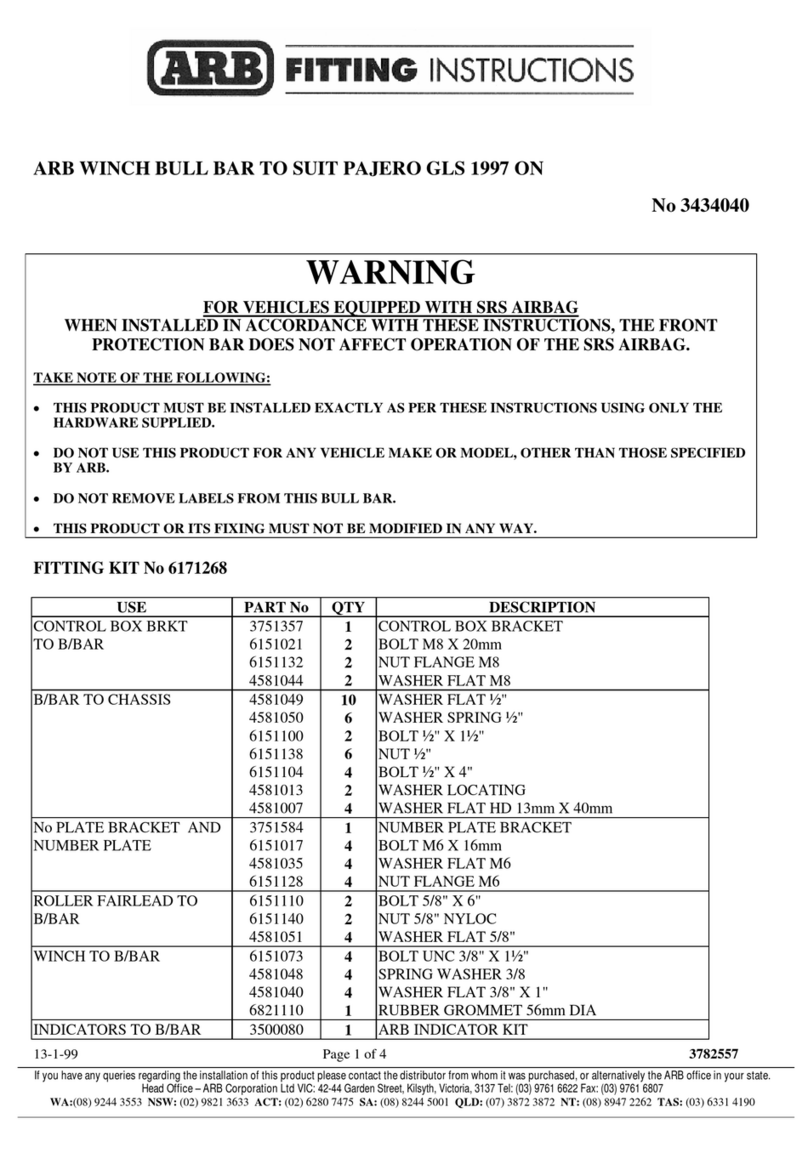

ARB 6174921 User manual

10-02-2020 Page 1 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

DUAL CAB CLASSIC CANOPY

Isuzu DMax / GM Colorado 2012+

Dual Cab Canopy

FITTING KIT: 6174921, SEAL KIT: 6171422, FRONT RAIL: 668PD046

! PLEASE PROVIDE A COPY OF THESE INSTRUCTIONS TO THE CUSTOMER !

IMPORTANT:

Vehicle bodies and vehicle specific installation can vary, so please read the following instructions as

they refer to important information, which could affect the quality of the final installation.

It is advisable to have the canopy fitted by an authorised dealer.

The majority of installation can be completed by one person, (however, at least 2 people will be

required to lift the canopy onto the vehicle).

FITMENT:

For Bed Liners, additional time for fitting is required and trimming of bed liners is required. Fitting with

under rail bed liners is recommended ONLY (ARB part number KUL1359 or Sport guard part

number 10051584).

In addition, it will suit Isuzu Genuine accessories under rail bed liner 94778436.

Cabin Guards and Sports Bars must be removed prior to canopy fitment. These components can

be returned to the customer if required.

When fitting the ARB canopy vent, fitment of the vent is easier prior to fitting the canopy to the

vehicle and before internal frame installations. The vent must be fitted to the front of the canopy

if a roof rack is to be fitted.

CARE OF YOUR CANOPY:

Please refer to the “owner’s manual supplement” to be given to the purchaser on installation, and to

details referred to in the second last page of these fitting instructions.

10-02-2020 Page 2 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

Hearing protection

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a potentially hazardous

situation it is suggested that protective safety gear be worn or a safe work procedure be employed. If these notes and

warnings are not heeded, injury may result.

TOOL LIST FOR FITMENT:

Torque Wrench 0-25Nm

Sockets ¼”, 10 & 13mm, socket extension bar

and driver

Spanners, ratchet type, 8, 10 and 13mm.

T30 Torx Driver

Tape measure

150mm ruler

Power or pneumatic drill

Drill bits 5mm, 6.5mm, 12mm, 14mm

12mm deep drill stops for 5mm and 6.5mm drill

bits.

Knife

Sharp scissors

File or sheet metal de-burring tool

Metal primer touch up paint

Engineer’s scribe

Sheet metal vice grip clamp

Quicklock G clamp

Centre punch

Silicon Caulking Gun

Neutral cure Non-Acetic Silicon

Phillips head screwdrivers

Flat blade screwdrivers

Side Cutters

Wire stripping tool

Non-permanent marker

Electrical tape

Masking tape

Plastic Squeegee

Cleaning cloths / rags

Angle grinder and cut off wheel

Cable ties 6 off 450mm long (not supplied)

Cable ties 8 off 200mm long (not supplied)

FITTING THE CANOPY IS UNDERTAKEN IN THE FOLLOWING STAGES:

1. Removing any sports bars & bed liners and sealing the tub

2. Fitting the tub mounting brackets. (Note details of fitting with bed liners refer to Section 7)

3. Fitting main seal before the canopy is fitted.

4. Fitting the canopy to the vehicle

5. Wiring of the canopy to the vehicle

6. Fitting the bed liners

7. Owner’s manual supplement

8. Fitment check list

NOTE: DURING THE INSTALLATION IT IS NECESSARY TO DRILL SOME HOLES THROUGH THE VEHICLE’S

TUB SHEET METAL. IT IS RECOMMENDED THAT THESE ARE DE-BURRED AND THE RUST

INHIBITOR THAT IS PROVIDED BE USED TO AVOID RUST & ANY SWARF LEFT OVER SHOULD BE

CLEANED FROM THE TUB.

10-02-2020 Page 3 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

!! IMPORTANT !! other than specifically specified in this instruction

REQUIRED SCREW TORQUES: M6=9Nm M8=22Nm

Screw torques must be adhered to avoid warranty issues and should be checked at vehicle service intervals.

