Contents

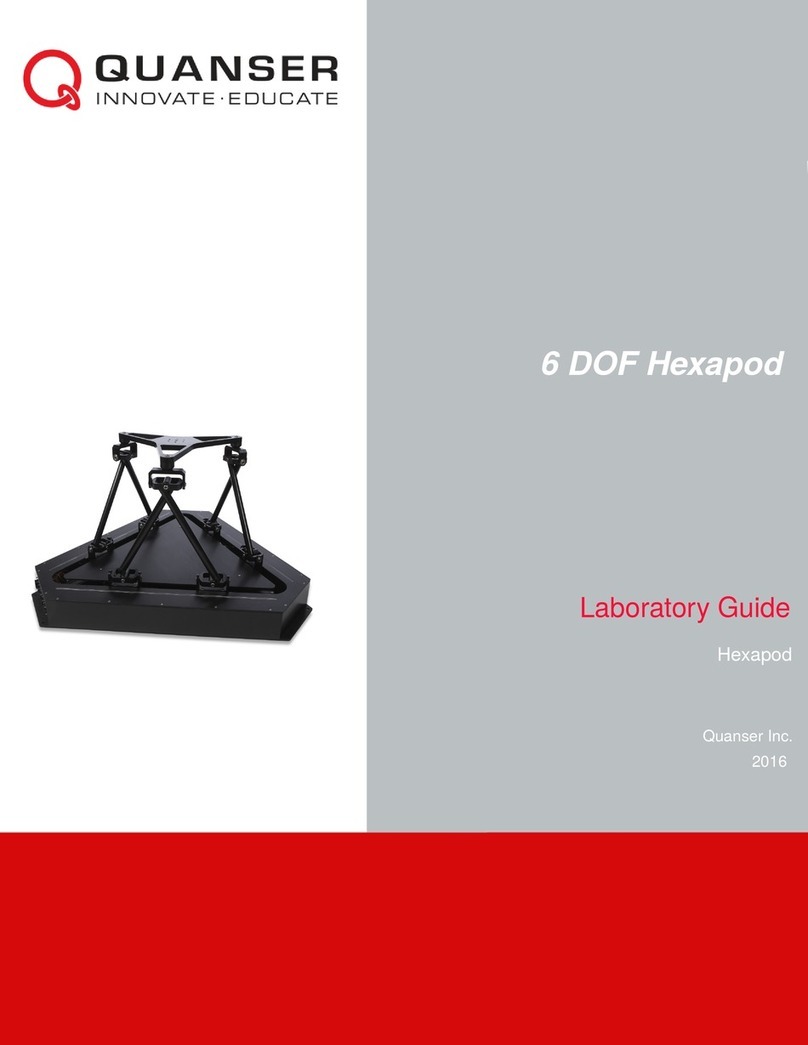

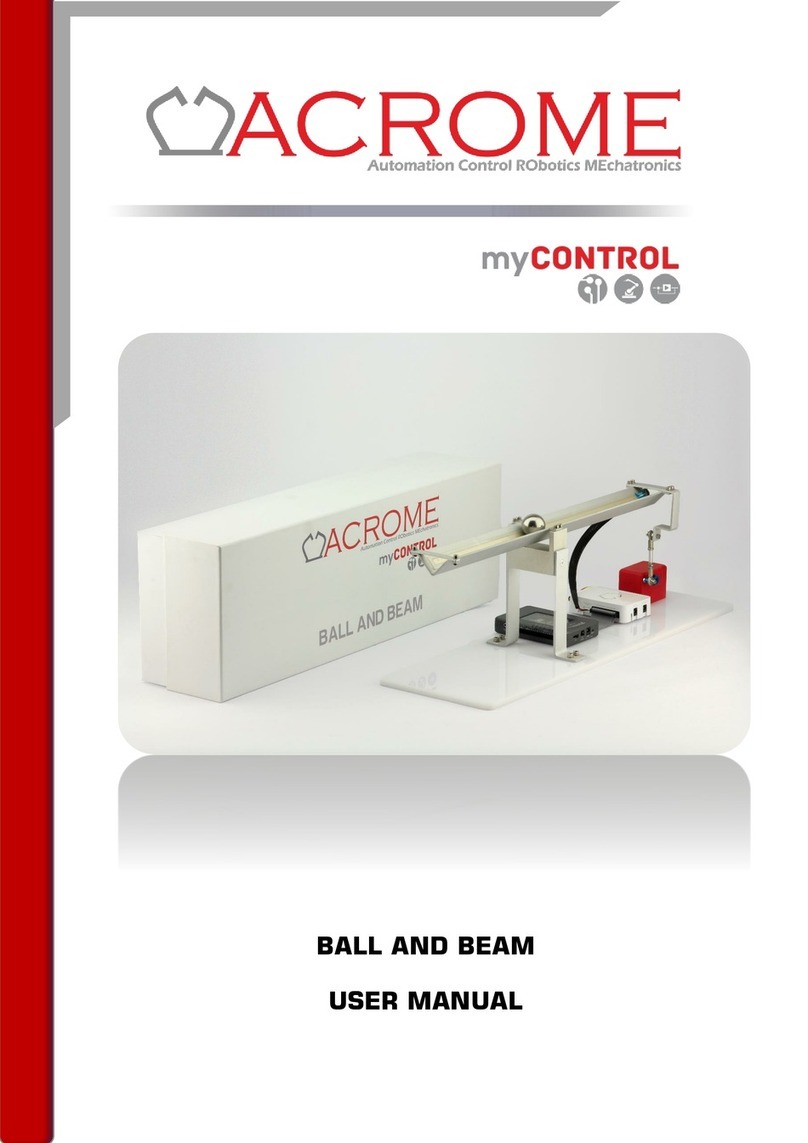

1 OVERVIEW..................................................................................................................................... 4

1.1 System Description........................................................................................................... 4

2 COMPONENTS .............................................................................................................................. 5

2.1 MPU-6050 Six-Axis (Gyro + Accelerometer) ........................................................................ 6

2.2 Linear Actuators .................................................................................................................... 6

2.3 Arduino Mega 2560............................................................................................................... 7

2.4 ACROME Power Distribution Box ......................................................................................... 7

3 TECHNICAL SPECIFICATIONS........................................................................................................ 8

4 WIRING.......................................................................................................................................... 9

4.1 Cable Names.......................................................................................................................... 9

4.2 Connections......................................................................................................................... 10

5 SETTING UP THE SYSTEM ........................................................................................................... 11

5.1 Getting Started .................................................................................................................... 11

5.2 Stewart_Pro Simulink Model .............................................................................................. 13

6. Device Parameters.................................................................................................................... 15