3

1 General information ....................................................................................................4

1.1 Introduction .........................................................................................................4

1.2 Conventions ........................................................................................................4

1.3 Symbols and labels.............................................................................................5

1.4 Copyright protection............................................................................................5

1.5 Guarantee and warranty .....................................................................................5

2 Safety ............................................................................................................................6

2.1 Intended use .......................................................................................................6

2.2 Improper use.......................................................................................................6

2.3 Responsibility of the user....................................................................................7

2.4 General safety instructions .................................................................................7

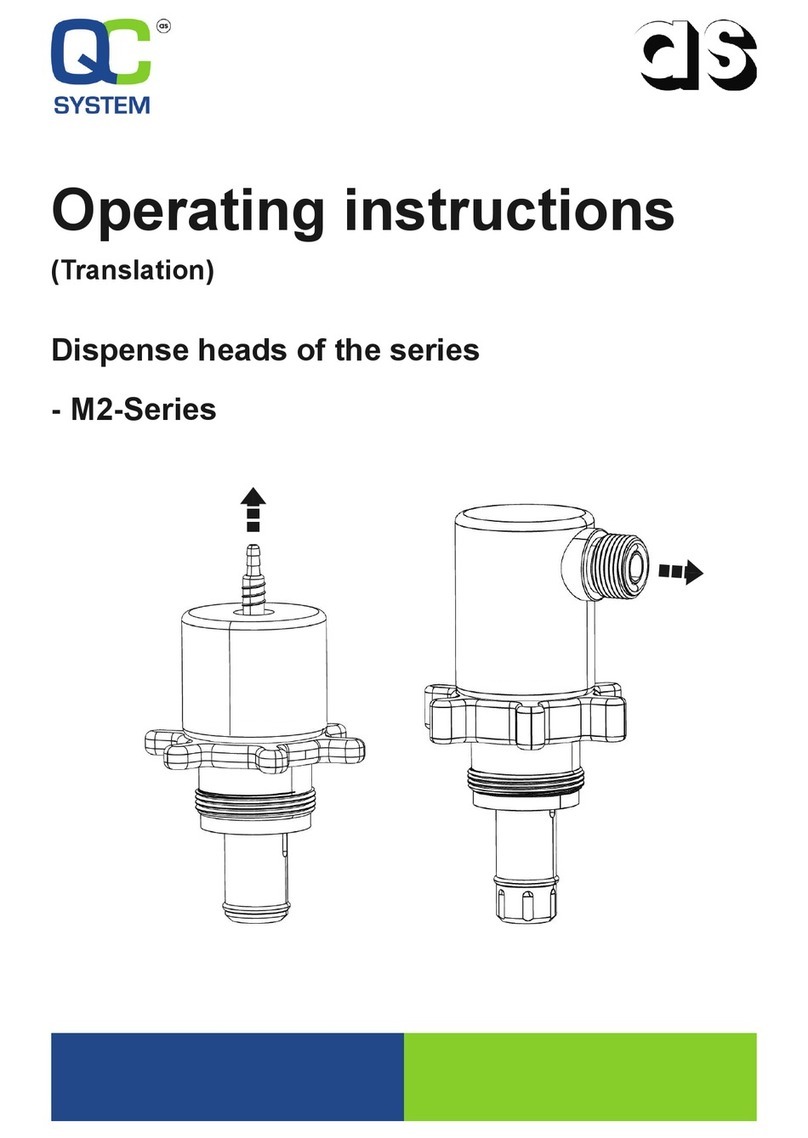

3 Setup / function ...........................................................................................................8

3.1 Auxiliary tools....................................................................................................11

4 Technical specications...........................................................................................12

4.1 Fill head DH-R.../GH-R... ..................................................................................12

4.2 Fill head DH-_B.../GH-_B.. ...............................................................................14

4.3 Fill head DH-A.../GH-A.. ...................................................................................16

4.4 Fill head DH-…-N2 / GH-…-N2 ........................................................................18

4.5 Fill head DH-_U… / GH-_U…...........................................................................20

4.6 Fill head DH-_J… / DH-J… / GH-_J… / GH-J…..............................................22

4.7 Ambient / operating temperature ......................................................................24

4.8 Torques for dip tube closures............................................................................24

5 Assembly / commissioning......................................................................................25

5.1 Initial commissioning.........................................................................................25

5.2 Tests prior to assembly .....................................................................................28

5.3 Mounting the ll head........................................................................................31

6 Operation....................................................................................................................35

6.1 Tests before each operation .............................................................................35

6.2 Tests during operation ......................................................................................35

7 Troubleshooting ........................................................................................................36

8 Disassembly...............................................................................................................37

8.1 Dismantling the ll head....................................................................................37

9 Maintenance / disposal .............................................................................................40

9.1 Cleaning the ll head ........................................................................................40

9.2 Fill head maintenance.......................................................................................40

9.3 Returning ll heads ...........................................................................................41

9.4 Fill head disposal ..............................................................................................41

Contents