THE FITTING KIT CONSISTS OF:

Packed under the canopy are:

668PD046 Front Mount Rail

Part No

Picture

Qty

Description

1. 6174921

MAIN

CANOPY

HARDWARE

KIT

6821135

2

TUBE CONVOLUTED M7 BLK 250mm LONG

668PB014

1

1650 x 26 x 6 FOAM TAPE

665037

1

ROLL- CLEAR TAILGATE PROTECTION TAPE

30MM WIDE

6821132

2

GROMMET 3/8 ID (ONE FOR SHEET METAL

SECOND ONE USE WHEN FITTING

BEDLINER)

665076

3

BUMPON STRIP OF 5 PIECES

665505

1

RUST INHIBITOR SACHET

665044

1

PRIMER STICK

180701

1

SCOTCH LOCK (14-18 AWG)

6821134

1

FUSE HOLDER BLADE TYPE

6821273

3M

WIRE 0.75MM RED CUT 3 METRE

6821127

1

3 AMP BLADE FUSE

CR07

0.5M

7MM CONVOLUTED TUBE BLACK|(BULK)

668PB010

1 Pair

TUB SEALING BLOCK - FOAM

668PB023

1 PAIR

REAR SEALING PAD –FOAM TAPE

6151625

12

M8 x 25 TORX PAN HEAD SCREW - BLACK

10-02-2020 Page 4 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

4581303

12

M8 x 25.4 x 3mm WASHER - BLACK

6151546

8

M8 x 25 BLACK HEX HEAD SCREWS

4581307

16

M8 X 20 X 2mm FLAT WASHER - BLACK

6151212

8

M8 X 1.25 BLACK NYLOC NUT

6151213

14

M6 X 20mm BLACK HEX HEAD SCREWS GD

8.8

4584310

8

M6 X 25 X 2.8mm FLAT WASHER BLACK

4581082

6

M6 x 20 x 1.2mm FLAT WASHER - BLACK

4581287

4

M6 x 2.5 x 1.6mm SPRING WASHER - BLACK

6151173

10

M6 WIZZLOCK FLANGE NUTS - BLACK

668AQ010

2

BRACKET –NUT PLATE

6250026

2

18 OD x 6.5 ID x 6 SPACER - BLACK

6250027

12

18 OD x 8.5 ID x 6 SPACER - BLACK

6609087

2

RIVET POP 3/16” DIA GRIP 4.8-11.1

668PM005

1 Pair

PAIR OF RUBBER SELF-ADHESIVE TUB

CORNER SEAL BRIDGES

3759852

2

CENTER TUB MOUNT BRACKET

6582445

2

CANOPY CLAMP - FRONT

3750205R

1

BRACKET REAR CORNER RH

3750205L

1

BRACKET REAR CORNER LH

3759968R

1

BRACKET RH FRONT TUB MOUNT D-MAX

3759968L

1

BRACKET LH FRONT TUB MOUNT D-MAX

3759969R

1

BRACKET RH REAR TUB MOUNT D-MAX

3759969L

1

BRACKET LH REAR TUB MOUNT D-MAX

2. 6171422

CANOPY SEAL

KIT

9009177

5 M

BEDRAIL SEAL

6602018

2

ALCOHOL WIPES

10-02-2020 Page 5 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

SECTION 1: PREPARING THE VEHICLE TUB –REMOVAL OF SPORTS BARS & BED LINERS

AND SEALING THE TUB.

1.1) Remove any sports bars fitted on the front bed rail of the vehicle’s tub.

1.2) The sports bar will need to be removed if fitted and returned to the customer if requested to do so.

1.3) Remove and retain all bed liner components and tie down hook hardware.

