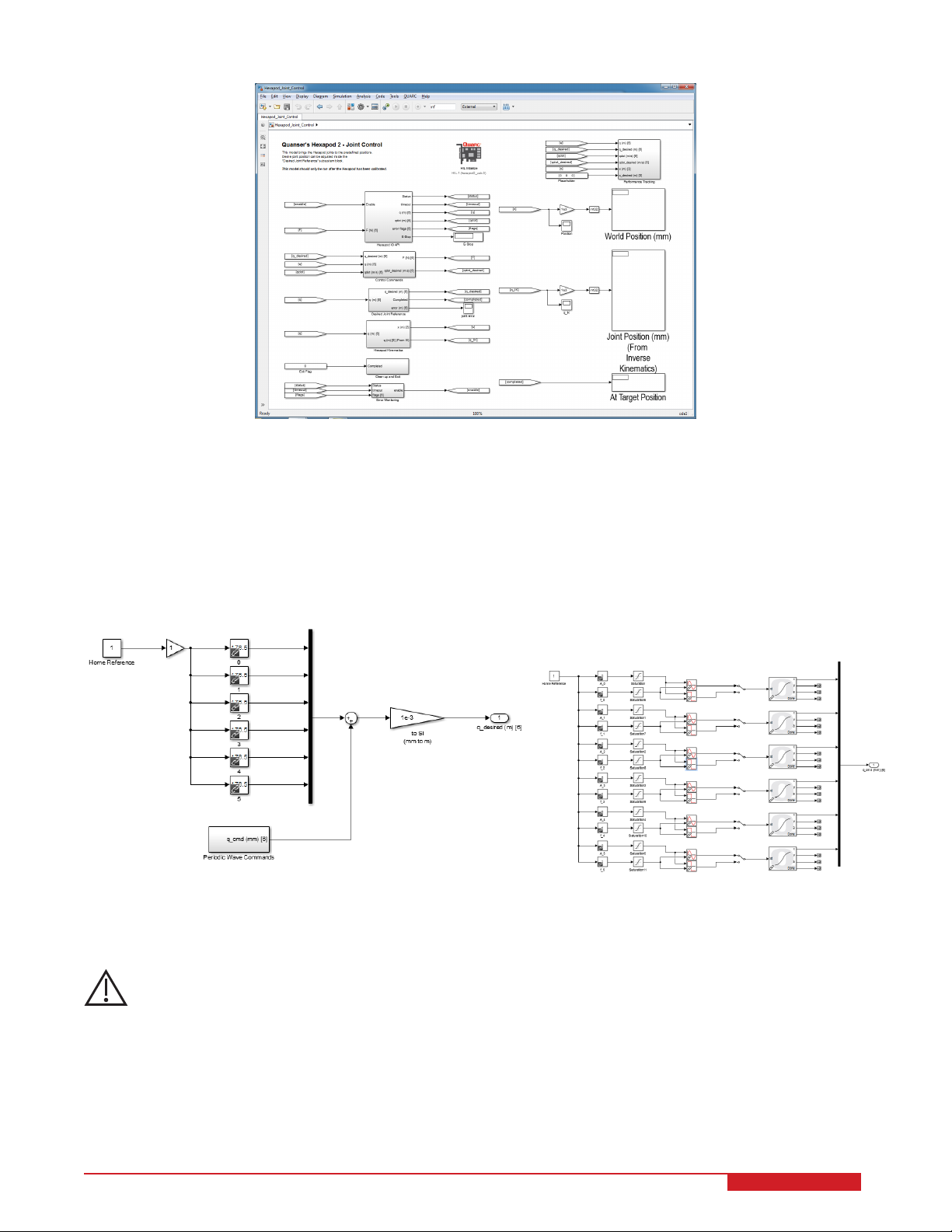

3. Open the Simulink model called Hexapod_Joint_Control.mdl, shown in Figure 2.3.

4. Run setup_hexapod.m in MATLAB (note: script is ran automatically when Simulink model is ran).

5. Click on QUARC | Build to generate the controller.

6. Run the QUARC controller by going to QUARC | Start.

7. Change the values of the Slider Gain blocks in in the Figure 2.4b gradually to begin commanding a sine wave

to the linear actuators.

Caution: PRESS DOWN on the RED BUTTON of the E-Stop switch to stop the Hexapod. This

deactivates the amplifier and cuts off the DC motor power.

8. Open the Joint Position Tracking and Joint Speed Tracking scopes, located in the Performance Tracking sub-

system, to examine the position or speed response of the Hexapod. The yellow trace is the measured posi-

tion/speed and the purple plot is the desired position/speed. To change which joint position/speed is being

displayed, set the Joint Index block between 1 and 6 accordingly. See Section 2.8.5 for more information.

9. Before stopping the controller, it is recommended to set position commands back to the home reference. That

is, set the Slider Gain blocks in the Periodic Wave Commands subsystem in Figure 2.4b all to 0 and the Constant

block in Figure 2.4a to 140 mm to bring the stage back to HOME position and ready for the next experimental

run.

Note: The Constant and Slider Gain block values for the setpoint commands are automatically reset to the

home reference automatically when the controller is stopped. However, because this is performed after the

controller is stopped, it does not physically move the platform back to HOME. This must be done manually as

the controller is still running.

10. Click on Stop button in the Simulink diagram tool bar to stop running the controller.

11. Shut off the Hexapod power switch if no more experiments will be conducted.

Note: As explained in the Hexapod User Manual [2], if a limit switch is triggered the amplifier automatically stops

accepting any motor/joint commands in that direction. However, position commands in the opposite direction are still

accepted (e.g., joint can be moved back to home).

The forward and inverse kinematics are included in Hexapod_Joint_Control.mdl to provide a comparison between

the measured joint positions, and those obtained using the derived kinematics. The World Position display block can

be used to monitor this world coordinate position. The Inverse Kinematics block is used to find the six joint positions

given the measured world coordinate position of the end-effector (i.e., the output from the Forward Kinematics block).

This joint space position vector can be monitored in the Hexapod Joints (From Inverse Kin) display and compared

to the actual joint positions shown in the Hexapod Joints display. See Section 2.8.4 for more information about the

kinematic blocks.

2.4 WORLD-SPACE POSITION CONTROL

This Hexapod_World_Control.mdl controller shown in Figure 2.5 controls the position of the upper stage, i.e., the

end-effector. The amplitude and frequency of the sine or square wave can be adjusted for each of the end-effector’s

axes: X, Y, Z, Pitch, Roll, and Yaw.

HEXAPOD Laboratory Guide v 1.3