Delay Adjustment and Grind Mode (not on all Models)

Digital Controlled Filters: Briefly press the “Mode” button (see Figure 1), the LCD mode will

flash to indicate the current setting (see Figure 3). Press and hold the “+” or “-” button to change

the setting. OTE: Some models have a dedicated Delay button with the “+” or “-” to change the

setting.

Analog Controlled Filters: Feature is not available on all analog models. Refer to Table 1: Filter

Specifications.

1000FCF: Turn Sensitivity knob counter-clockwise past the white line to lock into rind Mode.

4000V: Turn Shade knob counter-clockwise past shade 9 to enter rind Mode.

4500V: Set switch located on back of filter in the down position labeled “ RIND.” Set to “WELD”

before any welding application.

6000VI4: Press the “Delay” button on the back of the control center to turn delay on or off.

Intelligent Darkening Filter (IDF) Modes

The iDF48 in the USA has both Auto-Variable and iTI Mode; models outside the USA have only

Auto-Variable Mode. To switch from one mode to another Press AND Hold down the “Mode”

button for two seconds. To cycle through modes continue depressing the “Mode” button.

(***NOTE: Modes will not switch when in rind Mode.)

Auto-Variable Mode: LCD displays “AUTO” (see Figure 3c). Press, but do not hold, the “Mode”

button to select between shades 5-8 or shades 9-13. Filter automatically responds to the

intensity of the welding arc and sets the filter to the appropriate dark shade. The Auto-Variable

mode is dependent upon light intensity of the arc and distance from the filter to the arc. The user

can further adjust the dark shade up or down one shade number for comfort while the word

“AUTO” is flashing. This mode has one memory position for each shade in the dark state; i.e. 9,

10, 11, 12, and 13. (NOTE: Shade 13 cannot be set higher than 13. This Mode only works on

split range; i.e. 5-8/9-13 filters in the higher shade range). To reset all memory slots press and

hold both “Mode” and “Delay” buttons for two (2) seconds.

iTIG Mode: Upon entering iTI mode, where LCD displays “TI ” icon and flashing “(٠)” (see

Figure 4) user first sets lower desired shade while the “(٠)” flashes. After approximately five (5)

seconds of not turning the shade knob the flashing stops and the user can then set the desired

upper shade. The lowest possible shade is fixed according to the standard to which the filter has

been tested (example: iDF48, iTI in 9-13 range shade 9 lowest and shade 13 highest, in 5-9

range shade 7 lowest and shade 9 highest.)

Limitations of Use

Filters:

ArcOne®welding filters are not designed for oxy-acetylene, laser, or very low amperage welding

applications. Arc detection may be impaired due to amperage, distance from the arc, welding

current frequency, electrode type, shielding gasses, and lighting conditions.

DO OT weld with filter in the light state. If the filter fails to turn dark immediately stop use and

contact a service provider for help.

Welding Helmets:

Welding helmets are designed to provide protection against UV/IR radiation around the user's

face. ArcOne® welding helmets meet/exceed face coverage defined by CE standards. ArcOne®

welding helmets are suitable for arc welding. Refer to any or all of the following standards for

more specifications: ANSI Z87, CAN/CSA Z94.3, and CE EN 166 & 175.

CAUTION: not meant to protect against Severe Impact, explosives, fragments from grinding

wheels, abrasive discs, and hazardous fluids. Use secondary impact protection, such as safety

glasses.

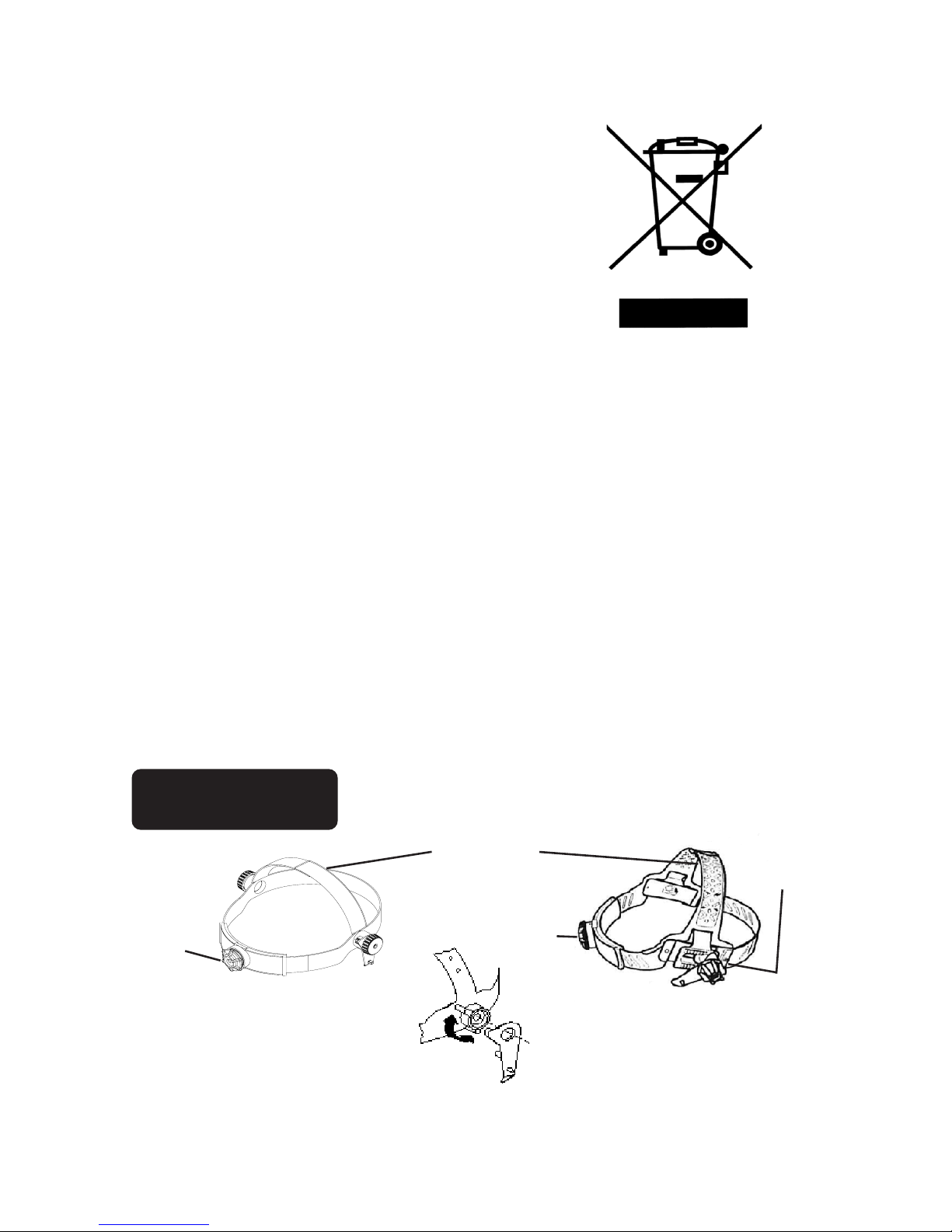

Figure 3a: LCD Readout

(5000V, 5500V, 5130V, 7000V,

and 7500V)

Figure 3c: LCD Readout

(iDF48)

- 3-

X-TIG

Figure 3b: LCD Readout

(5000VX, 5500VX, 5130VX,

7000VX, and 7500VX)