Disclaimer

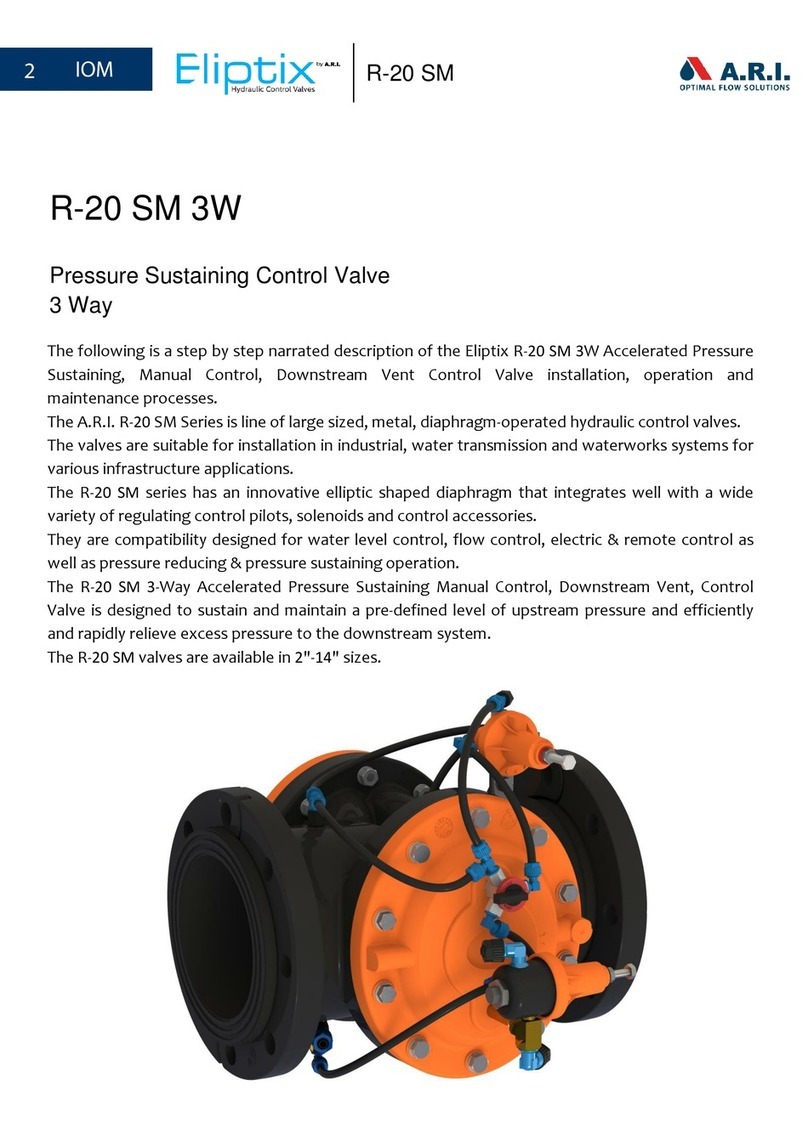

This document is an Installation, Operation and Maintenance (IOM) manual for A.R.I. Flow Control Accessories Ltd. (A.R.I.) products.

The information enclosed herein contains restricted, privileged, proprietary and confidential information, intended only for usage by

authorized A.R.I. technicians. If you are not a qualified technician, you must not take any action in reliance upon this document,

unless otherwise permitted in writing by A.R.I.

A.R.I. has made every effort to ensure that this document is accurate; A.R.I. disclaims liability for any inaccuracies or omissions that

may have occurred.

All the procedures, drawings, pictures and/or any other information provided in this document are presented as general information

only; they can be altered, removed or changed without A.R.I.'s prior written approval. A.R.I. makes no commitment to update or

keep the information in this document current and/or up-to- date, and reserves the right to make improvements, alterations and/or

modifications to this document and/or to the products described in this document, at any time without providing any notice with

respect thereto. Nothing in this Disclaimer derogates in any way whatsoever from the confidential nature of any document enclosed

hereto, including for avoidance of doubt, any mistake or clerical error or other error. None of the procedures provided in this

Disclaimer and/or in any document enclosed hereto may be used in any form or by any means without the prior written consent from

A.R.I. If you received this Disclaimer and/or in any document enclosed hereto in error or by mistake or if this Disclaimer and/or in any

document enclosed hereto is not intended for you, please notify A.R.I. in writing immediately.

A.R.I. assumes that all users understand the risks involved within this Disclaimer and/or in any document enclosed hereto.

A.R.I. accepts/assumes no liability whatsoever, whether caused by: accessing and/or relying upon this Disclaimer and/or in any

document enclosed hereto including without limitation any links, procedures or materials.

A.R.I. shall NOT assume any liability for any costs, direct or indirect, including loss of income, loss of profits and/or goodwill, legal

actions and/or damages of any kind whatsoever including any, damages accidents, equipment damage or bodily injury resulting from

and/or related to any of the following:

product has not been duly installed and thereafter maintained in strict compliance with its designated Maintenance

Instructions and/or any other installation and operation manuals provided by A.R.I. for the product and/or applicable

ordinances and/or codes;

Repairs made in and to the products by personnel not authorized by A.R.I.

Maintenance or repairs using parts or components other than those specified by A.R.I. and in their original condition.

Operating the products in ways other than the operating procedures described in the manuals provided by A.R.I., or resulting

from not following the cautionary remarks and warnings in the product manual.

Improper storage, workplace conditions and environmental conditions which do not conform to those stated in the Product

manual.

Fires, earthquakes, floods, lightning, natural disasters, or acts of God.

A.R.I. does not warrant and hereby disclaims any express or implied warranties that the product will work properly in environments

and applications other than its original design purpose, and makes no warranty and representation, either implied or expressed, with

respect to the quality, performance, merchantability, or fitness for any other particular purpose.

Except as provided herein and to the full extent permitted by law, A.R.I. shall not be responsible and/or liable for direct, special,

incidental or consequential damages or loss resulting from any breach of the above or under any other legal theory.

This document does not replace any certified drawing, procedure or information provided by A.R.I. in reference to a specific

customer, site or project.

All rights reserved.