ARB AIRLOCKER RD196 User manual

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB Airlocker RD232 User manual

ARB

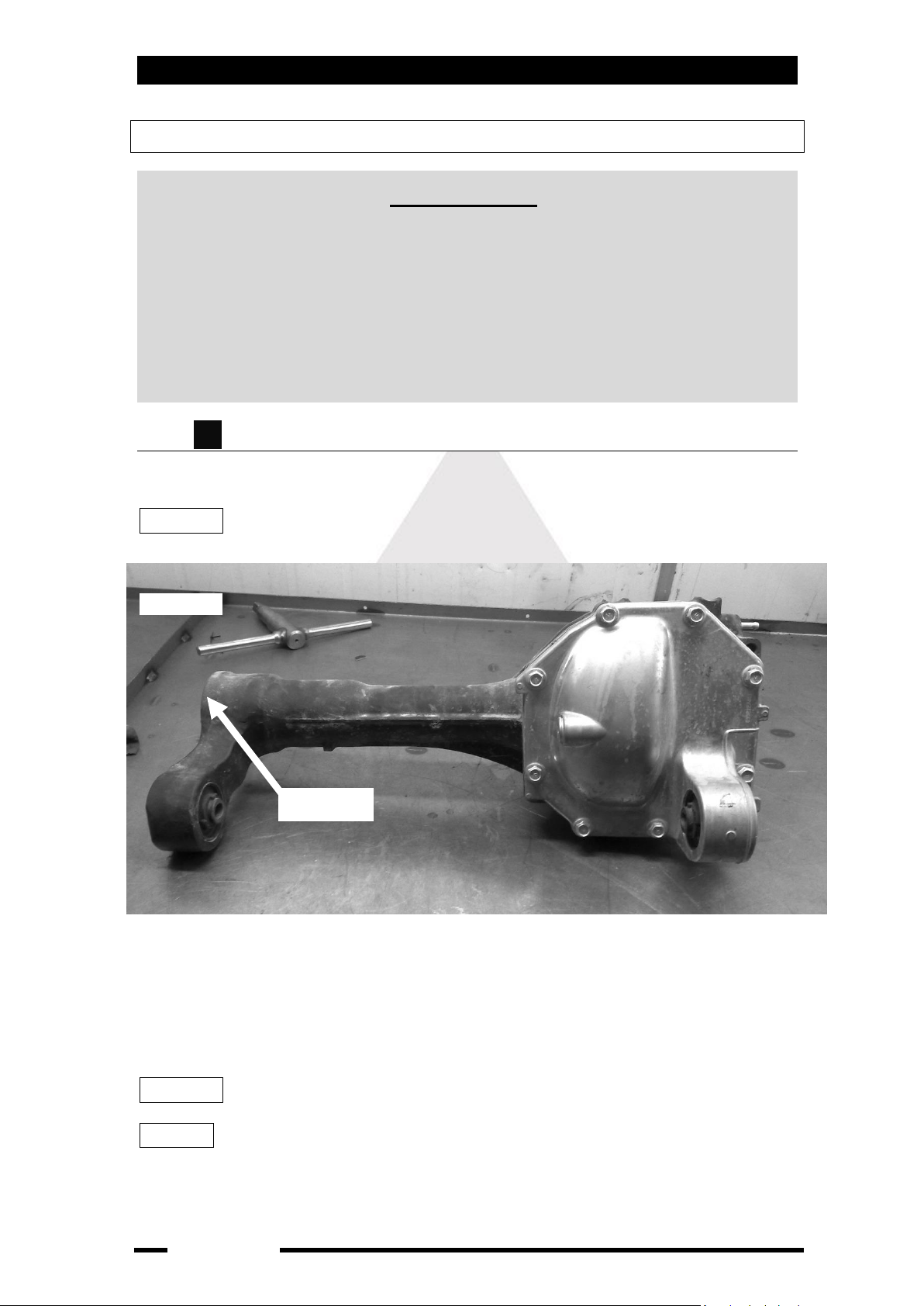

ARB Airlocker RD143 User manual

ARB

ARB 3940420 User manual

ARB

ARB LINX LX100 User manual

ARB

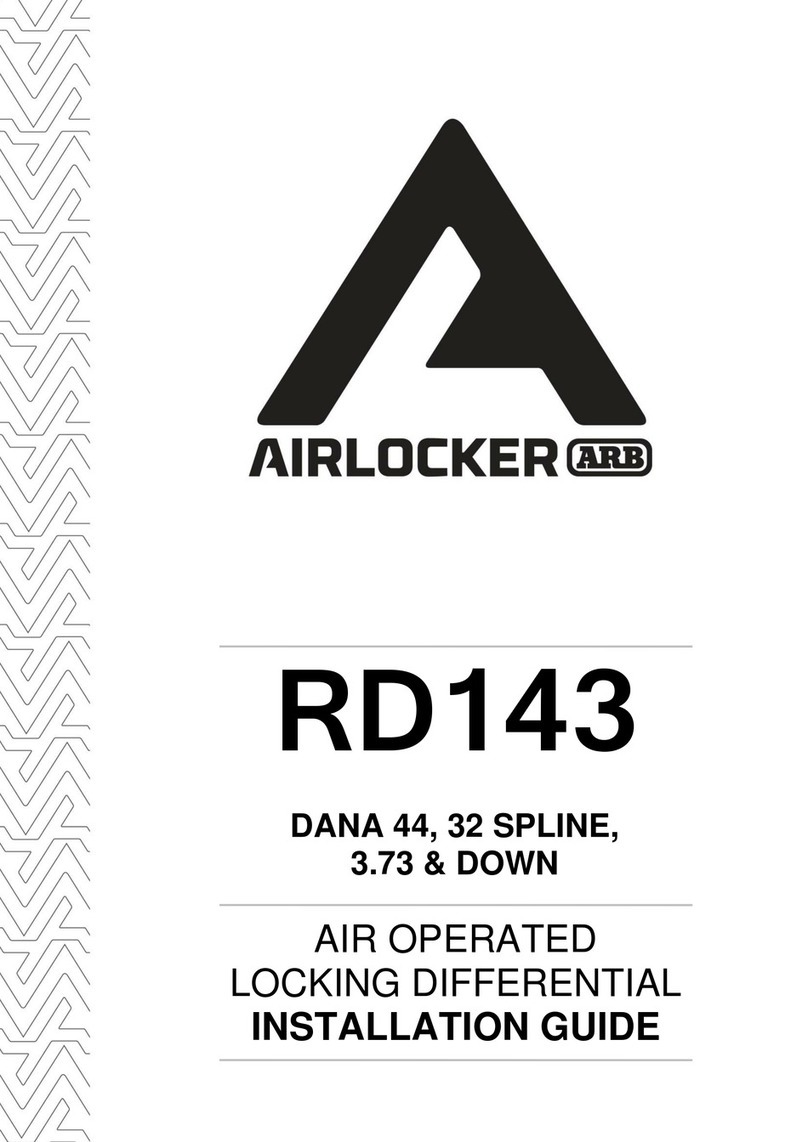

ARB AIRLOCKER RD128 User manual

ARB

ARB RD177 User manual

ARB

ARB AIRLOCKER RD153 User manual

ARB

ARB 3921120 User manual

ARB