SEALING THE VEHICLE’S TUB

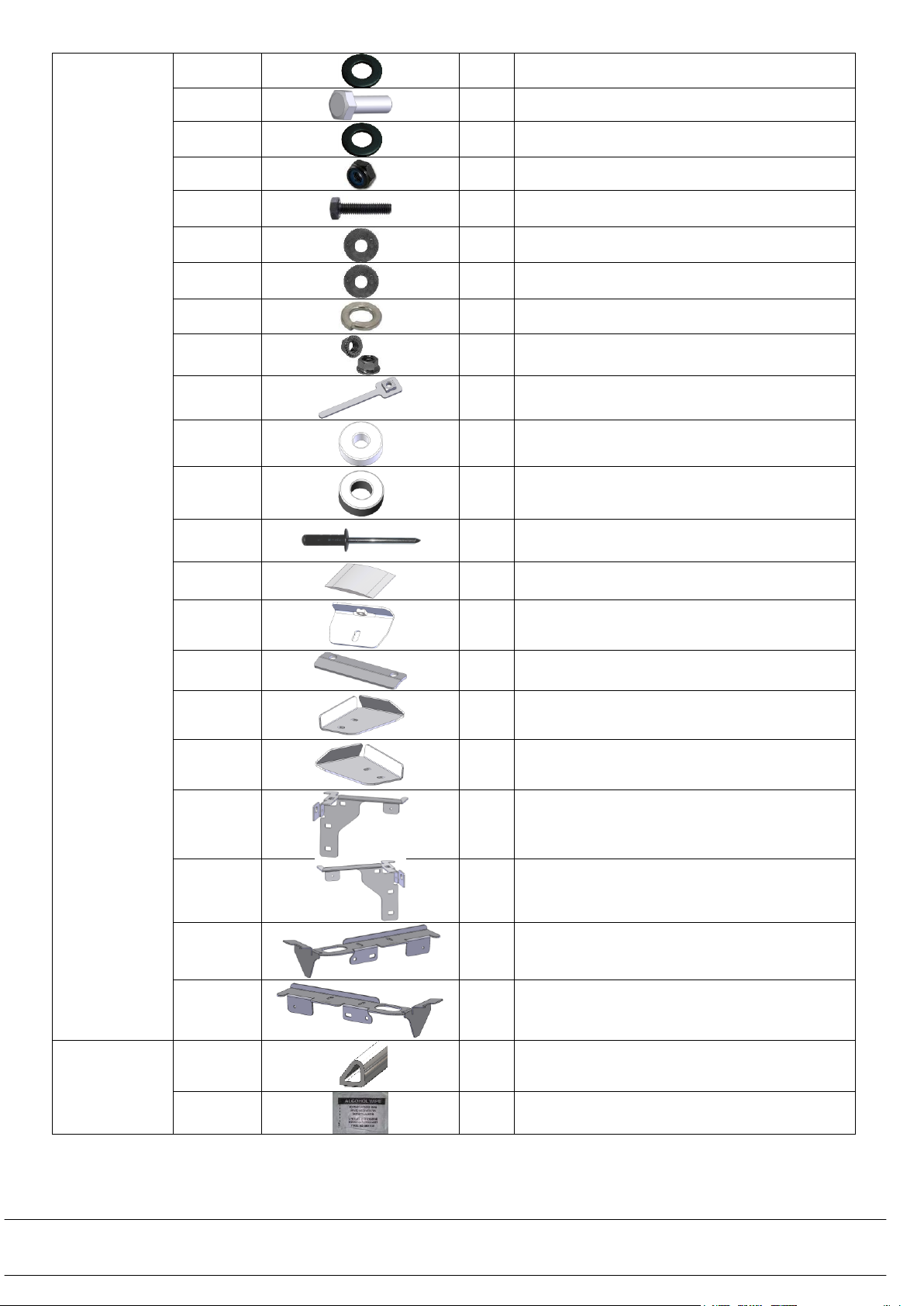

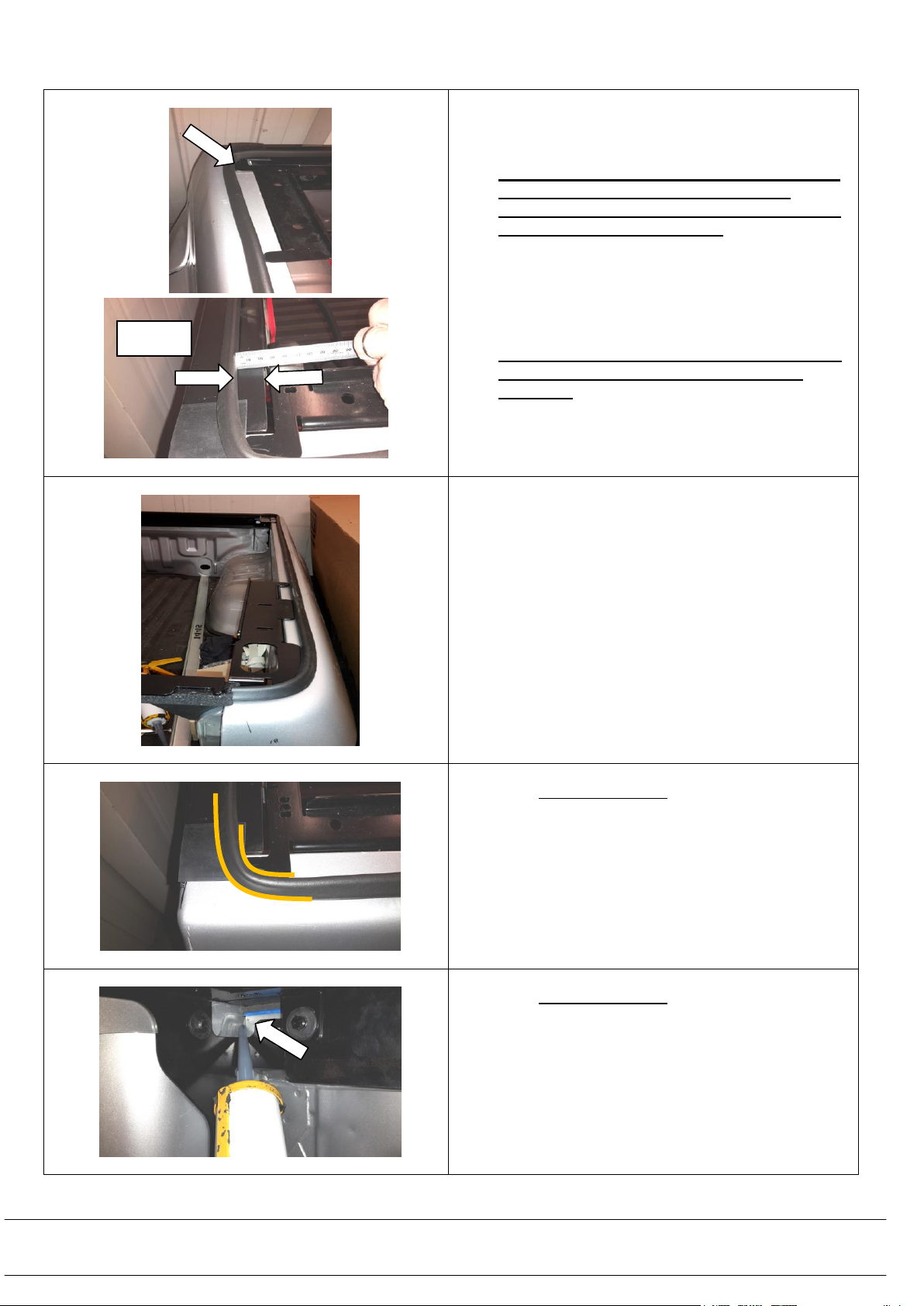

NOTE:

The front corners of the tub where the arrows are

shown are not sealed ex-factory on both sides. It is

necessary to seal these areas before the canopy is

fitted.

(Tub shown removed from vehicle for clarity)

1.4) Inside of the vehicle’s tub side rail at front corner,

locate the hole in the side rail in the tub and push

one of the foam blocks (668PD010) into it in the

following orientation. The foam block is

50x30x75mm. With the block sitting flat on its

50x75mm face, push it up under the side rail of the

tub and push it forward. Locate the rear edge of the

foam block so it snaps in place.

Repeat this on the opposite side.

Inside front corner of tub

Outside front corner of tub

Push foam block up and forwards into the hole in

front corner under side tub rail.

Align rear edge of the foam block so it snaps into the

edge of the sheet metal up under the front tub

corner.

10-02-2020 Page 6 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

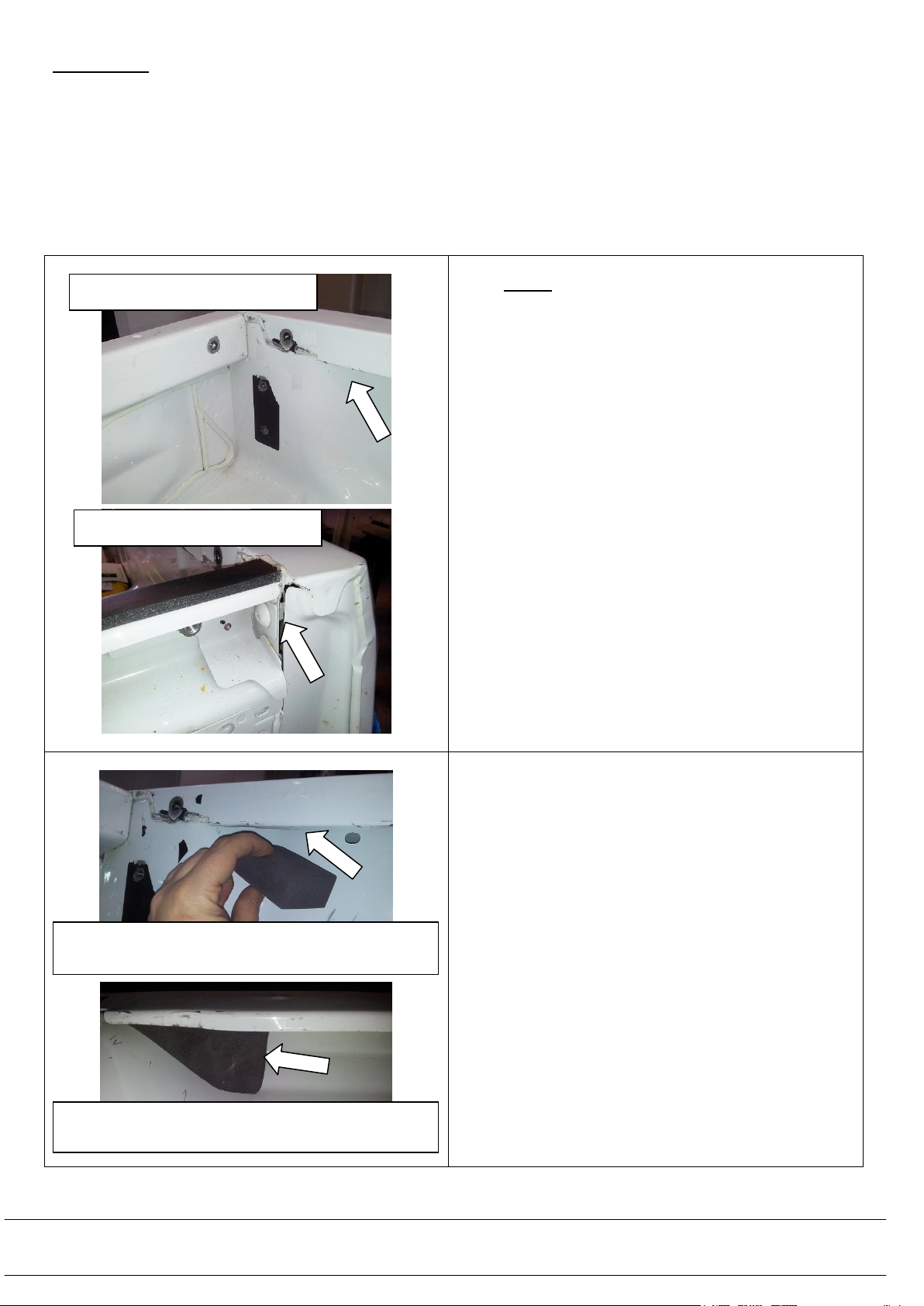

Cover these holes and trim tape here at join

between front rail and side rail of vehicle’s tub.

