5

Warning

A qualified technician from the sales agency or elsewhere should only perform

installation. Imperfect installation may result in electric shocks or fire.

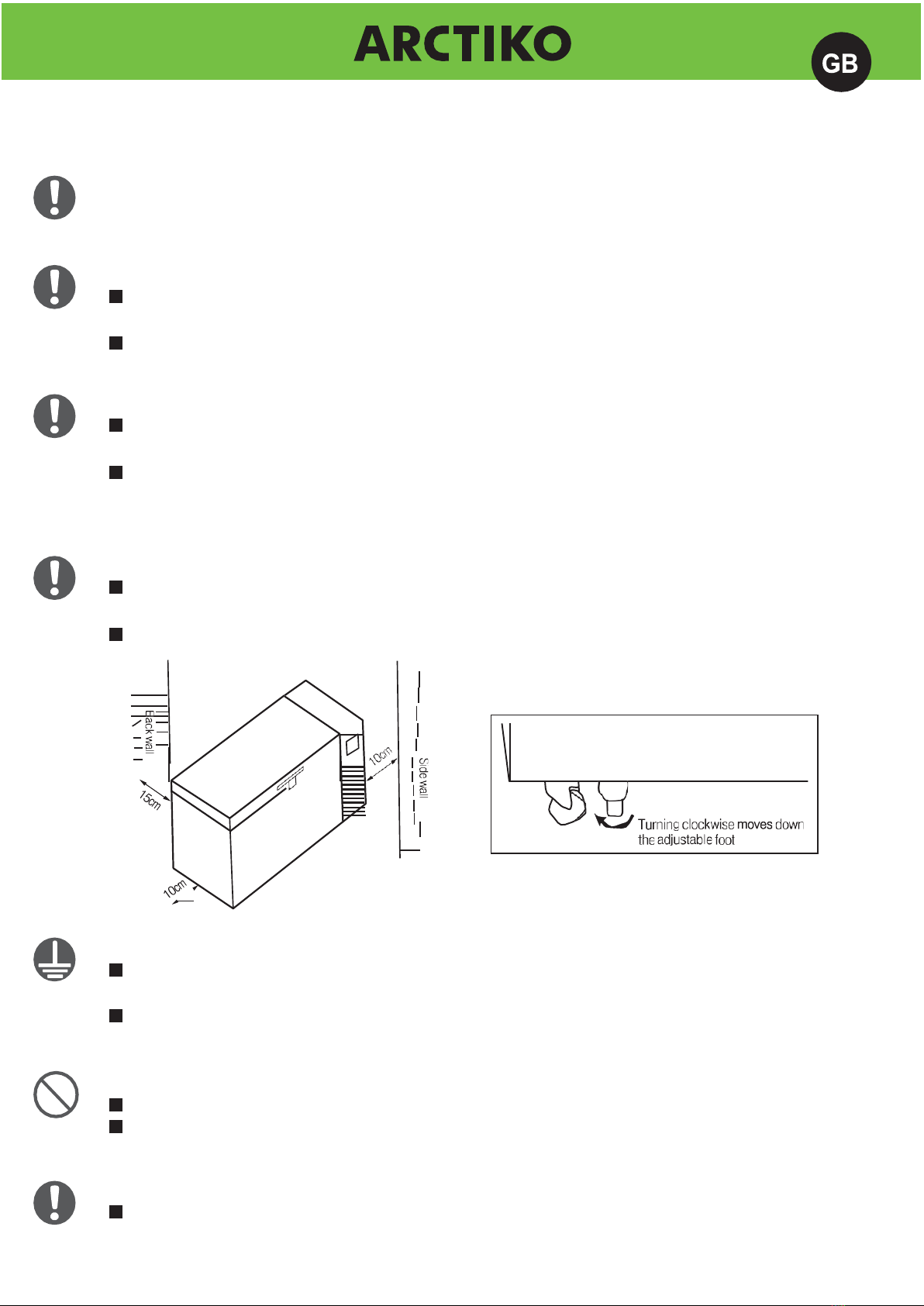

Install the appliance on a firm and level floor, which can hold the weight of the freezer.

Imperfect installation or lack of floor strength may cause the appliance to tilt or fall over,

leading to personal injury or damage to the freezer.

Be sure to ground the appliance. Do not earth it to a gas pipe, water pipe, lightning rod,

or phone cable. Imperfect grounding may cause electric shocks. (A class 3 grounding

work by an electrician is necessary.)

Use exclusive power outlet for the product. Do not cut and shorten the power cord by

yourself. Do not use extension cords, or any kind of electrical outlet divider. Failure to

follow these instructions may cause electric shocks, excessive heat-generation, or fire.

Do not use the appliance outdoors. Using the appliance in a place where it can get in

contact with water may cause electric leakage and electric shocks.

Do not install the appliance in a damp place or any other place where it may get into

contact with water. Failure to follow these instructions may ca use electric leakage

and/or electric shocks, due to lower electrical isolation.

Do not pour or spill water on the appliance or wash it with water. Failure to follow these

instructions may cause short circuits and electric shocks.

Do not touch the power plug, switches or any other electrical parts with wet hands.

Failure to follow these instructions may cause electric shocks.

Do not scratch, convert, bend, pull, or tie the power cord. Do not put any heavy objects

on it. Make sure not to pinch the cord. Any damage to the power cord may cause fire

or electric shocks.

Make sure to clean the power plug regularly. Make sure of correctly connection of the

plug into the socket. Dust or dirt on the power plug or incomplete insertion may cause

electric shocks or fire.

In case of activation of the circuit breaker, please consult your sales agency or other

qualified technician. Forceful power restoration may cause electric shocks or fire.

Do not hang on the door. The door may fall off the freezer or the freezer may fall over,

leading to personal injury, or electric leakage and electric shocks.

Do not place volatile substances or inflammables in the freezer. These substances may

cause explosions or fire.