Filter Removal Instructions

Warrant and Service Information

Limited Warranty

85 Independence Drive, Taunton, MA 02780

(800) 223-4685

Arc ne®

warrants all auto-darkening filters covered by this manual for two (2) years from the date of pur-

chase against manufacturing defects resulting from materials or workmanship. Proof of purchase estab-

lishing the date of sale and filter serial number must be provided, should a warranty claim be

submitted. The purchaser’s only remedy under this limited warranty shall be limited to

Arc ne’s

sole op-

tion to repair, replace or refund (not to exceed the purchase price). This limited warranty is void in the case

of unauthorized modification, tampering, and damage due to misuse, abuse, inadequate maintenance or

improper storage. This limited warranty is not transferable from the original purchaser to a secondary owner.

Arc ne®

shall in no event be liable or responsible for any injury, damage or loss

resulting either directly or indirectly from the use or misuse of this product. This limited warranty is

exclusive and is in lieu of any other warranty implied either oral or written. Please read the instruction man-

ual carefully to avoid certain situations which may void this limited warranty.

Troubleshooting or Return Authorization, call (800) 223-4685 or visit www.arc1weld-

safe.com

Figure 7

USER INSTRUCTION MANUAL

CARRERA HELMET WITH

AUTO-DARKENING FILTER

Preparations for Use

Filters:

Before you begin welding always inspect your filter to ensure it is not damaged.

WARNING, never begin welding without first checking to see if the correct front

protection plate is in place, the filter is secured properly in the filter holder, and the

filter holder secured in the helmet. Failure to protect the welding filter or install the

filter / filter holder correctly may cause damage and become a safety hazard should

the UV/IR protection be compromised from spatter or cracks from impact. DAMAGE

CAUSED BY ABUSE SUCH AS EXCESSIVE TEMPERATURES, CRACKS FR M IMPACT,

AND PITTING FR M SPATTER CAUSED BY P R MAINTENANCE WILL V ID WARRANTY.

Welding Helmets:

WARNING, other safety precautions such as protective clothing, adequate ventilation,

breathing protection, such as a Clean Air FlowTM or equal, fire extinguisher, and

protection for co-workers, should also be considered.

Technical Information / Use

Filters:

Warning: Severe burns are possible with a

damaged lens (cracks, pits, holes, etc.).

Do not use damaged lens. ptical radiation

can possibly enter in from behind the

helmet from other welders welding in the

immediate area.

