ARB RD121 Operating and maintenance instructions

Table of contents

Other ARB Automobile Accessories manuals

ARB

ARB Airlocker RD149 User manual

ARB

ARB RD116 User manual

ARB

ARB Air Locker RD204 User manual

ARB

ARB LINX LX100 User manual

ARB

ARB AIRLOCKER RD109 User manual

ARB

ARB 3414470 User manual

ARB

ARB AIRLOCKER RD208 User manual

ARB

ARB 3424010 User manual

ARB

ARB AIRLOCKER RD216 User manual

ARB

ARB 3444070 User manual

ARB

ARB Airlocker RD232 User manual

ARB

ARB Airlocker RD214 User manual

ARB

ARB Airlocker RD140 User manual

ARB

ARB 17940080 User manual

ARB

ARB AIRLOCKER RD170 User manual

ARB

ARB 2237010 User manual

ARB

ARB AIRLOCKER RD128 User manual

ARB

ARB AIRLOCKER RD168 User manual

ARB

ARB 3917140 User manual

ARB

ARB Airlocker RD152 User manual

Popular Automobile Accessories manuals by other brands

Whispbar

Whispbar K392W Fitting Instructions for Basic Carrier

NavLinkz

NavLinkz RL4-UCON8-LV manual

Brink

Brink 4926 Fitting instructions

Fiamma

Fiamma 08753-01 Installation and usage instructions

ClimAir

ClimAir Sonniboy installation instructions

Roadmaster

Roadmaster Falcon 2 Owner's Manual & Installation Instructions

Escort

Escort SmartCord Live user guide

SAN HIMA

SAN HIMA SH-TENT-SY20 user manual

Paxton Automotive

Paxton Automotive 1300001 installation manual

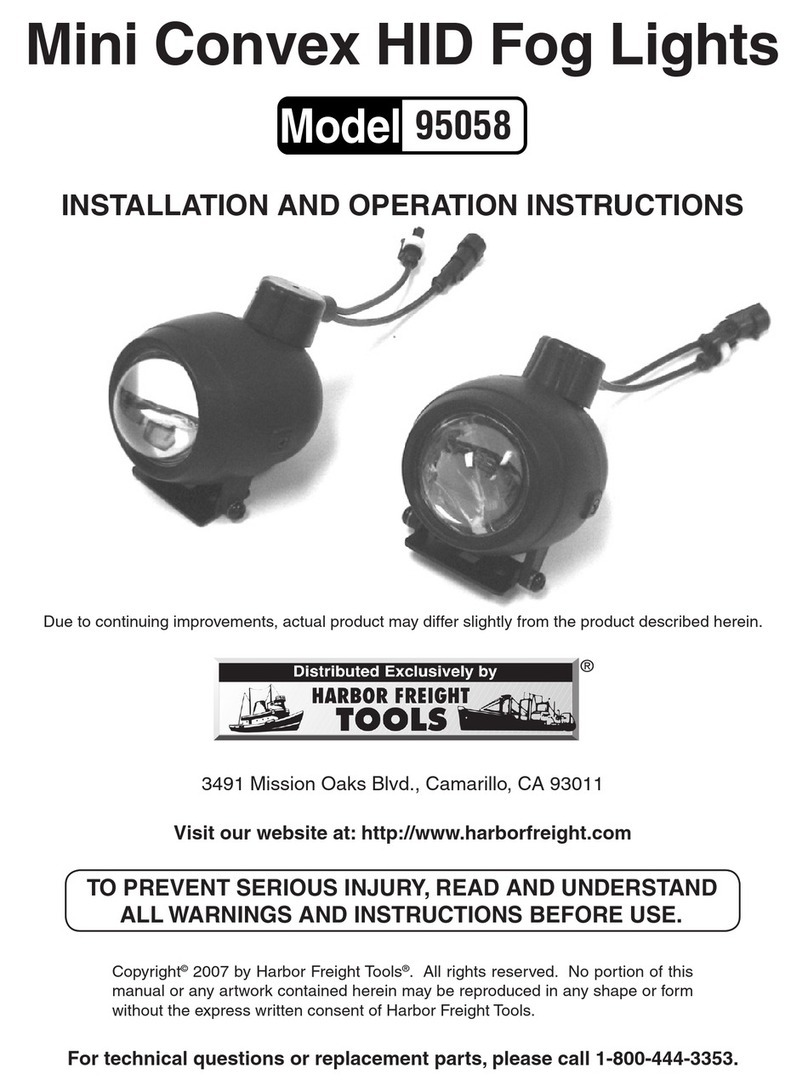

Harbor Freight Tools

Harbor Freight Tools 95058 Installation and operation instructions

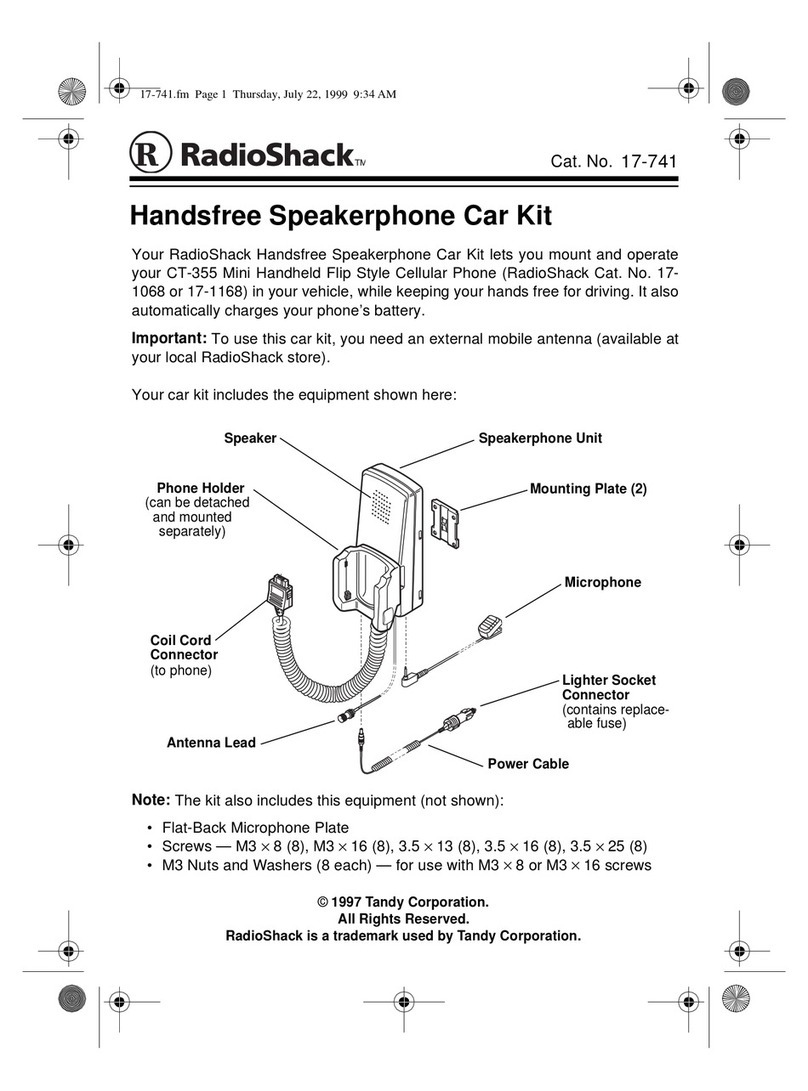

Radio Shack

Radio Shack 17-741 user manual

Motec

Motec MVCD1000-x installation instructions