4

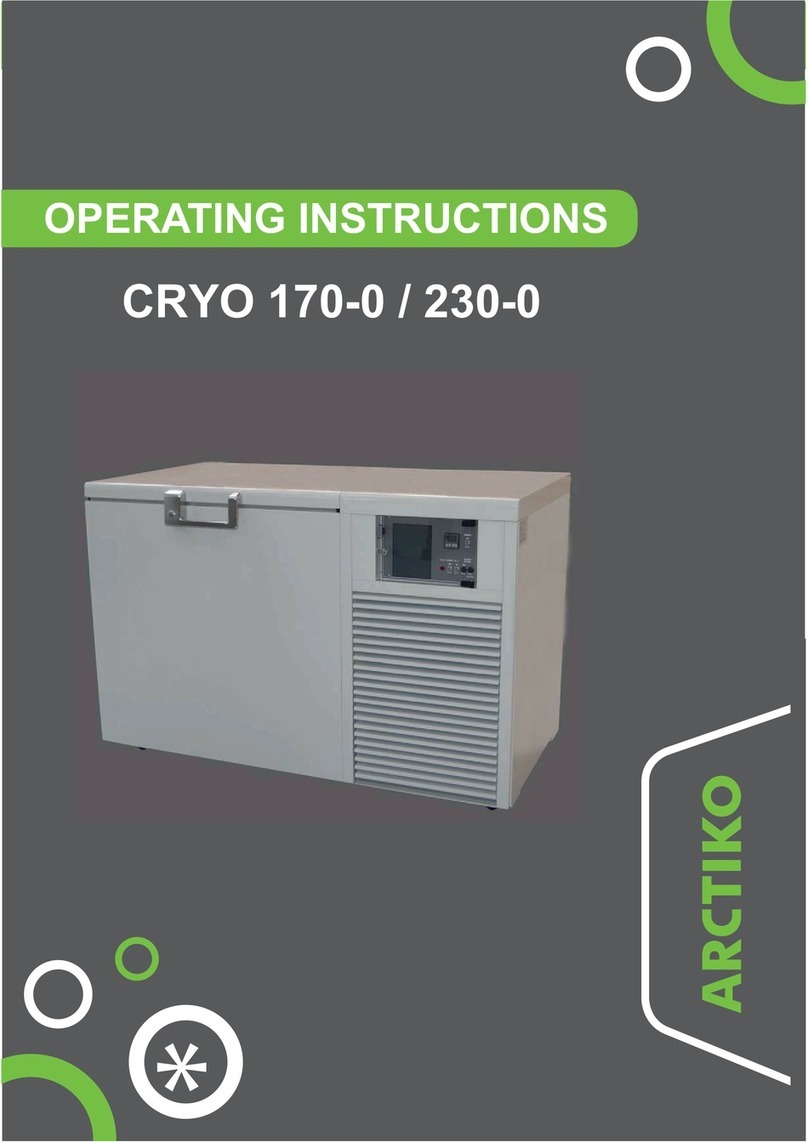

Operating Instructions

Ultra Low Temperature Freezing Box

For safety reasons, these operating instructions should be read before the freezer is commissioned.

The operating instructions should always be available to the personnel!

The drawings and symbols in these operating instructions are for safety purposes when commissioning

and using the freezer.

Instruct the personnel in the use of the freezer (Can be down to -86°C). There is a risk of frost-bite if

the contents or the sides of the inner container are touched!

In the event of breakdown or irregularities contact professional instructors or repair technicians immediately.

Installing the freezer

1. Connect the plug from the unit to power. If the electrical connection (the plug) has to be changed, always

let an authorised electrician install the freezer (read the operation instructions).

2. The freezer should be located in a dry, cool place without direct sunlight. The freezer gives off a

great deal of heat when in operation. If the ambient temperature is too high, there is a risk that the

freezer will not operate correctly. It is recommended that the room is ventilated, so that the room

temperature does not exceed 25°C at most. Class N.

3. Place the freezer on a solid and flat substrate. This will eliminate any vibration and irritating noise.

The freezer should be placed with at least 10 cm. free to the sides, at least 15 cm. free at the back,

and at least 10 cm. free to the ceiling.

4. The unit is equipped with battery backup for display and contact for remote monitoring only. Backup time

is min. 48 hours, the freezer must be connected voltage in min. 72 hours before max. battery is

available. Please note the lifetime of the battery is estimated to be 3 years. But should be checked by

authorize personnel every 6. month.

The installation should be fused with a 10 A fuse.

SUB LIDS:

The sub lids should be used at all times.

The Manufacturer is not responsible for damages

to the freezer caused by a failure to do so.

Electrical connection:

The machine meets current EU directives. Low voltage 2006/95/E.E.C.

Electromagnetic compatibility 2004/1008/E.E.C.

The machine should be given extra protection in accordance with the Electricity Supply Regulations in

order to protect the user against dangerous electric shock in the event of faults.

If the switch is for a 3-pin plug, a 3-pin plug should be used, and the conductor with yellow/green

insulation should be connected to the Earth terminal.

Data regarding voltage and absorbed power/current are given on the rating plate on the rear side of the

freezer.

Electrical connection must be made in accordance with the local regulations.

Sub lid