caps oriented as they were marked before they

were removed.

Rotate the seal housing so the slot and the tube are pointing

straight out of the axle opening. Then install the seal housing

bracket with the tab locating in the slot as shown in Figure 8.

NOTE : Washers are to be left off the seal housing side

bearing cap bolts.

Figure

8.

Insert the bearing cap bolts and finger tighten. It is not necessary to

torque them down at this time.

Tighten the adjuster nuts to give the carrier bearings the required

preload.

3 Installing the Air Locker

14

3.6 Profiling the Seal Housing Tube

Without using sharp, jagged tools such as pliers (your hands are

the best tool for this job), gently bend the seal housing tube so that

it runs in a loop beside the flange cap and out through the tapped

bulkhead port as shown in Figures 9., 10., and 11.

NOTE : It is a good idea to cable tie the tube to the seal

housing bracket to keep it from contacting anything

inside the housing.

Figure

9.

Figure

10.

3 Installing the Air Locker

15

Figure

11.

3.7 Setting Up the Bulkhead Fitting

Trim the seal housing tube that is extended through the bulkhead

port to approximately 8mm [5/16”] long using an automotive brake

line tubing cutter.

NOTE : Never use a hacksaw to cut the seal housing tube as

this will leave metal filings in the air system.

Apply thread sealant to the outside threads of the bulkhead body.

Screw the bulkhead body into the tapped hole, and lightly tighten

using a 14mm [9/16”] spanner.

Wipe the area clean of any excess thread sealant (inside and

outside of the housing).

Insert the free end of the seal housing tube into the bulkhead fitting

until it protrudes approximately 8mm [5/16”] through the other side.

From the outside of the housing, assemble one of the small O-rings

over the top of the short length of seal housing tube protruding

through the bulkhead fitting.

Install the brass spacer.

Install the second small O-ring after the spacer.

While holding the seal housing tube into the bulkhead fitting, insert

the chamfered end of the center compression nut over the

extended tube as shown in the assembly diagram (Fig. 12.), and

screw it into the bulkhead body, and tighten using Pozidriv #3

screwdriver.

3 Installing the Air Locker

16

Figure

12.

NOTE : Make sure the seal housing tube is all of the way into

the center compression nut while you are tightening

it.

NOTE : Firmly tighten the center compression nut so that a

good seal is formed around the tube.

3 Installing the Air Locker

17

3.8 Bench Testing the Air Locker

To test the Air Locker, when 620kPa [90 PSI] shop air is applied to

the seal housing tube, the Air Locker should engage.

Check all fittings and the seal housing for air leaks.

Rotate the differential carrier by turning the pinion flange whilst

applying air pressure.

NOTE : An accurate way to test for air leaks is to fit a shut-off

valve to an air pressure gauge (Available as ARB part

#ALTG01). Charge with shop air until 620 KPA [90 PSI]

is reached, shut the valve off, disconnect the air hose,

and watch to see if there is any drop in pressure. Any

gradual pressure drop indicates an air leak. (Fig.13.)

Figure

13.

If a leak is found to be present, spray a soap and water mixture

onto the bulkhead air fitting. Bubbles should appear at any leak

points.

NOTE : Do not spray this soapy mixture inside the differential.

Check that leaky fittings have been adequately tightened.

Disassemble, clean threads, and reapply thread sealant if leaking

persists.

If a leak is found at the seal housing, carefully remove and refit. Be

very careful with the O-rings and check they have not been

damaged during installation.

3.9 Reinstalling the Differential and Axles

Reinstall the differential and axles as per your vehicle

manufacturers service manual.

4 Installing the Air System

18

4.1 Mounting the Solenoid

4.1.1 Connection to an ARB Air Compressor (Fig.14.)

Remove one of the 1/8” BSP plugs from its port in the compressor

manifold.

Apply Teflon paste to the 1/8” BSP nipple on the solenoid and

insert it into the port and tighten. The solenoid should be rotated

into a position which does not obstruct any other ports on the

compressor tank.

NOTE : The coil and stem of the solenoid can be removed to

make installation easier.

NOTE : The solenoid is marked with two #1 ports. If space is

tight, a second solenoid can be “daisy-chained” off

the first one by removing the plug from the redundant

#1 port and screwing the nipple from the second

solenoid into it (Fig. 14.).

NOTE : The solenoid exhausts compressed air through the

center of the black retaining cap when the Air Locker

is disengaged. Make sure this orifice cannot be

obstructed.

Assemble the 6mm push-in fitting into the solenoid outlet port

(stamped “2”) and hand tighten.

Figure

14.

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB 3444070 User manual

ARB

ARB Air Locker RD111 User manual

ARB

ARB 1780500 User manual

ARB

ARB AIRLOCKER RD132 User manual

ARB

ARB 3432050 User manual

ARB

ARB 3434040 User manual

ARB

ARB RD121 Operating and maintenance instructions

ARB

ARB AIRLOCKER RD142 User manual

ARB

ARB INTENSITY SOLIS User manual

ARB

ARB AIRLOCKER RD109 User manual

Popular Automobile Accessories manuals by other brands

Racelogic

Racelogic Speed & Route Profiler manual

Offroad Animal

Offroad Animal PR-JGC-WK2-11-ASM0 FITTING INSTRUCTION

Whelen Engineering Company

Whelen Engineering Company SAK45 installation guide

tams elektronik

tams elektronik FCS-4 manual

RJ Power

RJ Power REV-CC3000 user guide

Code 3

Code 3 Pursuit 25 Series installation manual