Tightly butt the tape to this join.

1.5) Spray water using a spray bottle around the foam

block to aid in applying silicon cleanly. Then apply

neutral cure silicon around all edges of the foam

block where it contacts the tub sheet metal and

clean up.

Repeat this on the opposite side

SECTION 2: FITTING THE CANOPY TUB MOUNTING BRACKET SYSTEM

IF BED LINERS ARE TO BE FITTED, REFER TO SECTION 7 PRIOR TO FITMENT

2.0) Clean the front tub rail at the back of the vehicle’s

cabin with Isopropyl Alcohol and a lint free rag.

Starting from the inside edge of the side tub rails,

apply soft foam tape (668PB014) seal along the top

face of the front of the vehicle’s tub, so that it

covers the upwards facing holes. Trim tape level to

butt up to the inside of the side tub rail on the

opposite side.

2.1) Apply neutral cure silicon to the ends of the foam

tape on both sides of the tub, and spatula this down

level to the top of the foam tape.

It is important that the area between the tape and

the sheet metal is also well sealed on the vertical

end faces of the foam tape about the width of the

tape, in front and behind the tape.

Spray water using a spray bottle, down the front

internal corner junction of the tub, to aid in applying

silicon cleanly. Then apply neutral cure silicon

around all sheet metal panel gaps and clean up.

Repeat this on the opposite side.

See next page.

10-02-2020 Page 7 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

2.2) To a pair of front corner tub mounting brackets

(3759968R&L), apply self-adhesive bumpons

(665076) to the two tags on each bracket. These

legs are to sit with the bumpons face down touching

the top edge of the vehicle’s tub once the bracket is

fitted

IF FITTING BED LINER GO TO SECTION 6.0

2.3) Place in the LH front corner of the tub the front tub

mounting bracket (3759968L) fit screws to the three

holes on the side of the tub and Tighten to 22Nm

Repeat on the opposite side using the opposite

hand tub mounting bracket

2.4) Using a 6.5mm drill fitted with a 12mm drill stop to

prevent drilling into the outside tub sheet metal

skin, drill into the rear hole in the front corner

bracket and through the flange on the tub sheet

metal.

Apply rust inhibitor around the hole.

2.5) Insert into the hole an M6 x 20mm (6151213) Hex

Screw with M6 x 25mm Flat Washer (4584310)

under the head and M6 Flange Nut (6151773) on

the back, inside the tub lip flange.

Tighten to 9Nm

Repeat on the opposite side using the opposite

hand front tub mounting bracket

Use from the kit M8 x 25 Torx head screw

(6151625) (use T40 bit) and M8 x 25.4mm flat

washers (4581303) in these 3 places.

Apply silicon to

tub joins in front

corners inside

and outside.

10-02-2020 Page 8 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

2.6) There are 2 alternatives to fixing the front tags of the

front tub mounting brackets to the front wall of the

tub:

Option A:

If a sports bar has been fitted, existing nutserts will

be mounted in the front wall of the tub.

For Option A:

Fit M8 x 25 Torx head screws (6151625) (use T40 bit)

and M8 x 25.4mm (4581303) flat washers. Do these

screws up to 18Nm

2.7) Option B:

If no nutsert exists, the front legs of the mounting

brackets are to be riveted to the front tub wall.

For Option B: Drill a 5.2mm hole through the hole

already provided in the brackets through the front tub

sheet metal wall using a drill stop set to 10mm deep.

Apply rust inhibitor to the holes.

Fit a pop rivet (6609087) to the hole in each front tub

bracket and secure them in place.

Repeat for the opposite side

10-02-2020 Page 9 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

2.8) Place 668PD046 front tub mount rail over the front

of the tub, foam tape and top lip of the bed liner (if

fitted). The “C” section shape of the bracket is to

point down and the small flange lip on the bracket is

to be orientated to the inside of the tub to retain the

top edge of any bed liner (if bed liner is fitted).

Align the front tub mount rail so the ends of it have

equal gaps to the vehicle’s side tub walls and inner

face is against the mating Front Mounting Brackets.

Then align the holes in the end of rails with the 2

holes in the in the tags of the front tub mounting

brackets.

!! IMPORTANT !!

Push down on the front mount rail at the ends so

that it is level to the top face of the vehicle’s side

tub walls while doing the screws up. A clamp can

be used to hold the front rail level with the top face

of the side tub walls.

2.9) Insert into the holes in the front corner brackets on

both sides an M6x20mm hex screw (6151213) with

M6 spring washer (4581287) and M6 x 25mm flat

washer (4584310) and do the screw up into weld

nut plate (668AQ010) on the inside of the front

mount rail to 9Nm.

When doing up the weld nut plate, hide

this leg behind the front mount rail.

Flange lip on

inside

Equal

gap on

both

ends

10-02-2020 Page 10 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

2.10) Apply to either end of the front mount rail a bridge

seal (668PM005), by removing the backing paper

off the adhesive side and sticking it down to the

dimensions shown opposite. The ramp profile

should go between the front header rail and the

side of the tub as a bridge.

!! IMPORTANT !!

POSITION THE SEAL BRIDGE EACTLY AS

SHOWN OR FRONT CORNER WATER LEAKS

COULD OCCUR

2.11) Apply silicon to the join areas underneath the

bridge seal to stop water leaks.

The bridge seal provides a transition from the

front tub mount rail to the top of the side tub walls

to provide a sealing surface to the seal that is

mounted on the underside of the canopy.

2.12) Prepare a pair of rear tub mounting bracket

(3759969R&L) with self-adhesive bumpons

(665076) applied in 5 places as shown. These

legs are to sit with the bumpons face down

touching the top edge of the vehicle’s tub once

the bracket is fitted

2.13) Apply Foam Pad 668PB023 to the rear of the

Rear Mounting Brackets as shown opposite by

aligning the foam pad with the edges of the

bracket

Repeat for the opposite hand

Align seal bridge front edge 5mm rearward from

the front edge of front mount rail and 20mm over

onto the side tub rail. Do this on both sides.

20mm

Aligned

10-02-2020 Page 11 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

2.14) Remove the existing screws from the rear top

corners of the tub. Place LH rear tub mounting

bracket (3759969L) over the holes.

