- 5 -

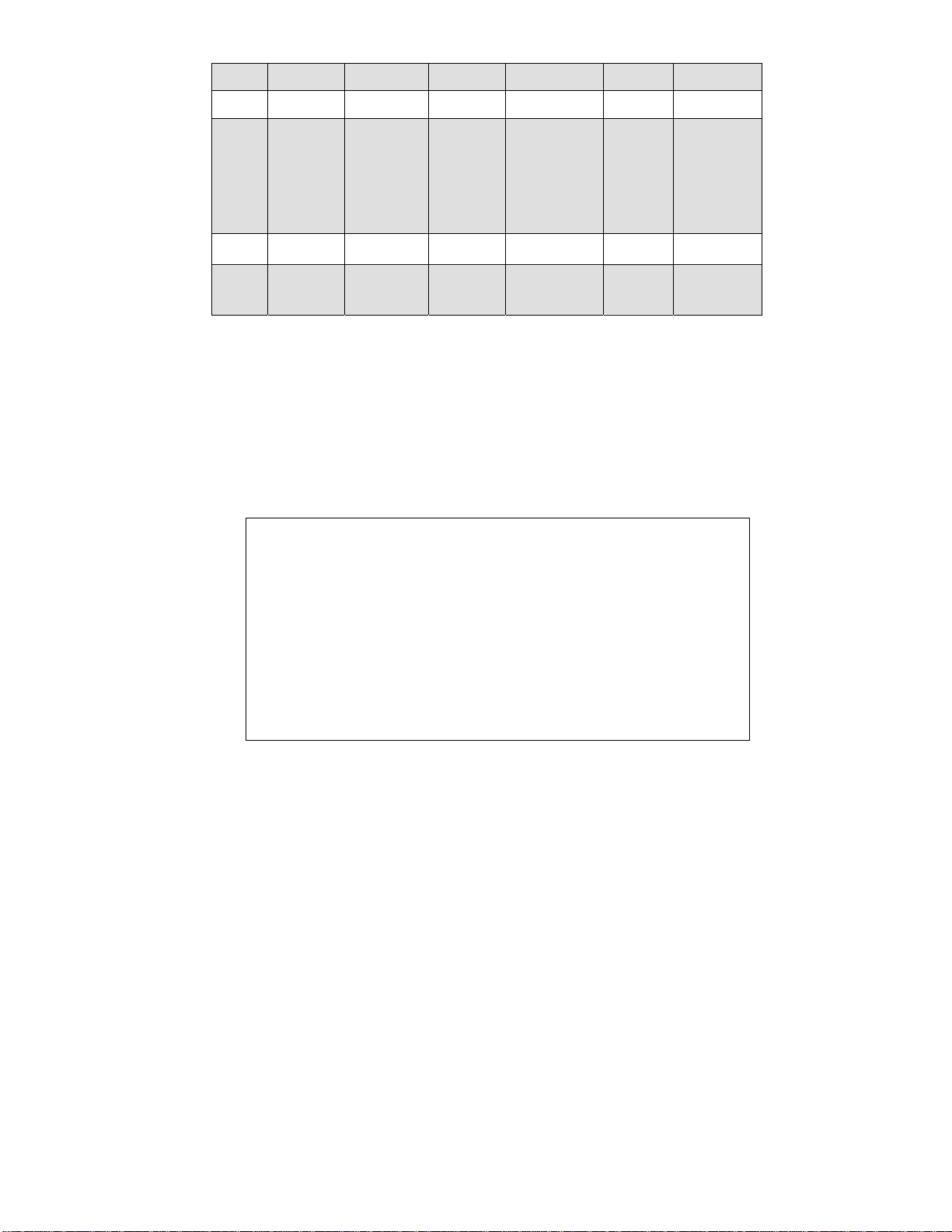

Recommended Welding Application (Table 1)