ARB AIRLOCKER RD109 User manual

ARB

ARB Airlocker RD259 User manual

ARB

ARB INTENSITY IQ User manual

ARB

ARB 341 4460 User manual

ARB

ARB INTENSITY SOLIS User manual

ARB

ARB Airlocker RD161 User manual

ARB

ARB RD246 Product information sheet

ARB

ARB 341 4480 User manual

ARB

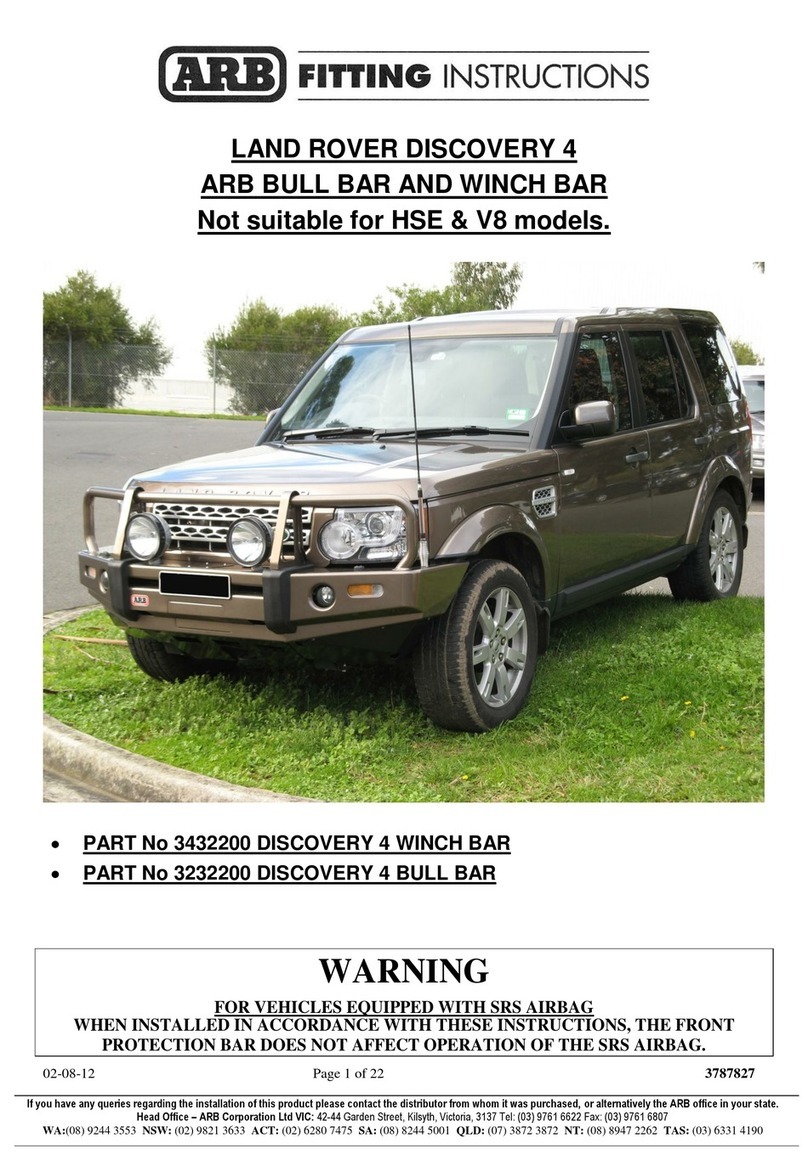

ARB 3432050 User manual

ARB

ARB AIRLOCKER RD163 User manual

ARB

ARB AIRLOCKER RD145 User manual

ARB