IF FITTING BED LINER GO TO SECTION 7

Repeat on the opposite side using the

opposite hand tub mounting bracket

2.15) Drill the hole in the front of the bracket using a

6.5mm drill bit to a depth of 15mm using a drill

stop. Apply rust inhibitor to the hole.

Insert into the hole an M6 x 20mm Hex Screw

(6151213) with M6 x 25mm (4584310) Flat

Washer under the head and M6 Flange Nut

(6151173) on the back, inside the tub lip flange.

Tighten to 9Nm

If fitting a Bed Liner, place 6250026 behind the

bracket prior to fitting.

Repeat on the opposite side using the

opposite hand tub mounting bracket.

SECTION 3: FITTING THE SEALS

3.0) From the seal kit (6171422), clean the top of the

vehicle’s side tub rails down using alcohol wipes.

Apply the seal (9009177) in the orientation as

shown,

Starting at the rear and against the foam pad.

Use from the kit M8 x 25 Torx head screw (6151625)

(use T40 bit) and M8 x 25.4mm flat washers (4581303)

in these 2 places and tighten to 22Nm.

This side to the

outside of the vehicle

10-02-2020 Page 12 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

3.1) Align the seal along the sides of the tub. Ensure the

seal inner edge is aligned to touch the tags on the

rear corner brackets on the inner edge.

Apply the seal with firm pressure to the tub.

3.2) Around the front corners of the tub, apply the

primer stick (665044) to the front rubber bridges.

(Break the vial at the dots by squeezing and wet out

the felt tip to apply the primer). Allow the primer to

dry.

3.3) Apply the seal along to the front bracket at an even

offset to the inside of the tub. Ensure the seal inner

edge is aligned to touch the tags on the front corner

brackets on the inner edge.

Apply the seal with firm pressure to the tub.

10-02-2020 Page 13 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

3.4) Curve the seal without puckering around the

front corners and apply it no further forwards

than half the width of the rubber seal bridge.

Ensure the double-sided tape on the seal goes

up the ramp of the tub bridge and is not

stepped up across the corner of the tub bridge

which could cause water leaks. Apply firm

pressure to the seal over the tub bridge rubber

extrusion.

3.5) Apply the seal along the front head board bracket

aligned at 20mm offset between the inner edge

of the seal and the inner edge of the head

board rail. Apply the seal with firm pressure to

the tub.

3.6) Finish applying the seal to the other side of the tub.

3.7) Apply neutral cure silicon to edge of the bed seal

around the front corners both inside and outside of

the seal. Clean off excess with a rag applied

sparingly with silicon remover or wax and grease

remover carefully.

3.8) Apply neutral cure silicon to inside of each end of

the rail top corners. Clean off excess with a rag and

silicon remover or wax and grease remover

carefully.

20mm

10-02-2020 Page 14 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

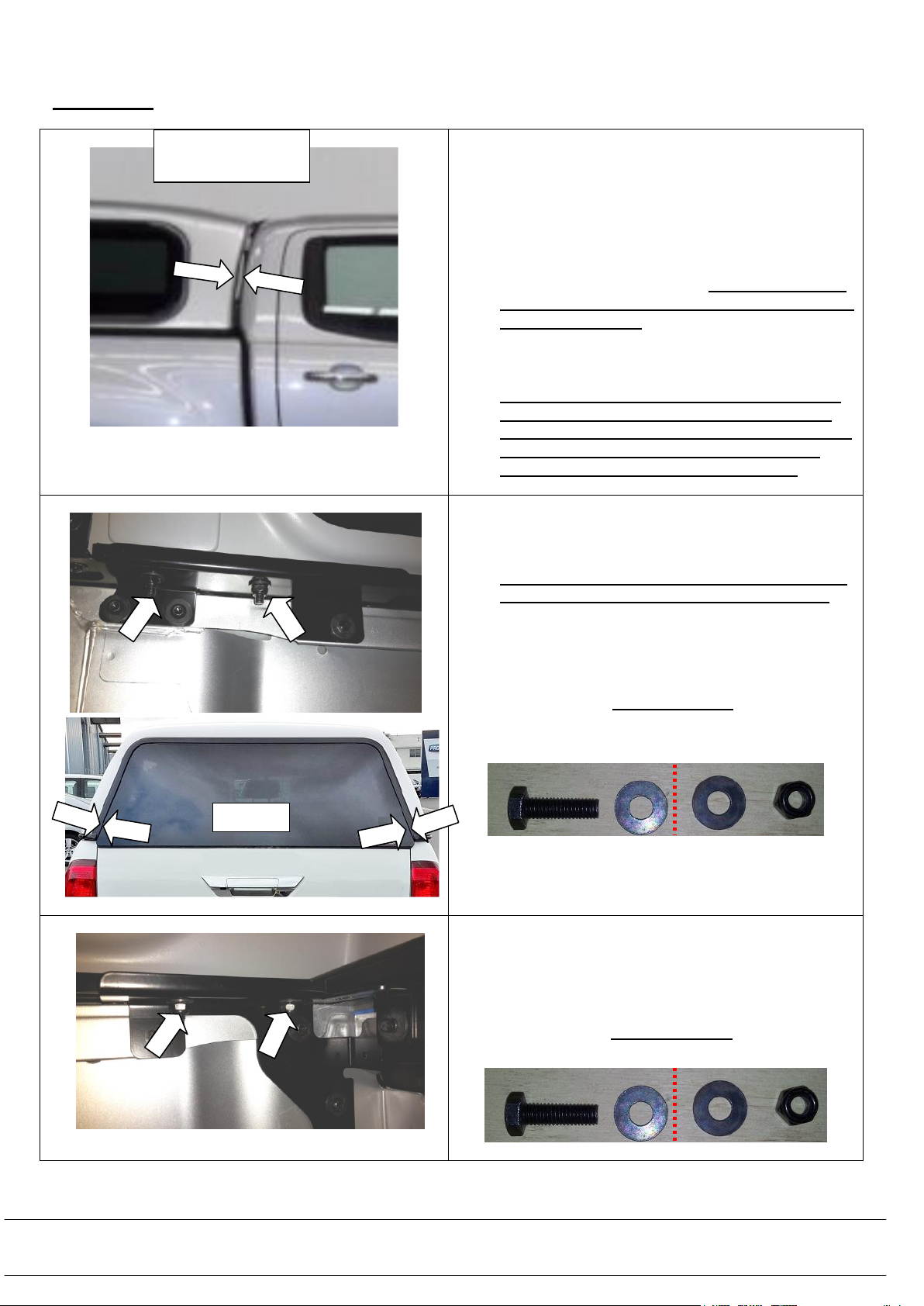

SECTION 4: FITTING THE CANOPY

4.0) Close the vehicle’s tailgate. Lift the canopy onto the

vehicle with 2 people. Avoid dragging the canopy

on the seals mounted on the tub as this could

dislodge them. Lift and place the canopy down

onto the vehicle’s tub. Open the door and tailgate.

The holes in the rear base rail corner inside,

should align to the centres of the slots on the

rear tub mounting brackets. Ensure the canopy

is evenly aligned on both sides to the tub and to

the vehicle’s cabin. Ensure pressure from the

door lower glass edge to the tailgate is not

excessive

There MUST BE 25mm or more clearance from

the canopy front pillars to the vehicle’s cabin

rear pillars. This is easily measured by inserting

a socket or round object with a 25mm outer

diameter between the canopy and cabin.

