Display 7-Segment LED installation

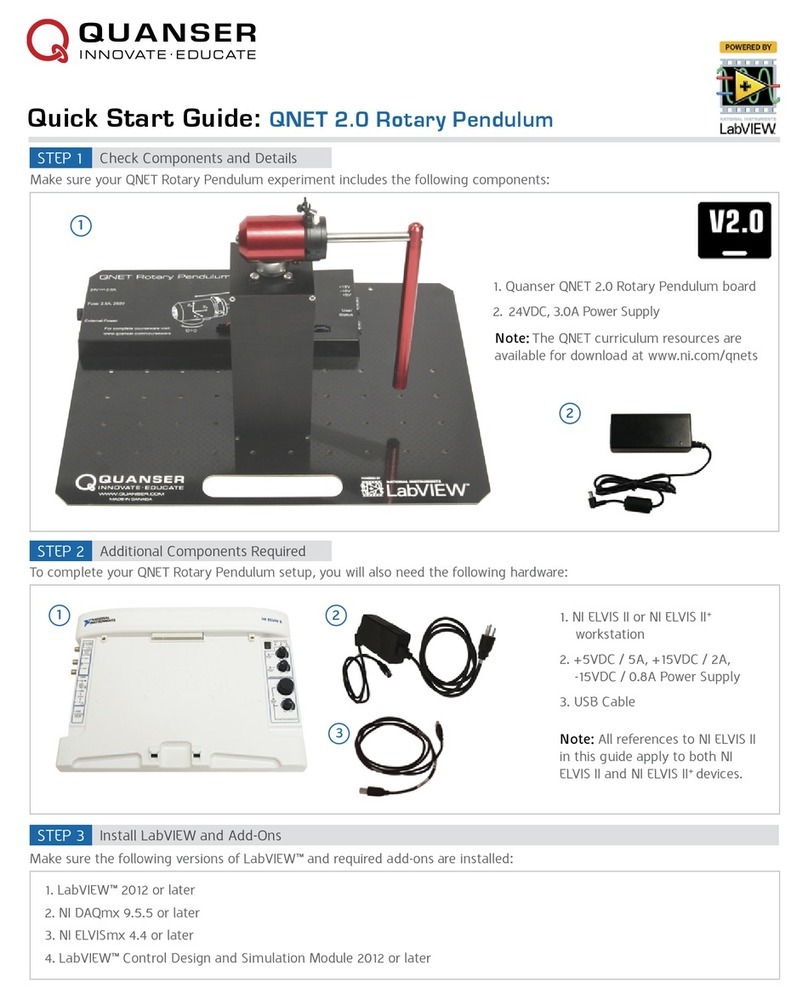

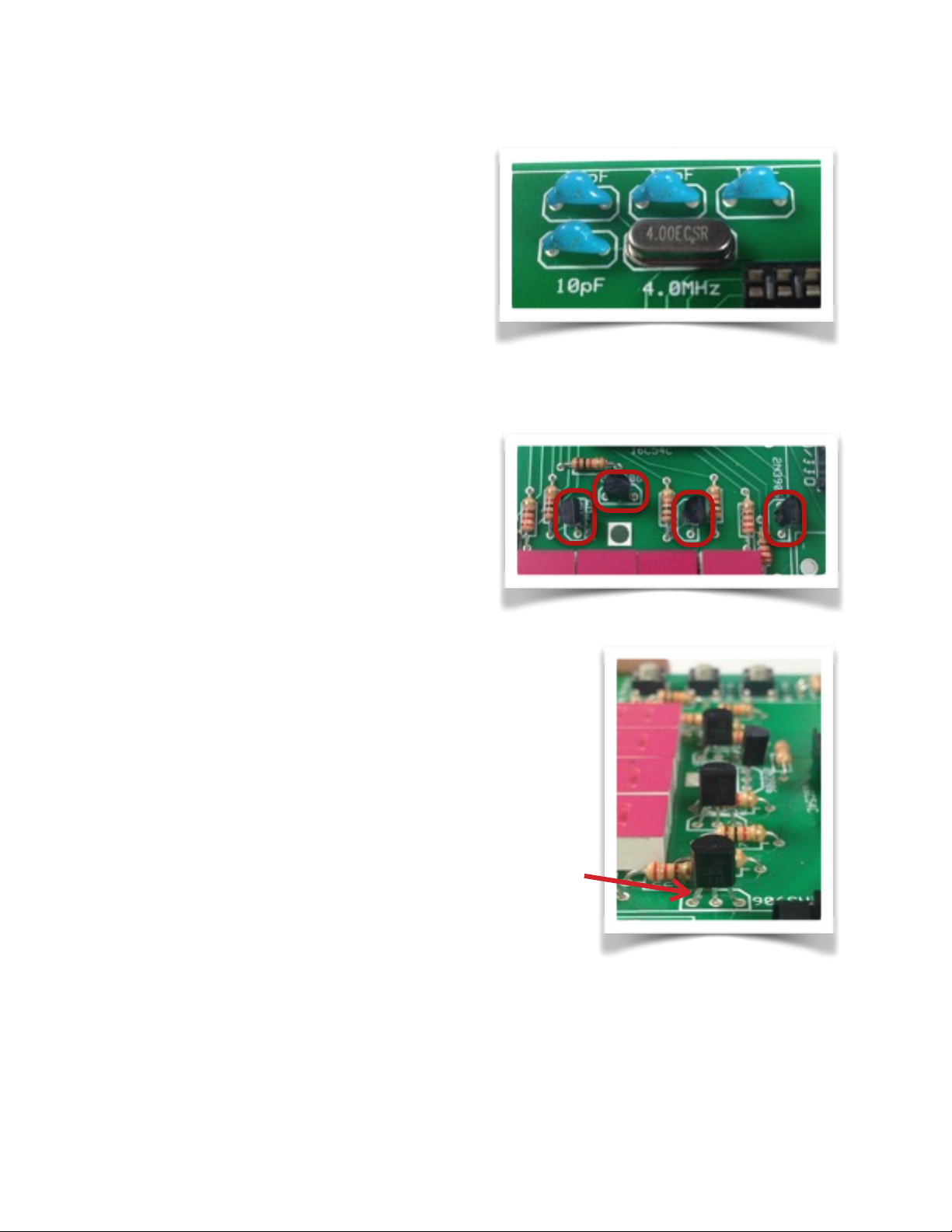

Locate the four 7-segment LEDs that

make up the time display. The pins on

the back of these LEDs are not

arranged symmetrically — this helps

you install the LEDs correctly. If you try

to force the LEDs in the wrong

direction, you can bend the pins and

damage the LEDs.

