B-1 PRODUCT DESCRIPTION B-1

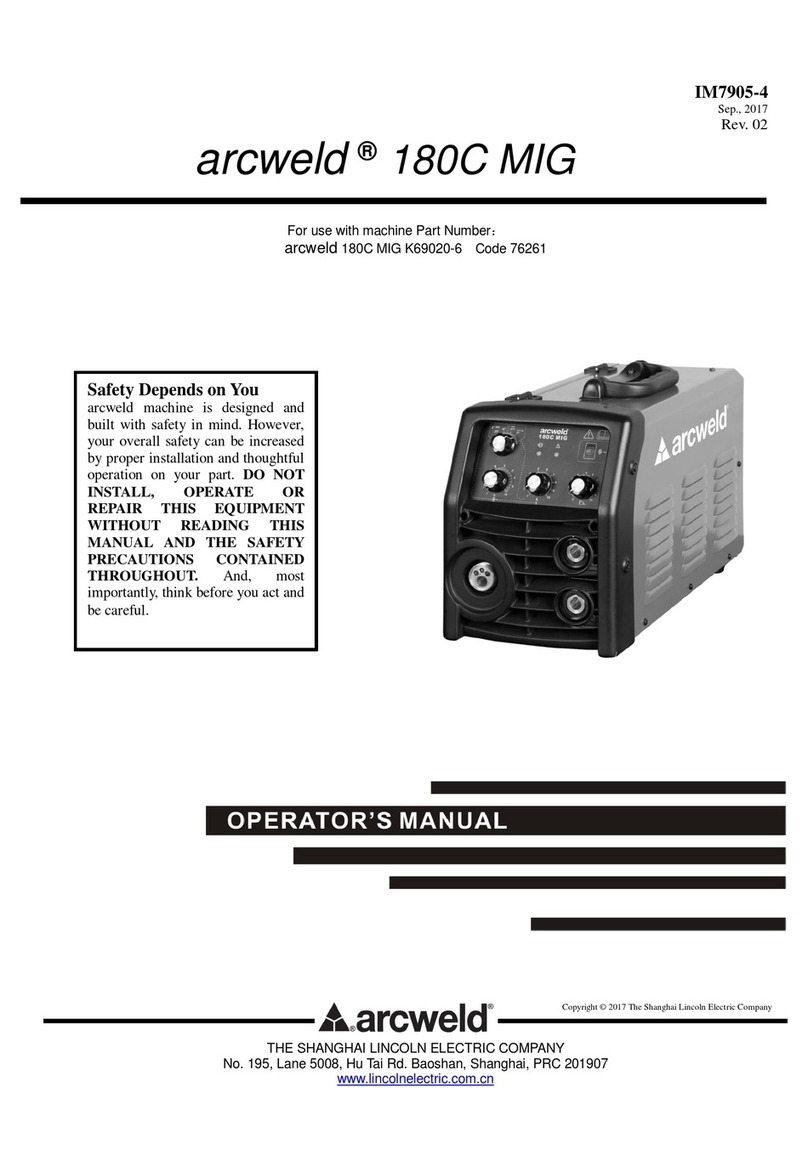

arcweld®210C/250C MIG inverters are multi-purpose welding power sources. Capable of MIG welding

(both gas-shielded and gasless flux-cored welding), stick and TIG welding of mild and stainless steel

materials. The welding output has been optimized for MIG, STICK, TIG & FCAW welding processes.

They are an ideal choice for fabrication, maintenance / repair, automotive, rural and DIY. Supplied as a

Ready-To-Weld TM package with all options for MIG and STICK welding. Optional TIG torch available

separately. The machines are light and portable which makes them very popular in DIY and

semi-professional market.

The highlighted characteristics of arcweld®210C/250C MIG Inverter MIG/MMA/TIG Welder:

Compact size and light weight, it is widely used in maintenance and fieldwork.

Provided with input voltage compensation covering ±10% variation and a control circuit

reaction speed of less than 1 mSec.

Optimum arc characteristics are maintained over a broad range of operating conditions.

Suitable for solid and flux-cored and aluminium wires. The wire diameter range is between

Φ0.6~Φ1.2mm

Convenient polarity change connection. Outer connection makes it quick, safe, simple and

reliable.

MMA (stick welding) suitable for welding all electrodes including cellulosic electrodes.

Built-in VRD voltage reduction in MMA, MIG and TIG modes.

Touch Start TIG RDC operation allows you to strike the arc without high frequency or tungsten

contamination.