4.1) Align the holes in the base rail so the slots are

centred to the rear tub mounting brackets.

Ensure the gap between the door glass and the

door frame is even, and between 5 and 7mm.

Through the holes in the rear corner brackets fit

M8x25mm hex bolts (6151546) with M8x20mm

washers (4581307) down through the holes in the

top of the canopy’s base rail. Apply M8x20 washer

(4581307) and M8 nyloc nut (6151212) up from

underneath and tighten to 22Nm to the rear tub

mounting brackets.

4.2) Through the holes in the front corner brackets fit

M8x25mm hex bolts with M8x20mm washers down

through 6582445 Canopy Clamp making sure the

clamp is bearing down on the canopy base rails.

Apply M8x20 washer and nyloc nut up from

underneath and tighten to 22Nm.

5-7mm

25mm Minimum

Must not be less

10-02-2020 Page 15 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

4.3) Locate the hole in the centre of the base rail on the

inside of the canopy. Clamp bracket (3759852) to the

tub lip aligning the top hole in the base rail of the

canopy. Apply an M6x20mm hex bolt (6151213) with

M6x20mm (4581082) washer down through the hole in

the top of the base rail. and tighten to 9Nm.

Do this on both sides of the vehicle.

4.4) Drill a 6.5mm through the uppermost hole location in

the (3759852) brackets with a 12mm deep drill stop

fitted. Remove any swarf.

4.5) Apply rust inhibitor to the holes. Fit M6 x 20 mm hex

bolt (6151213), M6 x 25mm flat washer (4584310)

through the bracket and on the inside secure with M6

wizzlock (6151773) flange nuts. Tighten to 9Nm.

4.6) Cut the lower door gutter seals in line with the top of the

tailgate on both sides of the door so they just

touch the top of the vehicle’s tailgate

10-02-2020 Page 16 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

4.7) Cut the lower door sash seal attached to the glass on the

door at both ends to match the corners of the glass.

4.8) Fit both 3750205R&L rear corner brackets to bed rails

using M6 x 20 bolts, M6 x 20 washers and M6 flange

nuts.

Position in the corner close to but not touching the door

frame.

Do nuts up to 9Nm

4.9) With the tailgate down and door open, apply neutral cure

silicon up into the rear corner tailgate sealing

bracket areas, between the tub and the door frame and

canopy base rail and on the inside between the

bracket, door frame and shell to fully seal.

Clean up excess and smooth the silicon down on the

inside of the canopy.

10-02-2020 Page 17 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

4.10) Apply masking tape to the vehicle’s tailgate level with

the door’s lower glass edge.

4.11) Starting at the edge of the tailgate, roll out the clear

protection tape (665037) and start partially by removing

the tape backing liner as small section at a time.

4.12) Push out bubbles and wrinkles as the tape is being laid

down, working from one end of the tape with a

squeegee.

Trim the clear tape at the end level with the end of the

tailgate.

Remove the masking tape at completion.

10-02-2020 Page 18 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

SECTION 5: WIRING THE CANOPY

IMPORTANT

WIRING INSTALLATION IS DIFFERENT FOR GMH COLORADO AND ISUZU DMAX

Splicing into the rear taillights of a Colorado will cause the canopy brake light to run when the vehicles clearance lights

are activated.