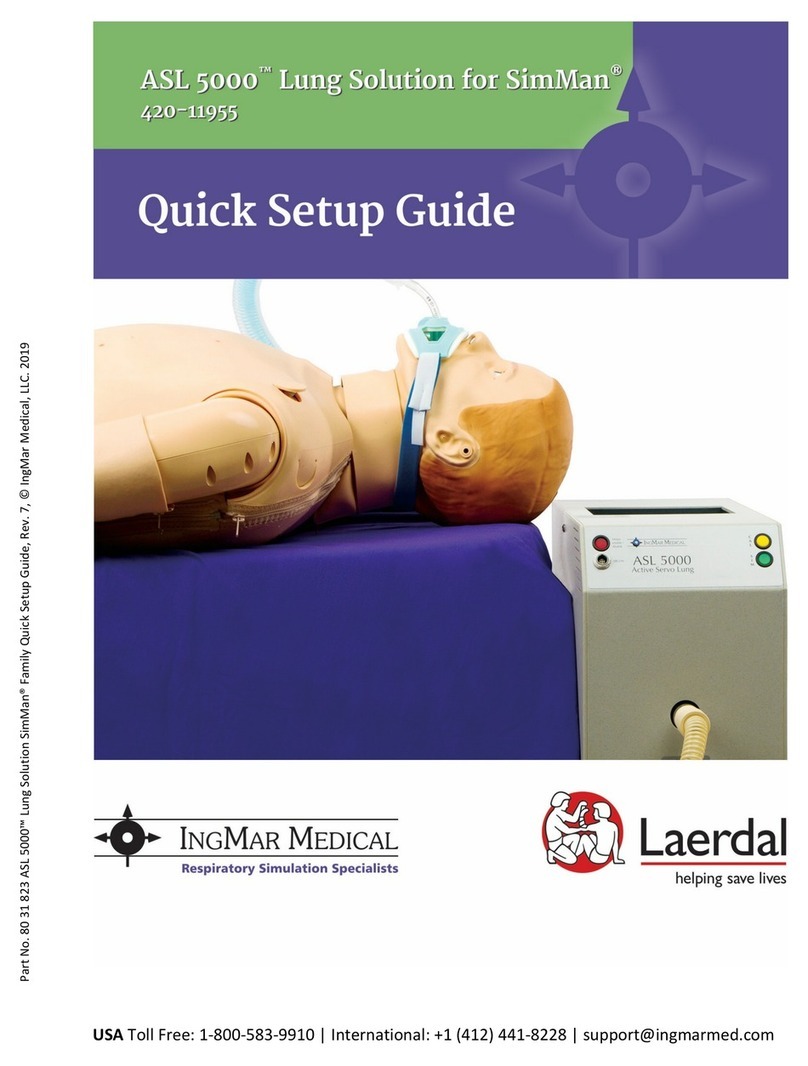

Notice that the 10s-minute digit on the

board is upside down. This allows the

decimal point of that LED to function

as the upper dot of the colon

separating the hour and minute digits

on the display. (Pretty clever, huh?)

Install four 7-segment LEDs as

indicated on the board (Remember,

the third LED from the left is installed

rotated 180° from the others!). Don’t

force the LED pins into the mounting

holes.

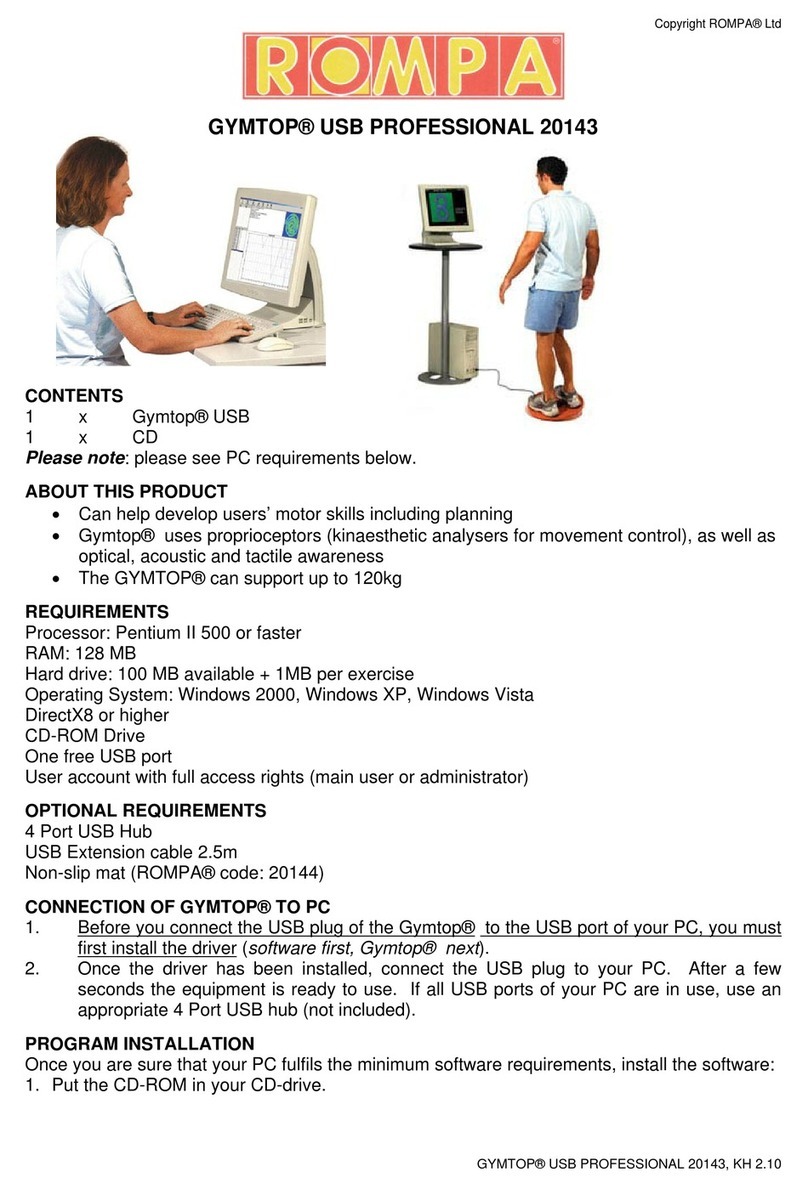

Mount the LEDs by tack soldering

opposite corner pins, as you did with

the IC socket. Press on each LED as

you heat the tacked pins to ensure the

LEDs are flush with the board.

When all four LEDs are flush and

straight, solder the remaining pins and

trim the excess pin lengths.