Filter Specific Features

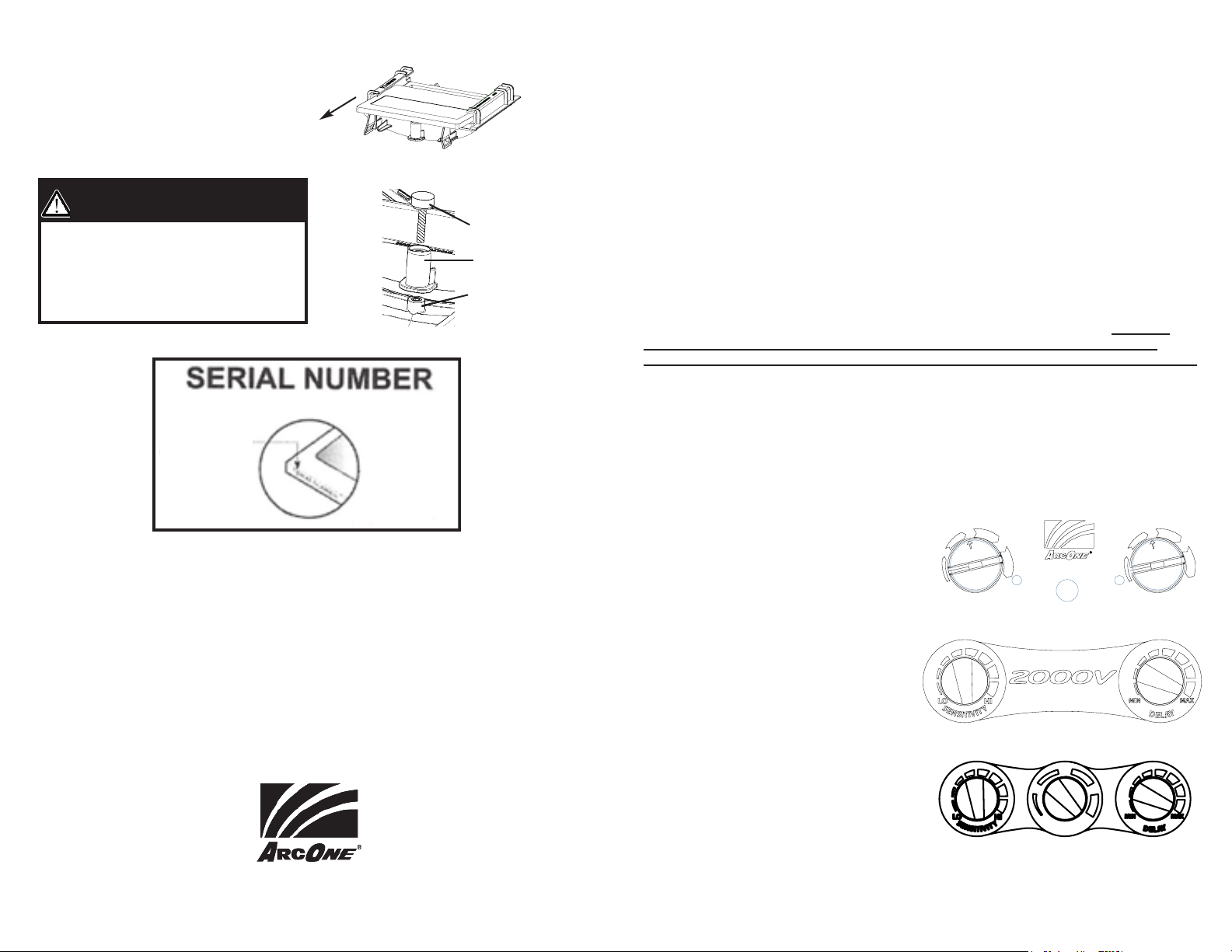

1000FcF ( ee Figure 1): hade and ensitivity are

adjusted using the knobs on the back of the filter.

Change the Delay by quickly pressing and releas-

ing the Delay/Grind button. The red delay LED will

turn on for Delay. Press and release the

Delay/Grind button again to turn off. To activate

the grind mode, press and hold down the

Delay/Grind button until the red Grind LED turns

on. Deactivate Grind mode by quickly pressing

and releasing the Delay/Grind button again. Grind

LED turns off.

2000V: hade knob is on the outside of the hel-

met. ensitivity and Delay are adjusted using the

knobs on the back of the filter ( ee Figure 2). This model does not have Grind mode.

2500V: ame as 2000V with the addition of shade to the back. ( ee Figure 3)