THE FOLLOWING INSTRUCTIONS ARE DIVIDED INTO TWO SECTIONS FOR

COLORADO / ISUZU DMAX

IF FITTING THE CANOPY TO THE ISUZU DMAX; Go to page 21

COLORADO WIRING ONLY

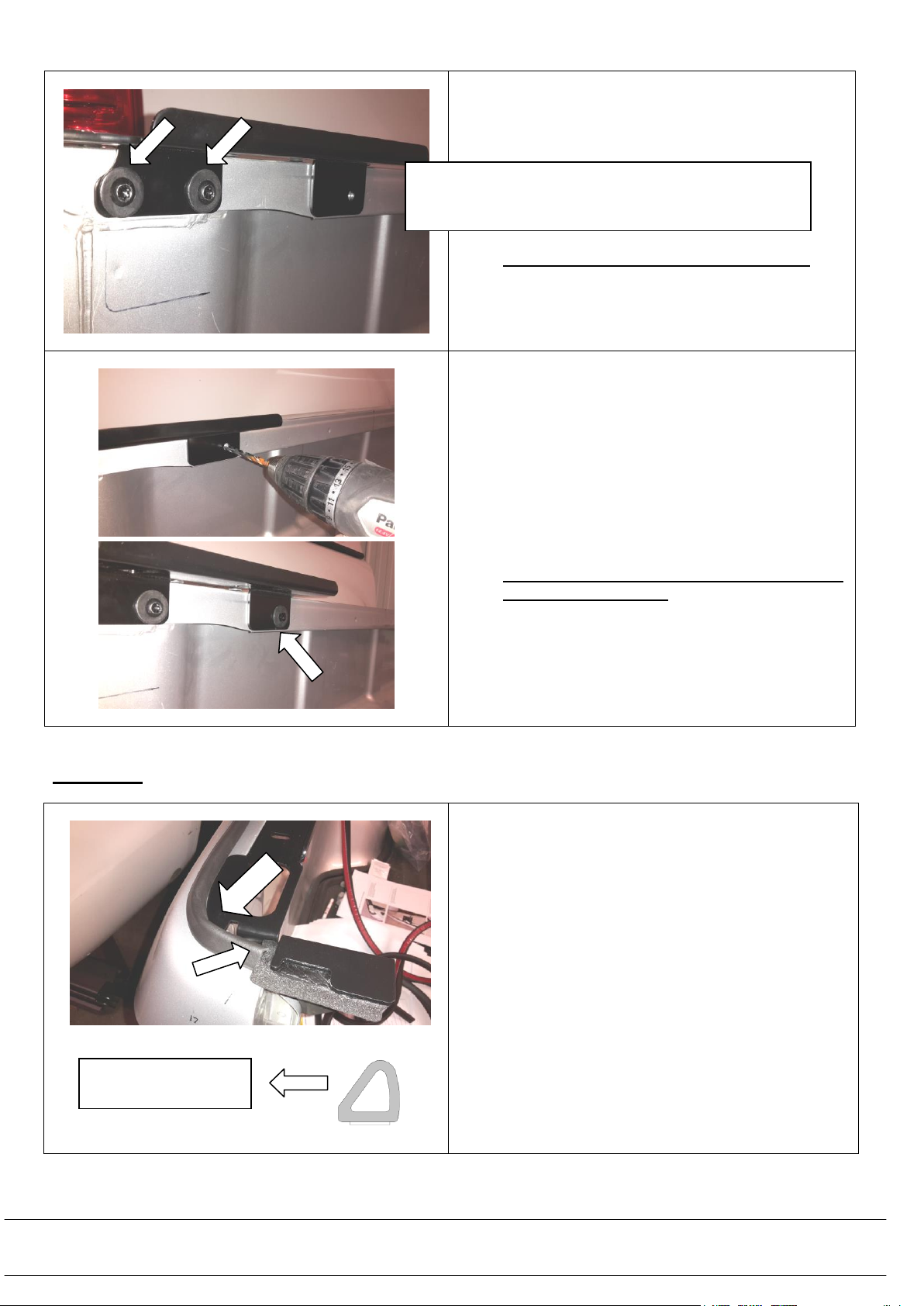

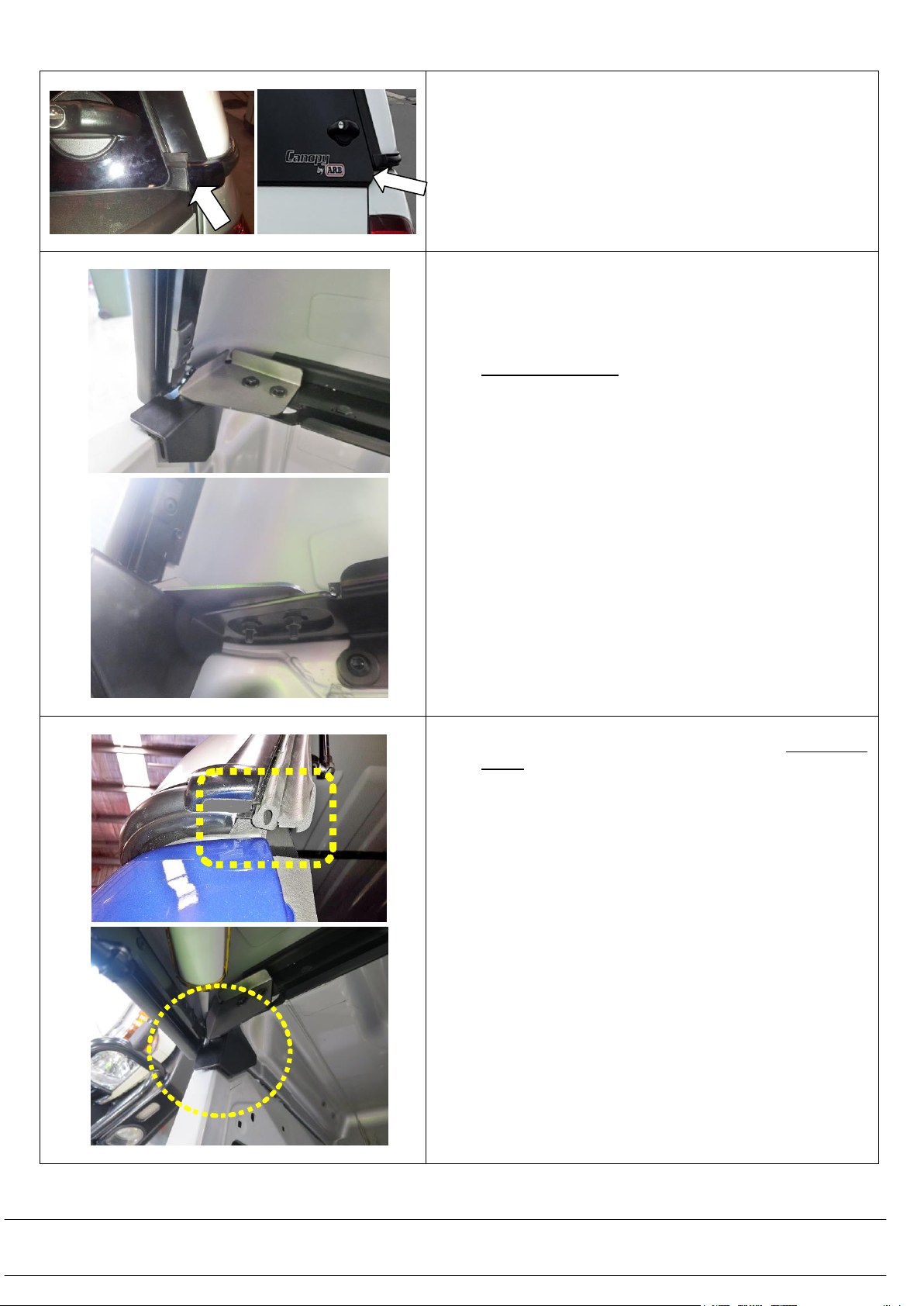

5.1) Go to the right-hand side rear door. Using panel

removal tools, carefully remove the bottom kick

panel and pinch weld seal. Using the removal tools

pry the rear corner cover piece away, exposing the

metal surfaces.

5.2) Locate the high mount stoplight power wire.

This should be PURPLE/WHITE. Double check all

wires, as to ensure the seat belt pre-tensioners or

interior light are not picked up.

