8/17 5084132-03

3Operational Qualification

The Operational Qualification is intended to verify the function of the appliance and its readi-

ness for operation.

The OQ is concluded if all acceptance criteria are fulfilled. If any deviations are found during

the qualification, such must be corrected and thereafter approved.

Check and verify the following parameters and fill out the below table. We recommend that the

parameters are checked app. once a year.

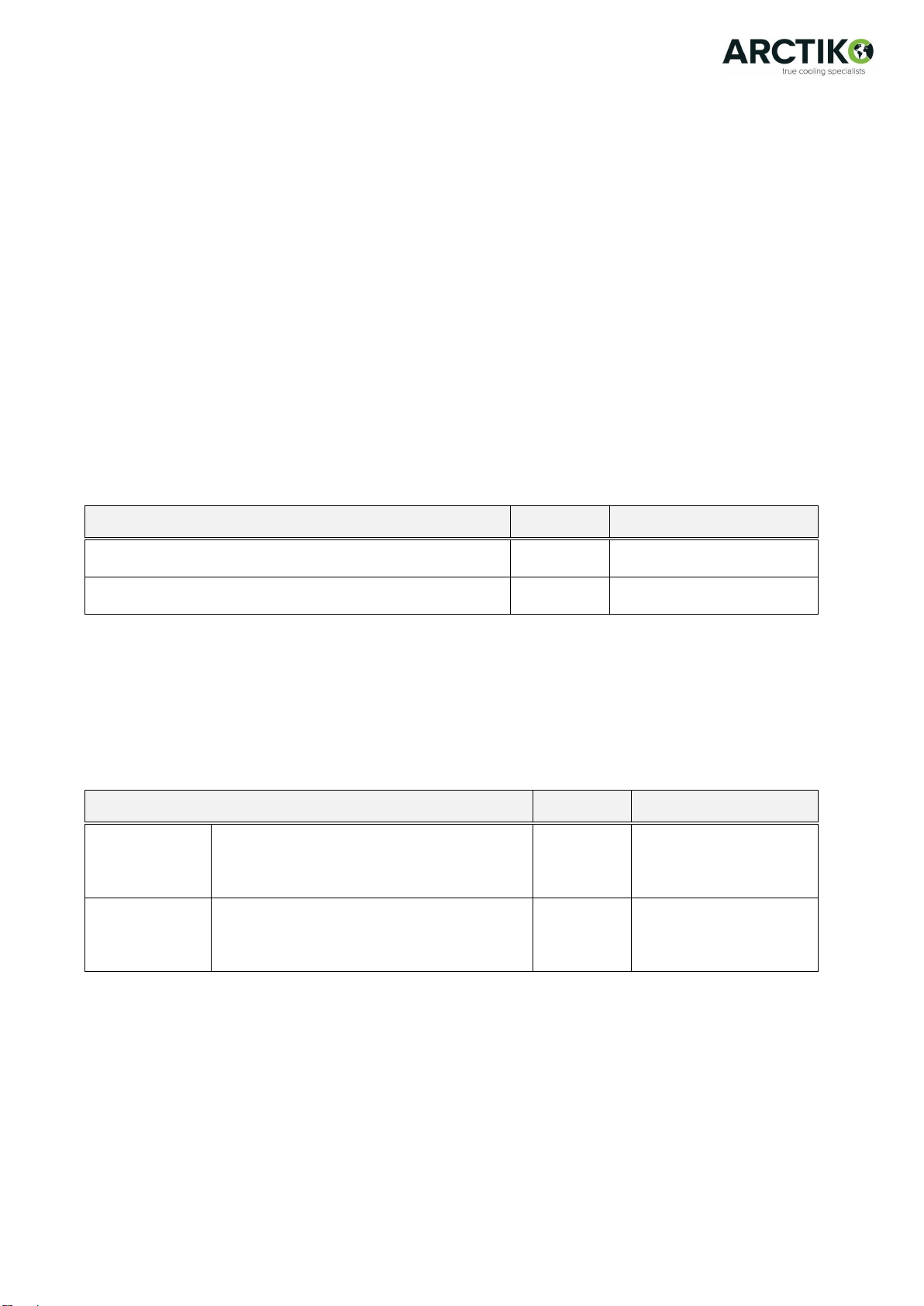

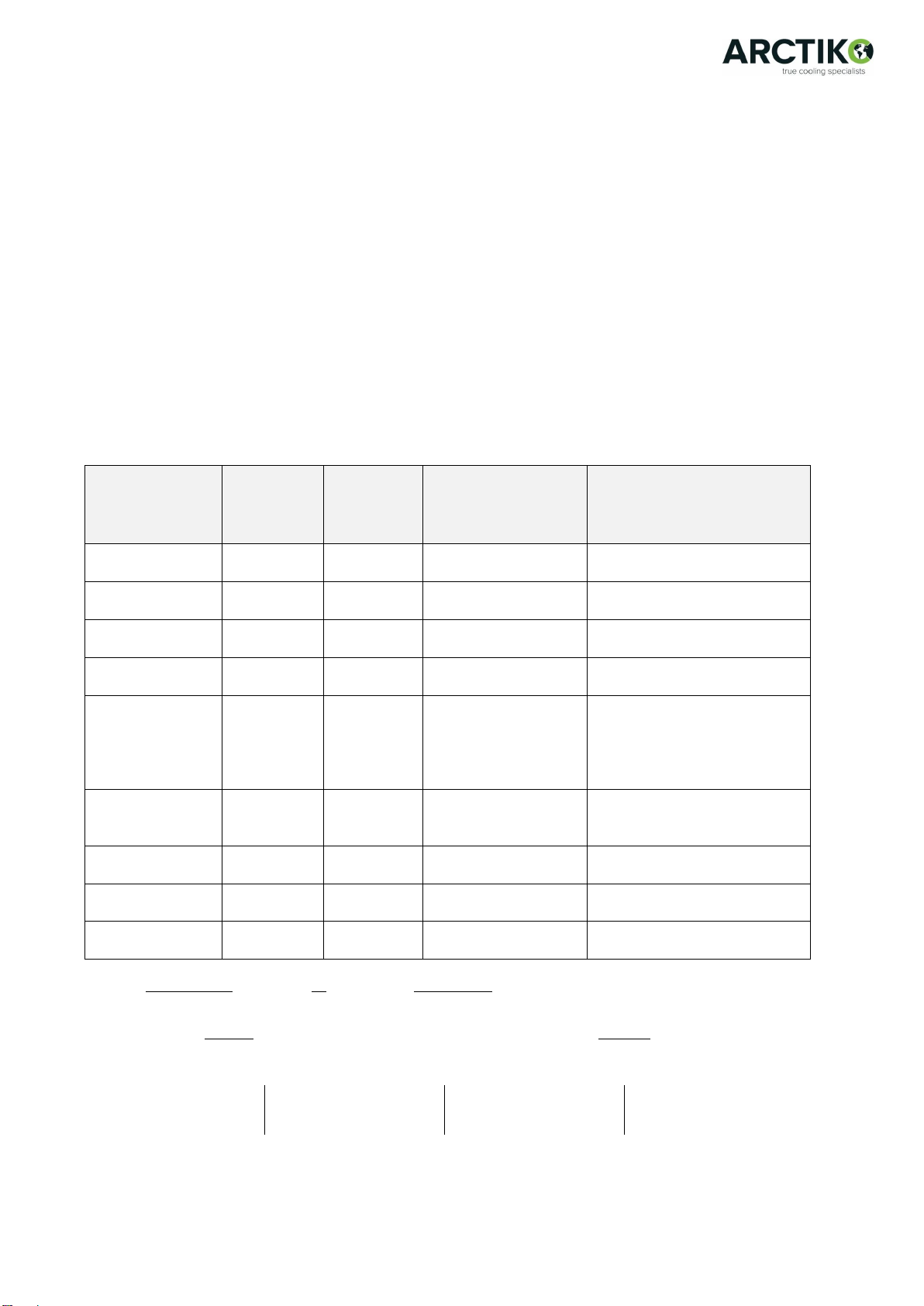

3.1 Parameter verification and adjustment

SETTINGS

LRE 700

LRE 1400

SETTINGS

LFE 700

LFE 1400

SET VALUE AND

NOTE THE VALUE

(PS)*22 22

(St) +4 -20

hysteresis (rd) 2 2

defrost (dl) N/A 6 hrs.

ture alarm by-

pass time after

defrost and door

open (d8)

0 0

after door open

(d8d)

2min. 2 min.

(AL)**4 10

(AH)**5 8

alarm delay (Ad) 5 min. 5 min.

*Use of password 22 will access all parameters. Password 0, which is stated in the user manual, will only

access a selected number of parameters.

**AL and AH are relative thresholds to the set point. The set values must be positive values.

Examples

Set point: +4°C

High. temp. alarm (AH): 5

AH alarm activation: +9°C

Set point: +4°C

Low. temp. alarm (AL): 3

AL alarm activation: +1°C

Set point: -20°C

High. temp. alarm (AH): 7

AH alarm activation: -13°C

Set point: -20°C

Low. temp. alarm (AL): 6

AL alarm activation: -26°C