2

INDEX ...........................................................PAGE

Before using the freezer...............................................................3

Safeguarding the environment ....................................................3

Precautions and general recommendations ........................................3

Installing the freezer..................................................................4

Inner doors ......................................................................5

Electrical connection .............................................................5

Before commissioning ...........................................................6

Start procedure ......................................................................6

Starting up the freezer............................................................6

Disconnecting the appliance ......................................................6

Functional description of the control panel .........................................6

Access code .....................................................................6

Turn/Push button.................................................................7

Main switch............................................................... 7

Menu selection .................................................................. 7

Adjustment of settings ...........................................................7

Operation description ............................................................ 7

Usage....................................................................8

Setup ....................................................................8

Manual mode ....................................................................8

Calibration of sensor ............................................................. 8

Alarm ....................................................................9

Explanation of Alarms............................................................10

The cooling system..................................................................10

CO2 Back Up ........................................................................10

Service with for - °C freezers..................... .....................

Filling procedure ................................................................11

Relocating or moving the freezer ...................................................11

Cleaning and maintenance of the freezer ...........................................11

Spare parts .........................................................................12

Disposing of the freezer .............................................................12

MENU OVERVIEW ...............................................................13-17

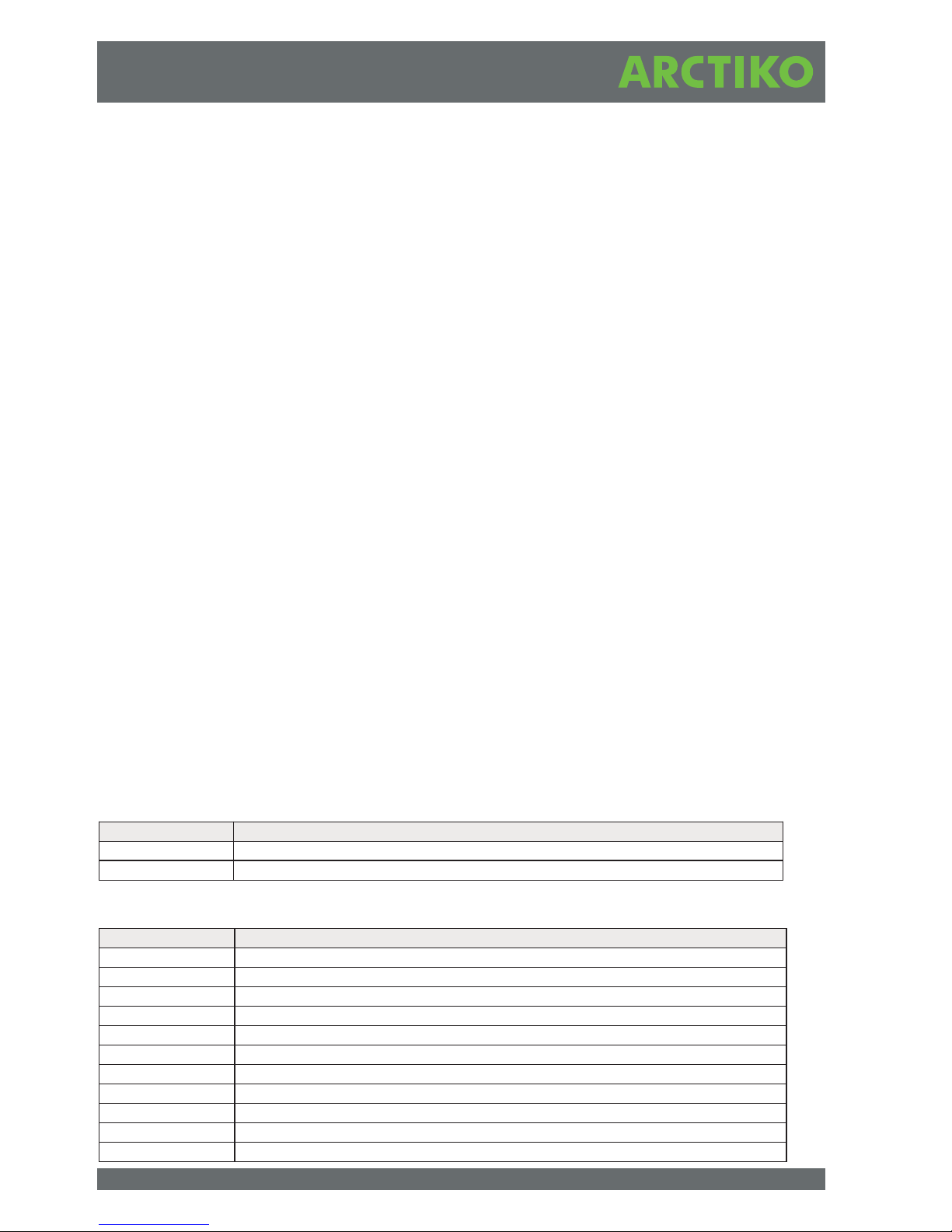

CONNECTION DIAGRAM ........................................................ 18-19