ARB AIRLOCKER RD170 User manual

Popular Automobile Accessories manuals by other brands

A&E Systems

A&E Systems 8300 operating instructions

Iron Cross

Iron Cross GP-2000 installation instructions

F.lli Menabo

F.lli Menabo ACONCAGUA 3.0 Fitting instructions

Griffin Technology

Griffin Technology iTripAutoPilot user guide

Hama

Hama 00 123530 operating instructions

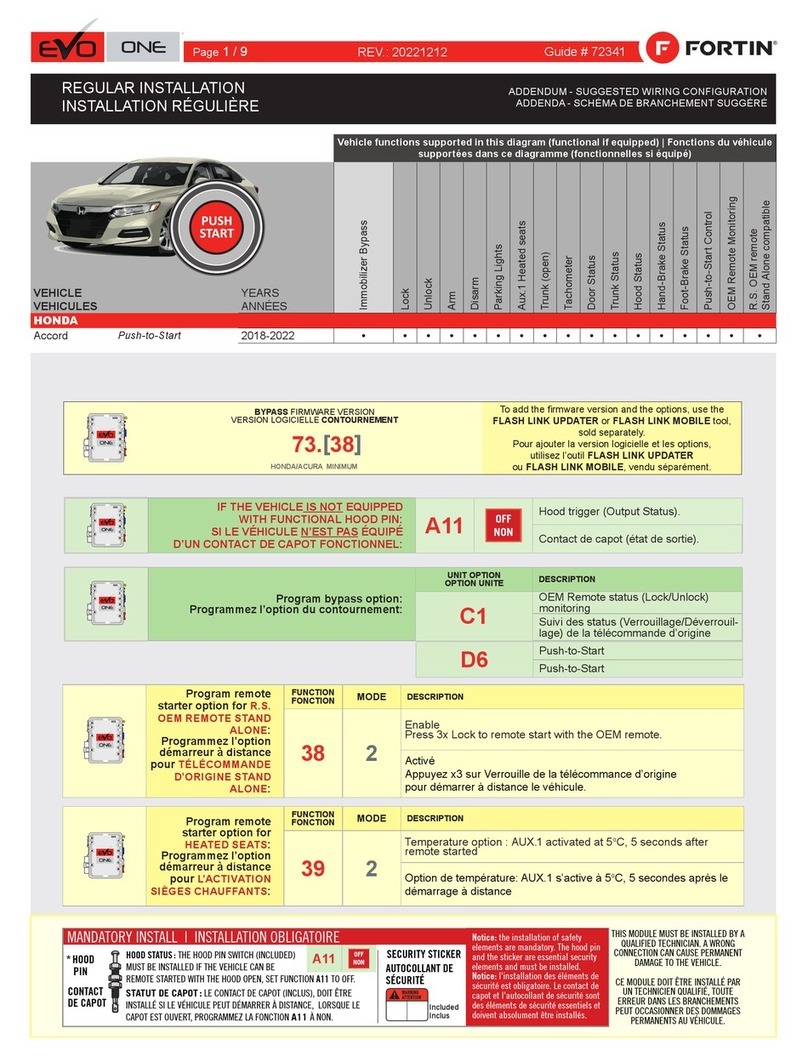

Fortin

Fortin EVO ONE installation guide