D E L A Y / G R I N D

L O H I

99

1100

1111

1122

1133

1000

S E N S I T I V I T Y S H A D E

G R I N D D E L A Y

FFccFF

Figure 1

CARRERA-02-UI REV C

Thumb crew

Filter Holder Boss

Centering Pin with

Threaded Insert

Figure 6

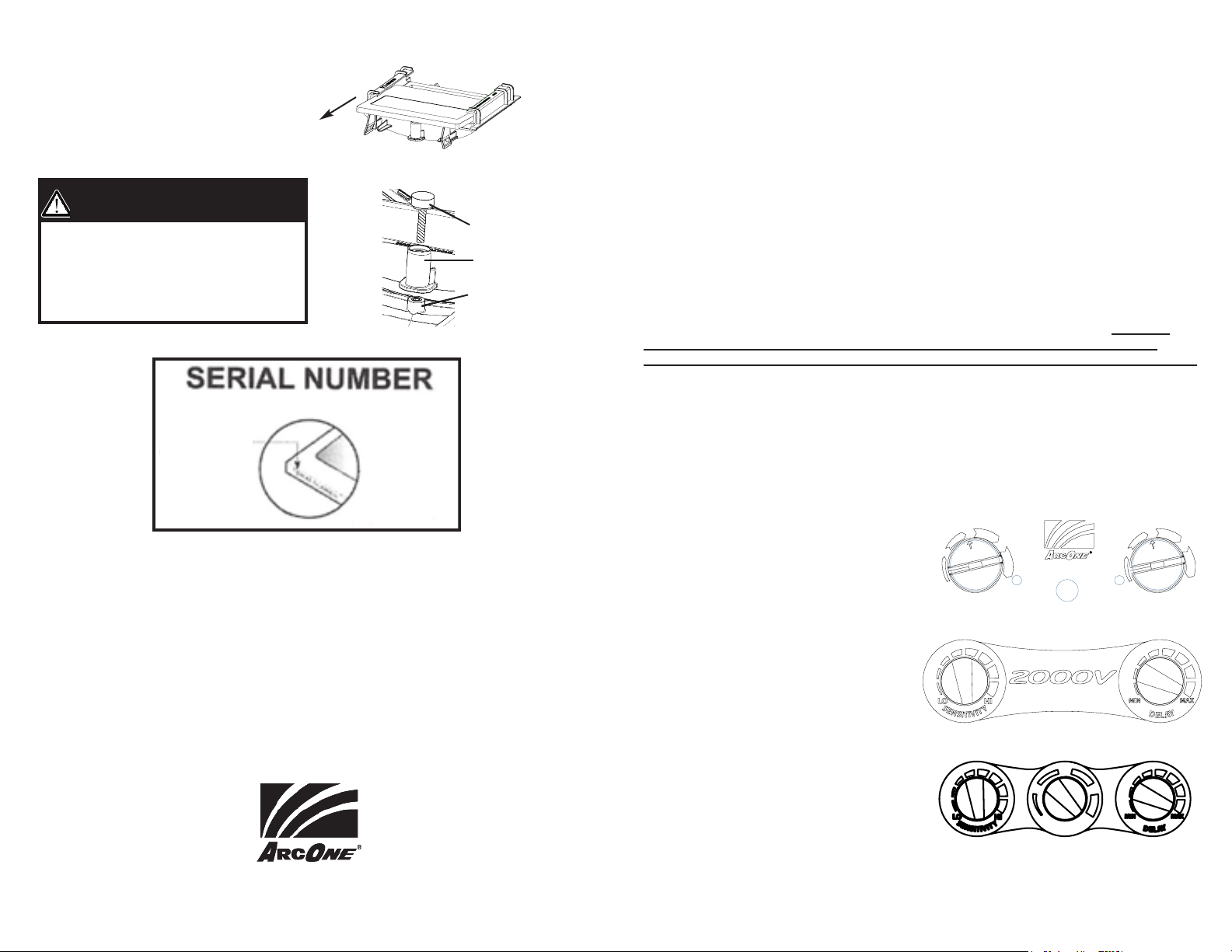

Removable Filter Holder

1. Grab filter by top and bottom edge

2. Pull up on bottom edge of filter and slide out

of the bottom of the filter holder (Fig. 6)

Critical Installation Warning!

Helmet impact rating Z87+ with Thumb

crew installed. Helmet rating Z87 without

thumb screw. For Z87+ make sure Filter

Holder Center Tab is secured to the Welding

Helmet Centering Pin with Thumb crew ( ee

Figure 7). Do not over tighten

Figure 2

Slide

Located along filter

edge or back

Figure 3

Printing:

1. Rotate Page 2

2. Print as 2-sided Letter, black

and white