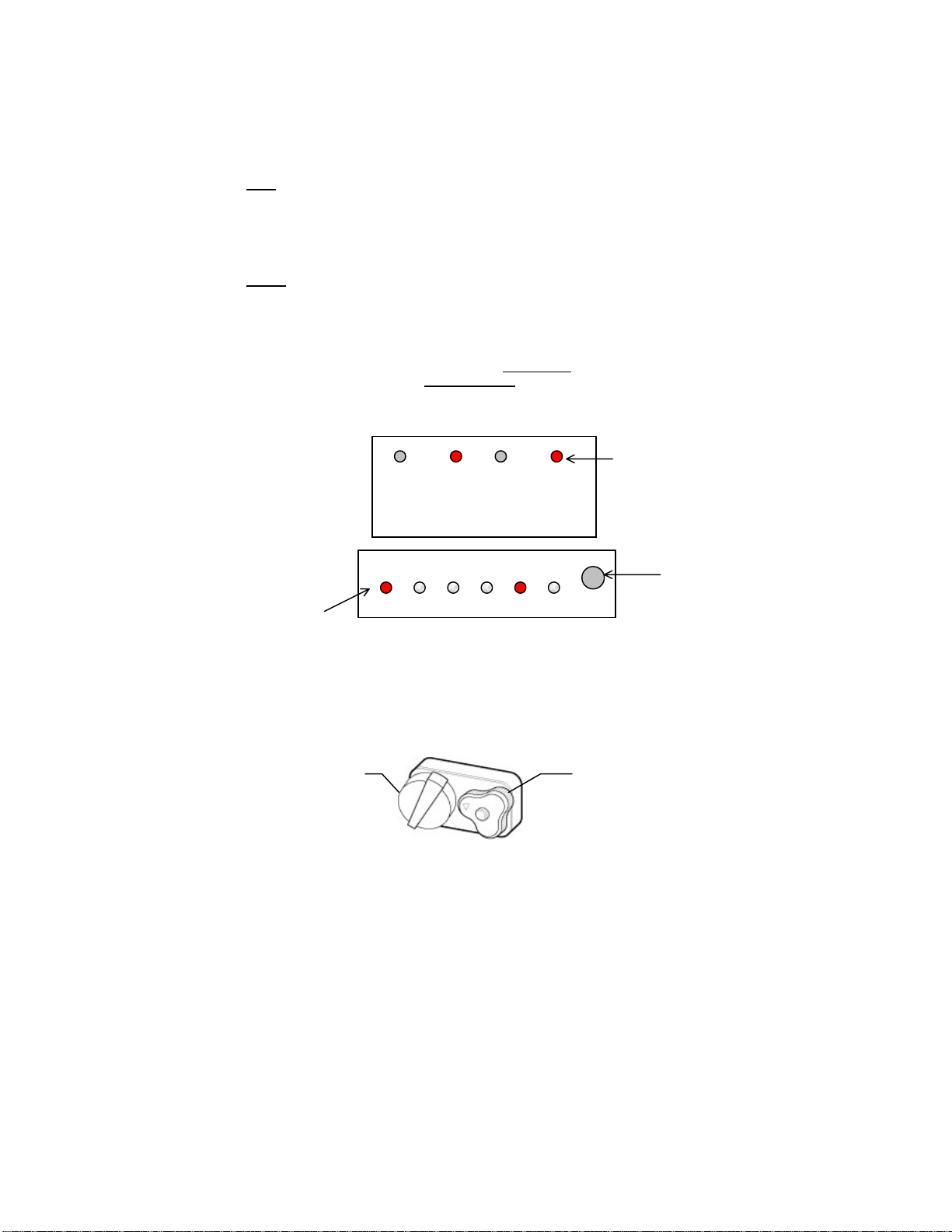

Welding Application “Heads Up” Display as seen by user

SMAC, MIG, TIG, 40 amps and above Delay 9, 10, 11, or 12

SMAC, MIG, TIG, 30 amps and above Delay TIG 9, 10, 11, or 12

Spot welding, 40 amps and above 9, 10, 11, or 12

Spot welding, 30 amps and above TIG 9, 10, 11, or 12

Note: The above settings are meant to illustrate which welding applications are

suggested for each configurable mode. Applications vary greatly so please

experiment with the many available setting combinations in order to find the best

combination of shade level, sensitivity and delay for your personal comfort and

performance efficiency.

Grinding Mode

Super Singles 240: press and hold grind/delay until LCD flickers to

indicate the change to grind mode. Press (DO NOT HOLD) and release

again to turn off (LCD will not flicker).

Xtreme X540F & X450F: press and hold sensitivity button until

“standard” LED flashes. Press (DO NOT HOLD) and release again to

turn off (LCD will not flicker).

Xtreme X540V & X450V: Press and hold grinding button until the LCD

flickers to indicate the change to grind mode. Press (DO NOT HOLD)

again to turn off (LCD will not flicker).

Industrial 540 & 450: Turn the sensitivity knob located on the outside of

the helmet clockwise to the lowest setting. This setting will work with

most grinding applications. If this setting is not low enough, press and

hold the delay/grind button until the LCD flickers. Press (DO NOT

HOLD) again to turn off (LCD will not flicker).

Industrial Xtreme: Turn the sensitivity knob located on the outside of

the helmet clockwise to the lowest setting. This setting will work with

most grinding applications. If this setting is not low enough, press and

hold the delay/grind button until the LCD flickers. Press (DO NOT

HOLD) again to turn off (LCD will not flicker).

Recommended Welding Amperage Ranges (Table 2)

(The recommended range is based darkest shade available for the particular filter model)

Filter Model Shade Recommended

Range

Singles®240, 450, and 540 12 40 to 250

XT®450 and 540 10.5 40 to 200

Super Singles 240™, Xtreme™ 450F and 540F 10.5 30 to 210

Xtreme™ 450V and 540V 12 30 to 250

Shades™ 450 and 540 12 30 to 250

Industrial

™

240 13 35 to 250

Industrial

™

450 and 540 14 35 to 300

Industrial Xtreme™ 14 30 to 300

The recommended ranges stated above are to be used as a guideline. Lower

welding amperages may be achieved and are directly influenced by the

application. Upper range amperages can vary based on the comfort level that the

user requires. Caution: Do not exceed the filter temperature range (–14 to 148

degrees F)