2

Te e

C-Tube

Elbow

New Type Tubing Old Type Tubing

Fitting A

Check Mark

Fitting B

Fitting A

Groove

(has to be on top)

Fitting

Orifice

(Reduced Port)

Orifice

(Reduced Port)

Te e Te e

Elbow Elbow

Fitting B

B-Tube

Fitting A

A-Tube

Relieving Pressure Color Code

3to21psig Yellow

14 - 157 psig Green

143 - 200 psig Brown

Spring Chart

Confirmthevalvesbeforeandafter theregulatorare

closed, including the valve in the control pipe. Also, make

surethat nopressure anddrainage remainsinsideofthe

regulator.

Disassembly

Pilot valve (Figure 3-1)

1. Slightly loosen lock nut (28) and turn adjusting screw

(27)counterclockwise torelease adjustingspring (24)

(nocompression).

2. Remove bolts(37)of springhousing (3). Removethe

springhousing, spring,topspring plate(25), bottom

springplate (26),and pilotdiaphragms (23).

3. Removeseal bellows(61) usingaringspanneror

socketwrench andremove gasket(62),pilot valve(63),

andpilot valvespring(64).

4. Removepilot valveseat (65)using asocketwrench.

Main valve (Figure 3-1)

1. RemovepipeA(34)at fitting(30A) andtee (33).

2. Fornominal sizes1/2” to1-1/2”, removebolts(38) of

pilot body (2). Dismount the pilot body from the body

(1). Andremove screen(15), springplate (14),main

valvespring (13)and mainvalve(6). Forseries2” to

6”,remove boltsof adapterplate andadapterfrom the

mainbody (1). Removemainvalve spring(13)and

mainvalve(6).

Main diaphragm (Figure 3-1)

1. Removepipe C(36) attee(33).

2. Removebolts (41)of bottomdiaphragmcase(5).

Dismountthe bottomdiaphragmcase,maindia-

phragms(12), retainer(11),and spindle(9). Checkthat

spindlemoves upand downfreely andthat noparticu-

late or scale build-up is obstructing its performance.

Reassembly

1. Checkthat thereis nodamage onthemain valve,

mainvalve seat,pilot valve,and pilotvalveseat. If any

scratches exist on the seating surface of valve seat,

they may cause an increase in outlet pressure and

excess temperature. When any scratches exist on

themain valveand valveseat,carryoutlapping to

remove them. If it is not possible to remove them,

replace with new parts. When any scratches exist on

thepilot valveand valveseat,replacewithnew parts.

2. Movethe slidingsection (pilotvalve, mainspindle,

etc.) two to three times and confirm they move

smoothly. If they do not move smoothly, original

performancemay beaffected.

3. Replacegaskets withnew oneswhen disassembling.

Steam may leak if gaskets are reused.

4. Afterthe mainvalve, spring,and springplate are

assembledcorrectly, mountthe maindiaphragm.

Incorrect assembly may affect the original perfor-

mance.

5. Carry-outre-assembling inreverseorder ofdisassem-

bling. Tighten all hexagon bolts evenly on each bolt in

turnof diagonalposition. When re-assemblingthe

productin thewrong order,proper functionmay notbe

possible. Uneventighteningof boltsmay cause

leakageof steam.