10-02-2020 Page 19 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

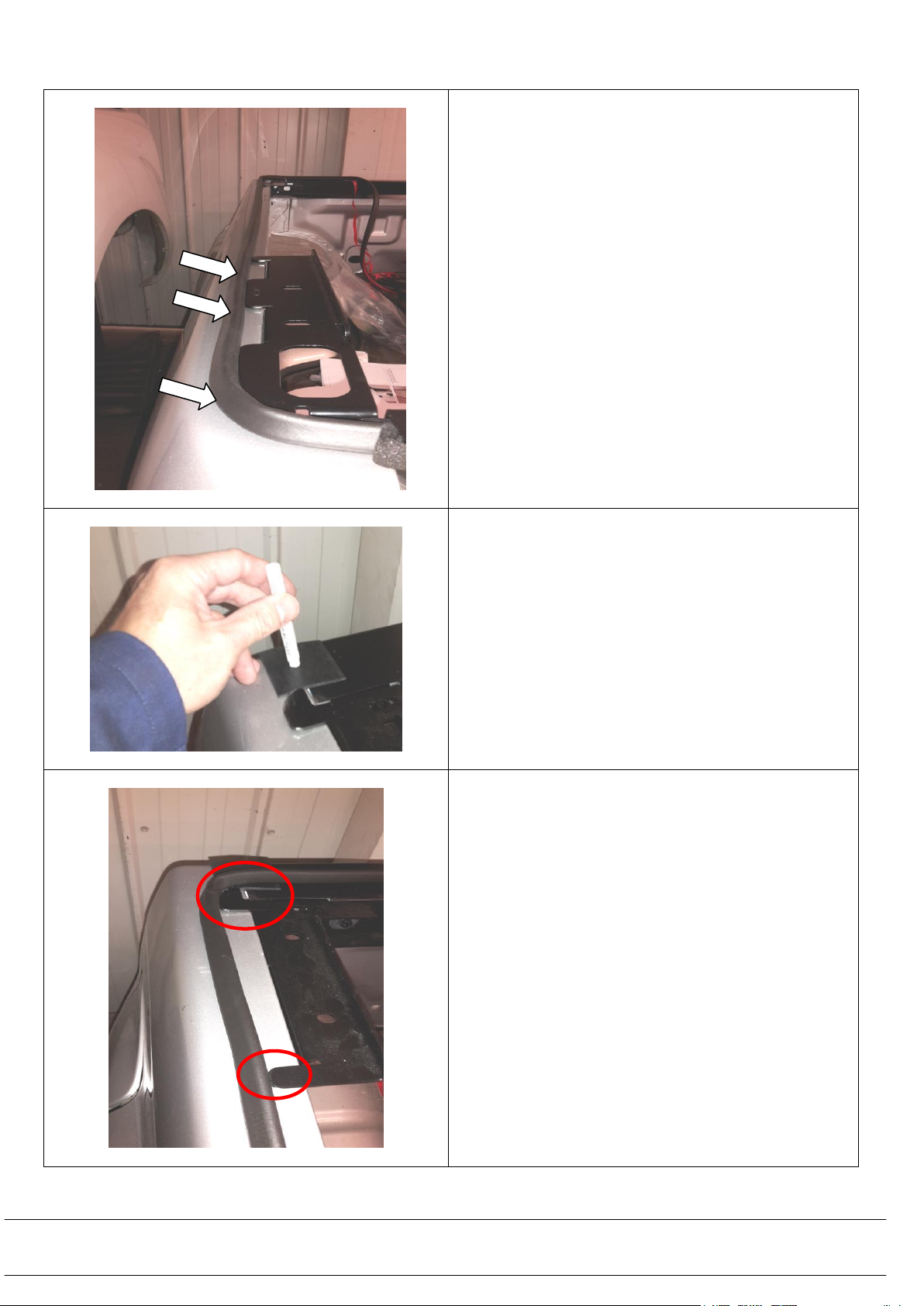

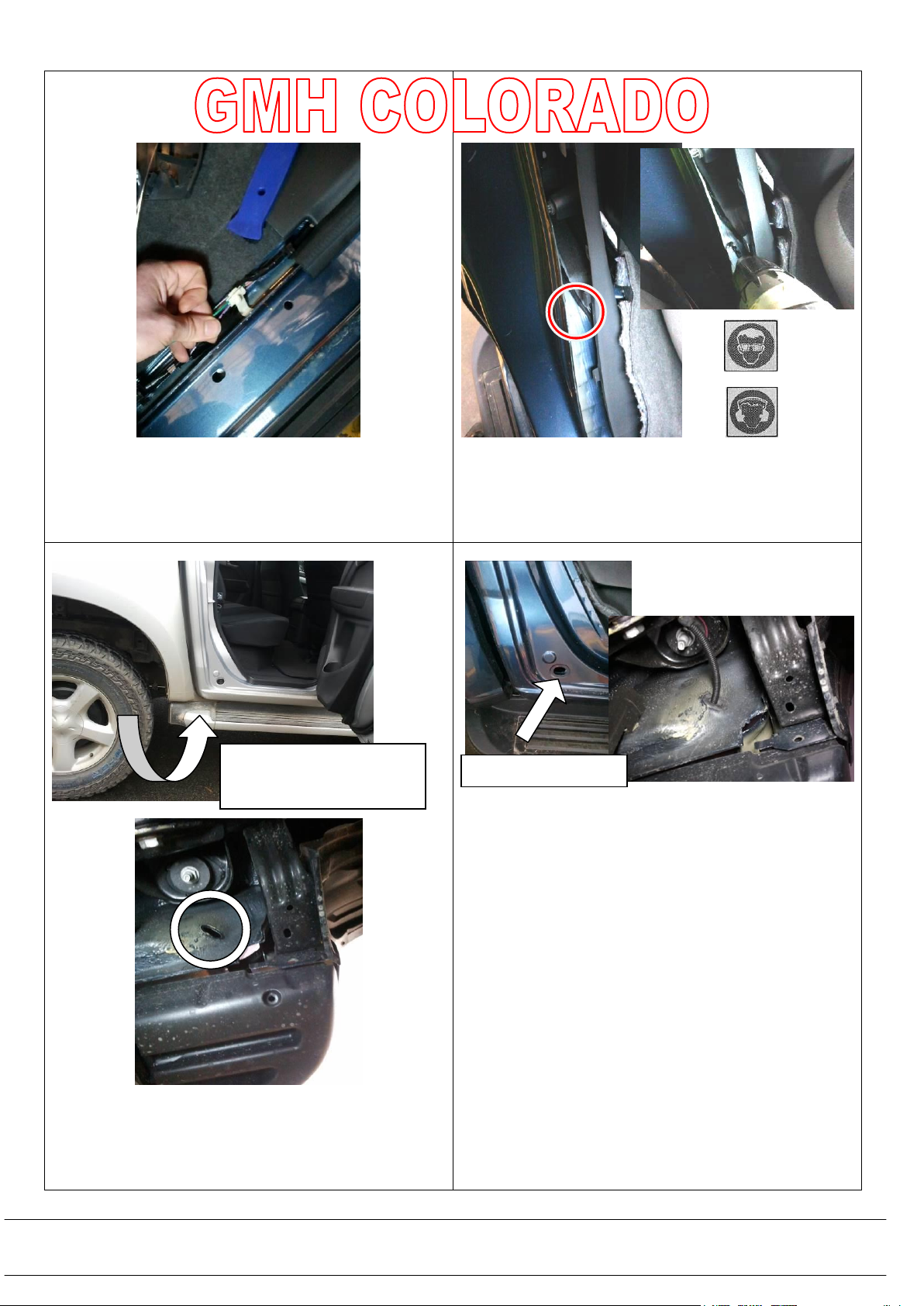

5.3) Scotch lock the loose 0.85mm red wire to the vehicle

brake wire. Cut the PURPLE/WHITE wire on the

brake side of the Scotch Lock to disconnect the high

mount stop light. Tape the scotch lock to avoid

rattles

5.4) Drill a 12 mm hole into the sheet metal into the

cavity in the lower rear corner as shown. Deburr the

hole, thoroughly clean away any swarf. Paint any

bare metal to prevent corrosion.

5.5) Using convoluted tube, and grommet. Feed the red

wire from the cabin into the rear corner cavity.

Feed the wire and tube out of the cavity through the

lower slot.

Cut the slot shaped grommet to fit over the

convoluted tube. Reinstall the slot shaped grommet

with convoluted tube.

Underneath the vehicle, locate and remove the slot

shaped grommet which leads into the rear corner cavity

where shown.

NOTE: A trace may aid installation through the

cavity. It is possible to “view” inside the cavity, by

removing the outer grommet shown in the picture

above.

VIEWING HOLE

EXISTING SLOT

UNDERNEATH VEHICLE

IN THIS SECTION

10-02-2020 Page 20 of 32 ARB Copyright 2017 3789736

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office –ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

5.6) Remove tail light assembly right hand side. Do this

by first undoing the 2 screws in the tailgate opening.

Then push the light backward

5.7) Drill 12mm hole through ute body / liner as shown.

Deburr and paint any bare metal, clean away any

swarf.

5.8) Run 2 Core Sheathed Wire (RED Positive BLACK

Negative) and Stop Light (BLACK WHITE Positive)

from the door frame through 250mm length of

conduit in behind rear taillight.

Fit grommet to hole in body.

Fit the conduit to the doorframe and through the ute

body / liner.

5.9) Continue feeding convoluted tube with dual core wire

down the chassis rail to the red wire exiting the

cabin, avoiding any sharp hot or moving objects.DO

NOT CABLE TIE THE CONVOLUTED TUBE YET.

Feed the loose red wire through the convoluted tube

back up into the tail light cavity. Scotch lock the

LOOSE RED wire to the canopy brake light wire

(BLACK/WHITE).

Test the brake light to ensure it works.

This manual suits for next models

2

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB RD166 User manual

ARB

ARB AIRLOCKER RD168 User manual

ARB

ARB 3432300 User manual

ARB

ARB Flinders User manual

ARB

ARB Airlocker RD143 User manual

ARB

ARB Air Locker RD204 User manual

ARB

ARB 3921120 User manual

ARB

ARB AIRLOCKER RD128 User manual

ARB

ARB AIRLOCKER RD216 User manual

ARB

ARB AIRLOCKER RD153 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction