- 1-

Preparations for Use

FI TERS:

Before you begin welding always inspect your filter to ensure it is not damaged. Check to

see if the filter protection plates (cover plates) are clean, clear, undamaged, and securely

attached to the helmet and covering the auto-darkening filter both front and rear.

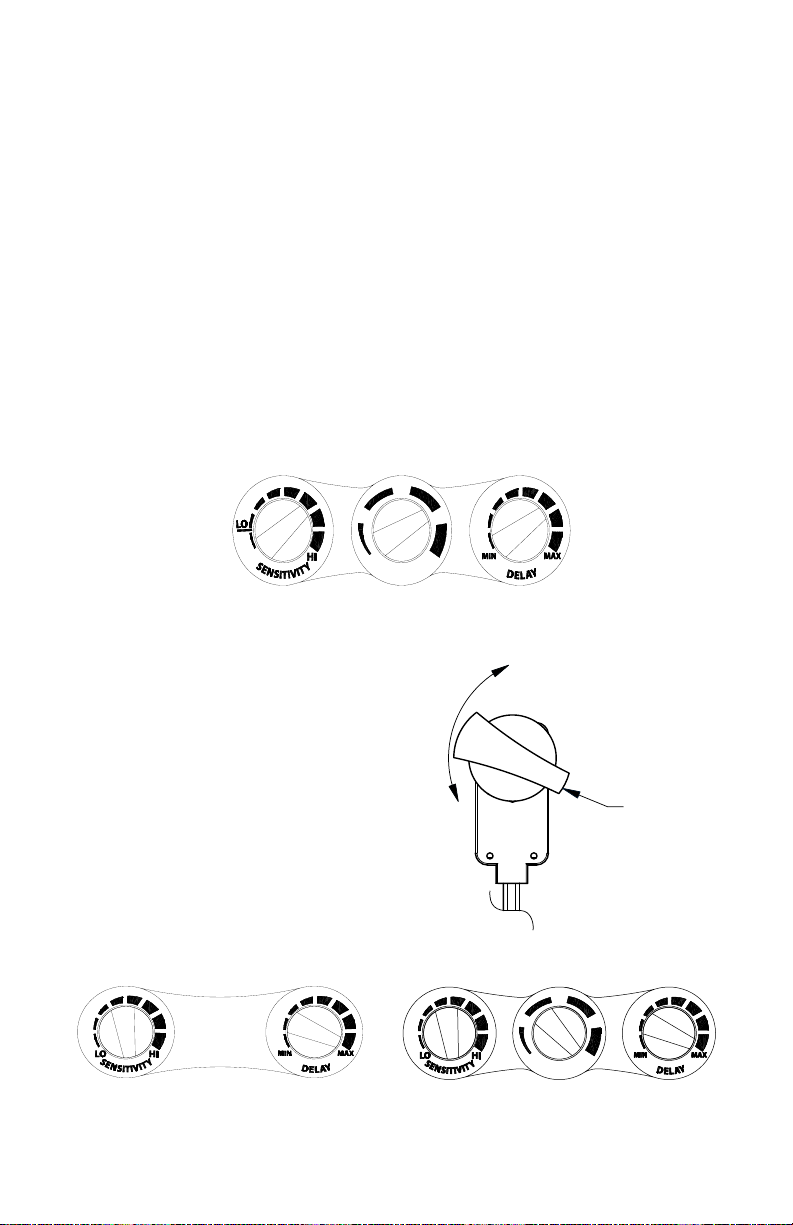

To test your filter, prior to welding, direct the front of the filter to a bright source of light

then, using your fingers, rapidly cover and uncover the sensors. The filter will darken

momentarily. Another means of testing is to utilize a torch striker or TV or VCR remote.

These devices will also momentarily darken the filter. Once you are sure that the filter is

working properly you are now ready to begin welding.

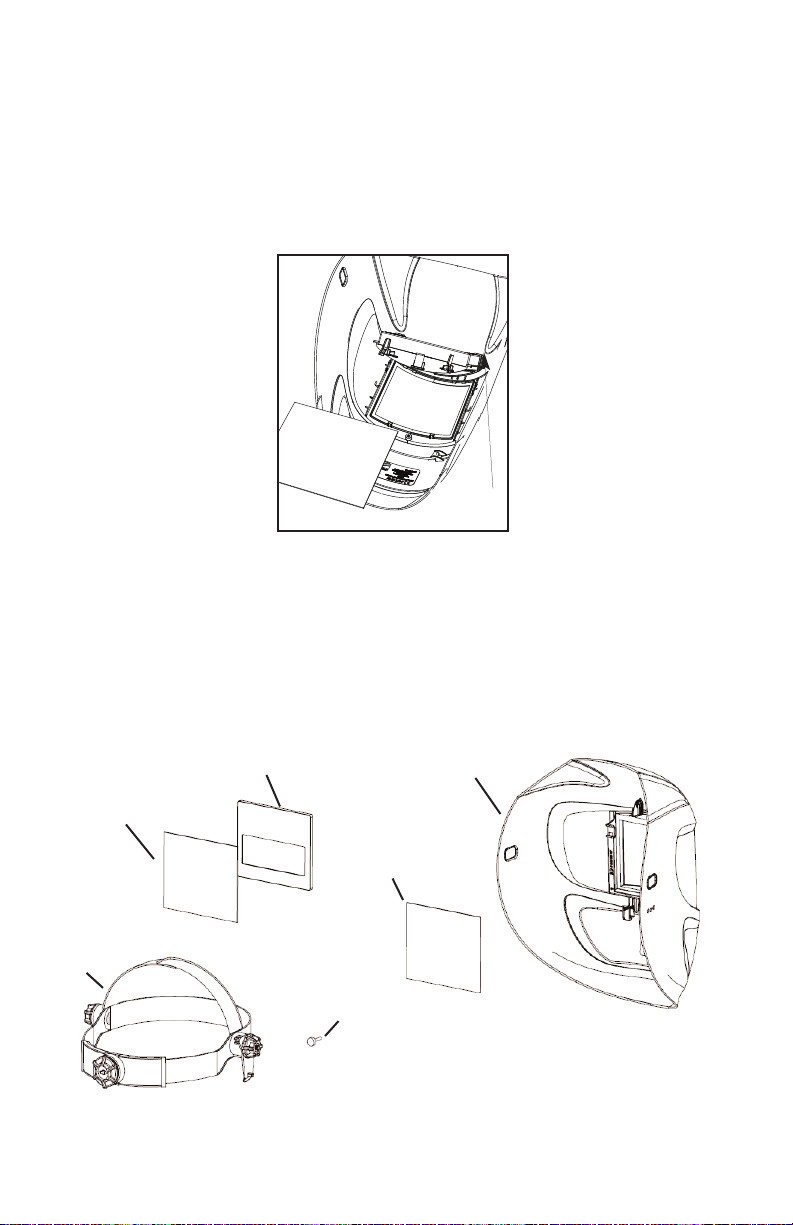

WARNING, Never begin welding without first checking to see if the correct front

protection plate is in place (see Part Selection Guide section for part numbers),

the filter is secured properly in the filter holder, and the filter holder secured in the

helmet . Failure to protect the welding filter or install the filter/filter holder

correctly may cause damage and become a safety hazard should the UV/IR

protection be compromised from spatter or cracks from impact. DAMAGE

CAUSED BY ABUSE SUCH AS EXCESSIVE TEMPERATURES, CRACKS FROM

IMPACT, AND PITTING FROM SPATTER CAUSED BY POOR MAINTENANCE WI

VOID WARRANTY.

WE DING HE METS:

Before you begin welding make sure there is no damage to the helmet shell including, but

not limited to cracks, holes, and melting. Ensure that the springs holding the filter are not

broken or corroded. Do not use the helmet if any of these conditions exist and contact your

distributor for replacement parts.

WARNING, Secondary impact protection required. Other safety precautions such

as protective clothing, adequate ventilation, breathing protection, fire

extinguisher, and protection for co-workers, should also be considered.

Not for use in overhead welding.

WARNING, Materials which may come into

contact with the wearer’s skin could cause

allergic reactions to susceptible individuals.

HEADGEAR:

Adjust the crown height via the pin hole adjustment

on the top strap of the headgear (see Figure1).

Adjust the circumference by turning the rear

knob while wearing.

Figure 1

Helmet Angle

Adjuster

TAB E OF CONTENTS PAGE

Preparations for Use 1

Technical Information/Use 2

Limitations of Use 3

Care and Maintenance 3

Spatter Protection 4

Parts Selection Guide 4

Filter Removal Instructions 5

Significance of Markings 5

Filter Specifications 6

Warranty and Service Information 7

Pin Hole

Adjustment

Adjust Fit: Push In, Turn, Release

Adjust Height: Snap

Out, Slide, Snap In