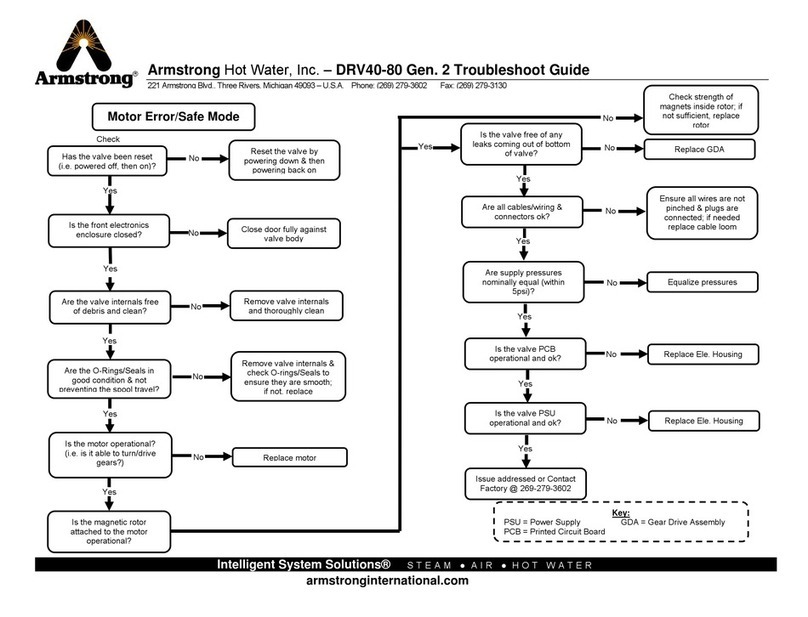

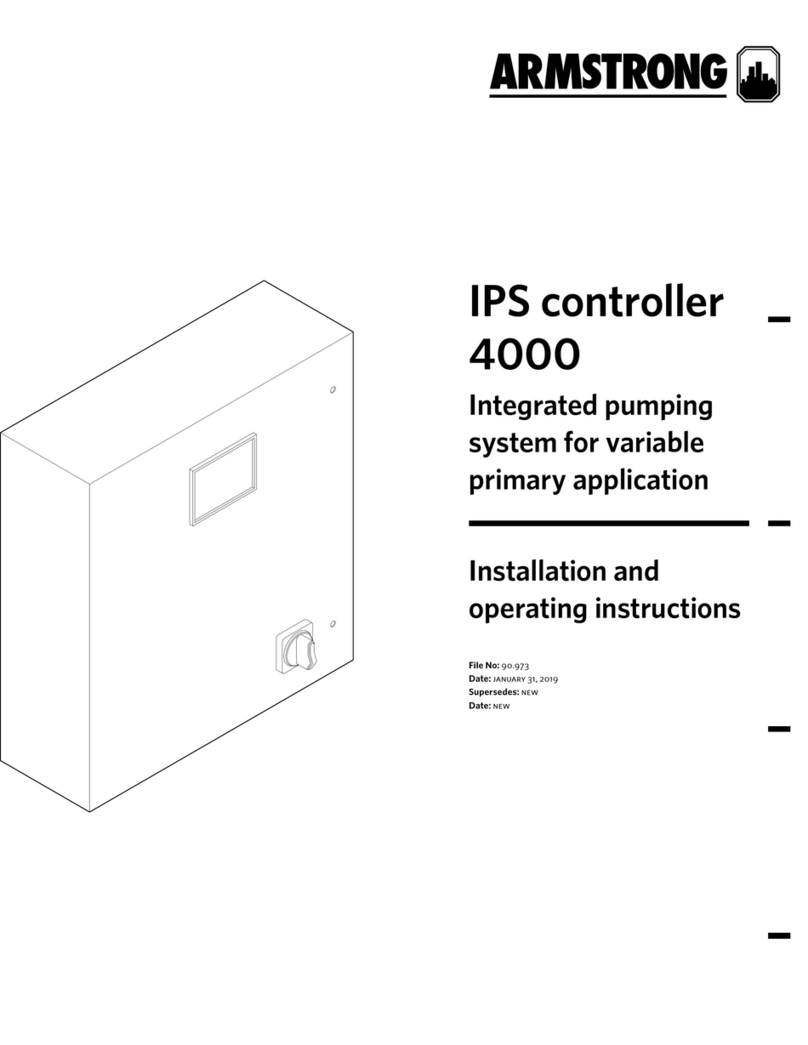

New Tubing Set-Up

Theexternal tubingfor ourGP-2000Rseries hasbeen

modifiedto enhancethe performanceof thesemodels.

Thefollowing explainsthedifferencebetweenthe oldand

new tubing assembly. It is important to have these fittings

inthecorrect locationin orderto getoptimum performance

from these valves. It is very important that the old and new

tubing assemblies are not mixed. The location of all

fittings is critical and should not vary from the assembly

instructions.

New Type Tubing

Figure 5-1

Note: Fittings and tee are to be located in similar positions

forall GP-2000models.