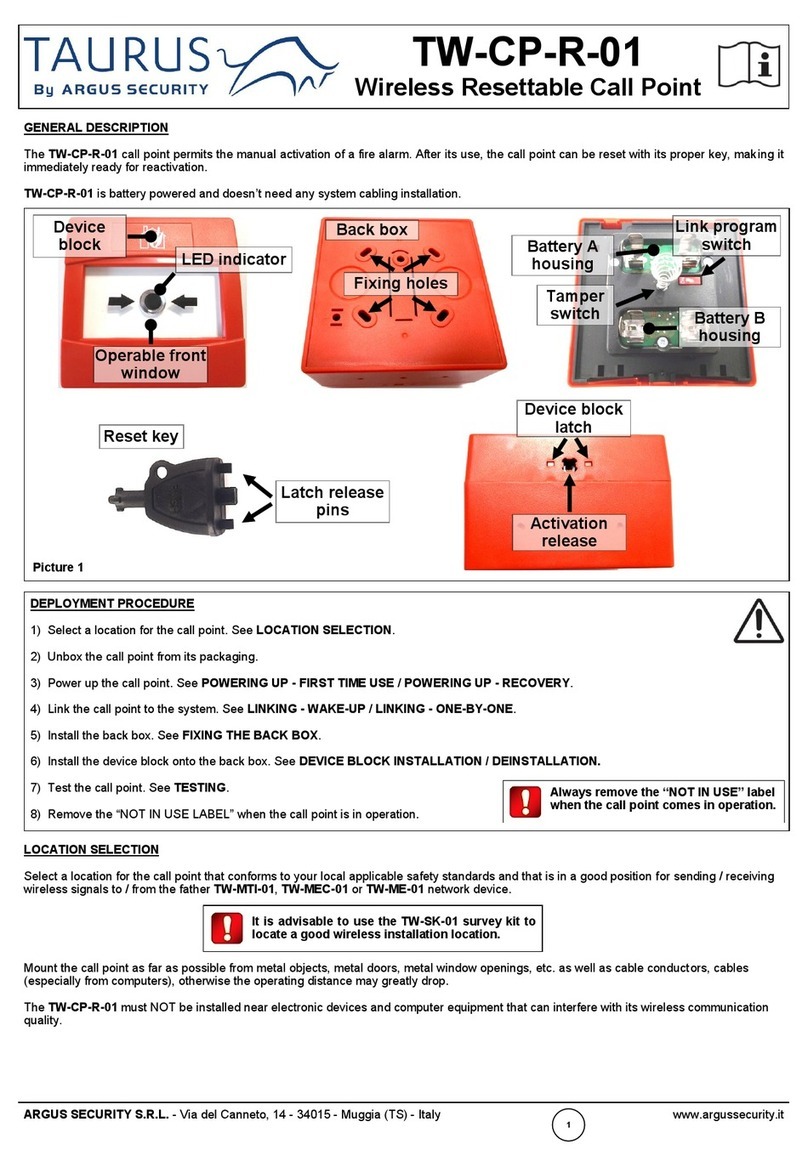

COMMUNICATION QUALITY ASSESSMENT

It is possible to assess the radio communication quality of the wireless call point with the translator or expander module by using a

test feature built into the device. After successful programming-linking operation, by changing the link-program switch to the ON

position the device’s LED indicator will start blinking according to table 3.

Always remember to return the switch to the 1 position after the assessment operation: the device will NOT function

correctly whilst the switch is set on the ON position.

Communication quality Assessment Device’s indication

No connection Fail Two red blinks

Link margin is less than 10 dB Poor One red blink

Robust communication with link margin from 10 dB to 20

dB Good One green blink

Robust communication with link margin over 20 dB Excellent Two green blinks Table 3

WIRELESS CALL POINT PLACEMENT

For specific information regarding call point’s spacing, placement and special applications

refer to your specific national standards.

It is strongly advised to mount the device away from metal objects, metal doors, metal

window openings, etc. as well as cable conductors, cables (especially data cables), other-

wise the operating distance may greatly drop. The device should not be installed near

electronic devices and computer equipment that can interfere with the reception quality.

1) Select the position of the call point before installing and fixing its wall mounting back box.

Verify, from that position, that the communication between the device and the wire

to wireless translator or the wireless expander is correctly established and

working (see the COMMUNICATION QUALITY ASSESSMENT paragraph).

2) Install and fix the correctly oriented back box, in the selected position, with the screws

provided (picture 8).

3) Insert the correctly oriented front operating element onto its back box; see below the INSTALLING THE FRONT OPERATING

ELEMENT paragraph.

Picture 8 - position of

the holes for the screws

TESTING THE CALL POINT

In order to test the functionality of the installed wireless call point just press where marked on the call point’s operating window (see

paragraph ACTIVATION). When the call point is activated the following events will occur:

1) a rectangular visual indicator drops into view under the left-top corner of the device's transparent front window

2) an activation message is sent by wireless to the wire to wireless translator module then, successively, through the wiring loop to

the alarm system’s control panel

3) an alarm condition is initiated by the control panel

4) the call point’s visual LED indicator starts blinking indicating its activated status (see “Alarm activation”, table 2).

After each test the device must be reset (see the CALL POINT RESET paragraph).

All devices must be tested after installation and, successively, on a periodic basis.

Picture 12 - operating

element reset

MAINTENANCE

1) Before starting any maintenance work (e.g. batteries substitution), disarm the system, in order to avoid accidental and unwanted

tamper detection conditions

2) remove the front operating element from its wall mounting back box

3) perform the necessary maintenance operations

4) after the device has been serviced, reinstall it correctly onto its back box, re-arm the system and check correct operation as

described under the TESTING THE CALL POINT paragraph.

FRONT OPERATING ELEMENT REMOVAL

In order to remove the call point’s front operating element from its wall mounting back box, the pegs on the top of the reset key must

be inserted into the two release holes located under the call point; push the pegs into the holes until the front unlocks (picture 10).

During this operation be careful not to twist the reset key or drop the device on the floor.

TAMPER DETECTION SPRING

The wireless call point front operating element has a tamper switch spring fitted on the rear, so that if it is removed from its wall box it

will send a tamper message to the control panel (see picture 4).

CALL POINT RESET

To reset the wire to wireless from an activated condition, it is necessary to:

1) insert the reset key into its entry situated under the front device block and turn it counter-clockwise until the operable front window

unlocks (picture 12)

2) send a reset command from the control panel.

DISCHARGED BATTERIES

If one or both batteries are discharged, this condition is signaled locally by visual LED indicator (table 2), by the wire to wireless

translator and, if implemented, by the system’s control panel. Both must be replaced together.

The device should be removed from its back box and transferred to the safe area before batteries are removed and

replaced to enhance safe handling.

INSTALLING THE FRONT OPERATING ELEMENT

In order to complete the installation, the front operating element must be securely installed onto the wall-mounted back box. In order

to assemble correctly fit the front as illustrated in picture 9.

ACTIVATION

The wireless call point is activated by pressing the where marked on the transparent window on the front of the device as shown in

picture 11.

Picture 9 - front

operating element

assembly to its

wall mounting

back box

Picture 10 -

front device

block removal

from its wall

mounting back

box

Picture 11 - call

point activation

www.argussecurity.itARGUS SECURITY S.R.L., Via del Canneto, 14 - 34015 - Muggia (TS) - Italy

WARNINGS AND LIMITATIONS

Our devices use high quality electronic components and plastic materials that are highly resistant to

environmental deterioration. However, after 10 years of continuous operation, it is advisable to replace

the devices in order to minimize the risk of reduced performance caused by external factors. Ensure that

this device is only used with compatible control panels.

Detection systems must be checked, serviced and maintained on a regular basis to confirm correct

operation. Smoke sensors may respond differently to various kinds of smoke particles, thus application

advice should be sought for special risks. Sensors cannot respond correctly if barriers exist between

them and the fire location and may be affected by special environmental conditions. Refer to and follow

national codes of practice and other internationally recognized fire engineering standards.

Appropriate risk assessment should be carried out initially to determine correct design criteria and updat-

ed periodically.

Care must be taken not to generate any electrostatic charge on the body of the device

Clean only with a lint-free damp cloth and do not use any cleaning solvents

WARRANTY

All devices are supplied with the benefit of a limited 3 year warranty relating to faulty materials or manu-

facturing defects, effective from the production date indicated on each product. This warranty is invalidat-

ed by mechanical or electrical damage caused in the field by incorrect handling or usage. Product must

be returned via your authorized supplier for repair or replacement together with full information on any

problem identified. Full details on our warranty and product’s returns policy can be obtained upon re-

quest.

ARGUS SECURITY S.R.L.

Via del Canneto, 14

34015 Muggia (TS)

Italy

16

SG2210CPR

EN 54-25:2008

EN 54-11:2001 + A1:2005

SGCP100-IS

For use in compatible fire

detection and alarm system

Type A for indoor use only

3

4

0051 / 0598

II 1 G

IMPORTANT NOTES!

Programming is considered to be completed successfully only if there is an indication of programming success on the

device and on the wire to wireless translator module or on the window of the Wirelex program.

Do not fit the front operating element onto the back box, so to press the tamper spring, before programming and linking to

the wireless system is totally completed: communication problems may rise successively.

Generally speaking: make sure, during the programming-linking phase, that the tamper spring is not pressed at all!

See the TAMPER DETECTION SPRING paragraph for more information on the tamper spring.